| Availability: | |

|---|---|

| Quantity: | |

ZSP-A

ZT-PACK

Machine Name : Soy Sauce / Vinegar Low Viscous Liquid Filling Machine

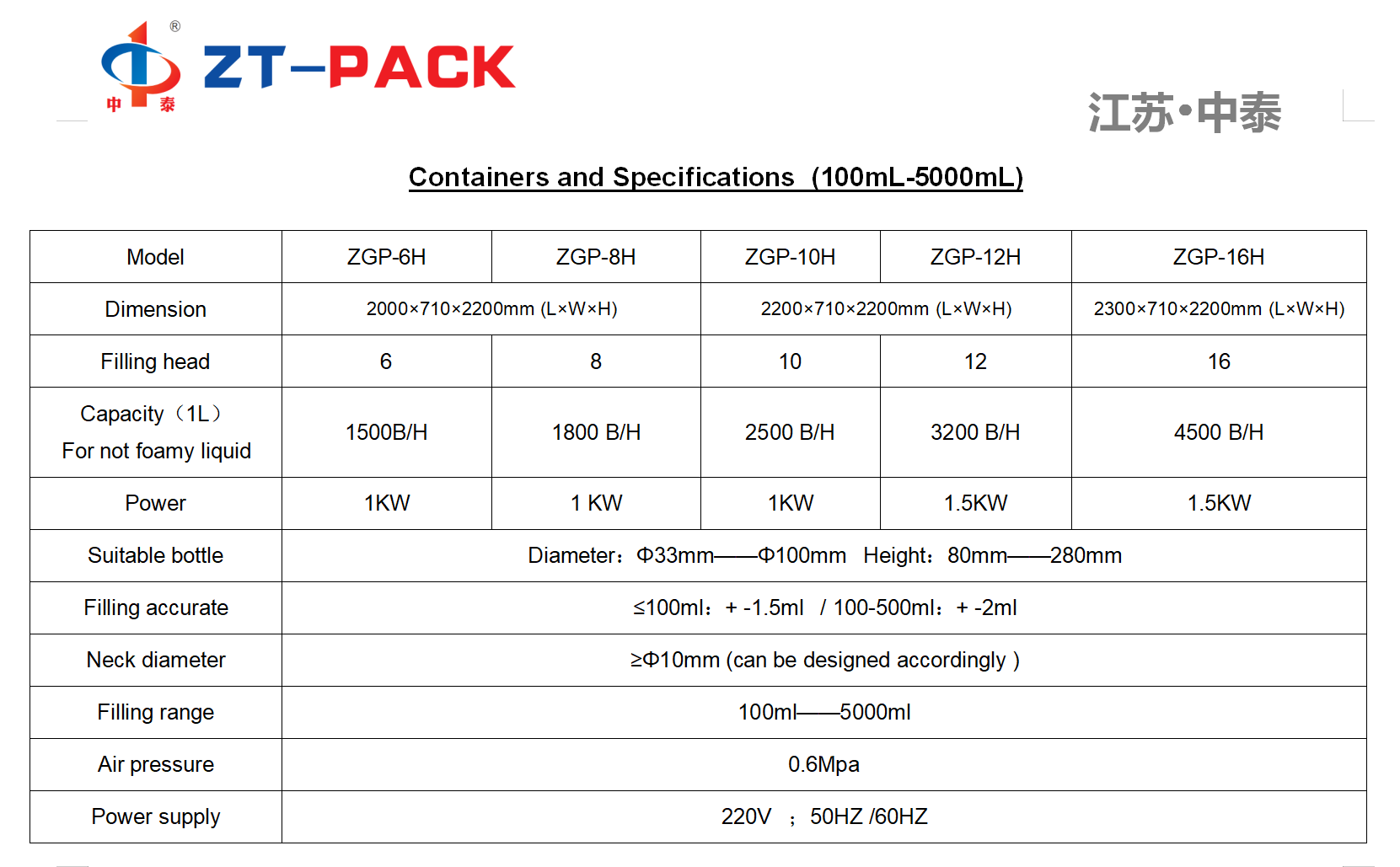

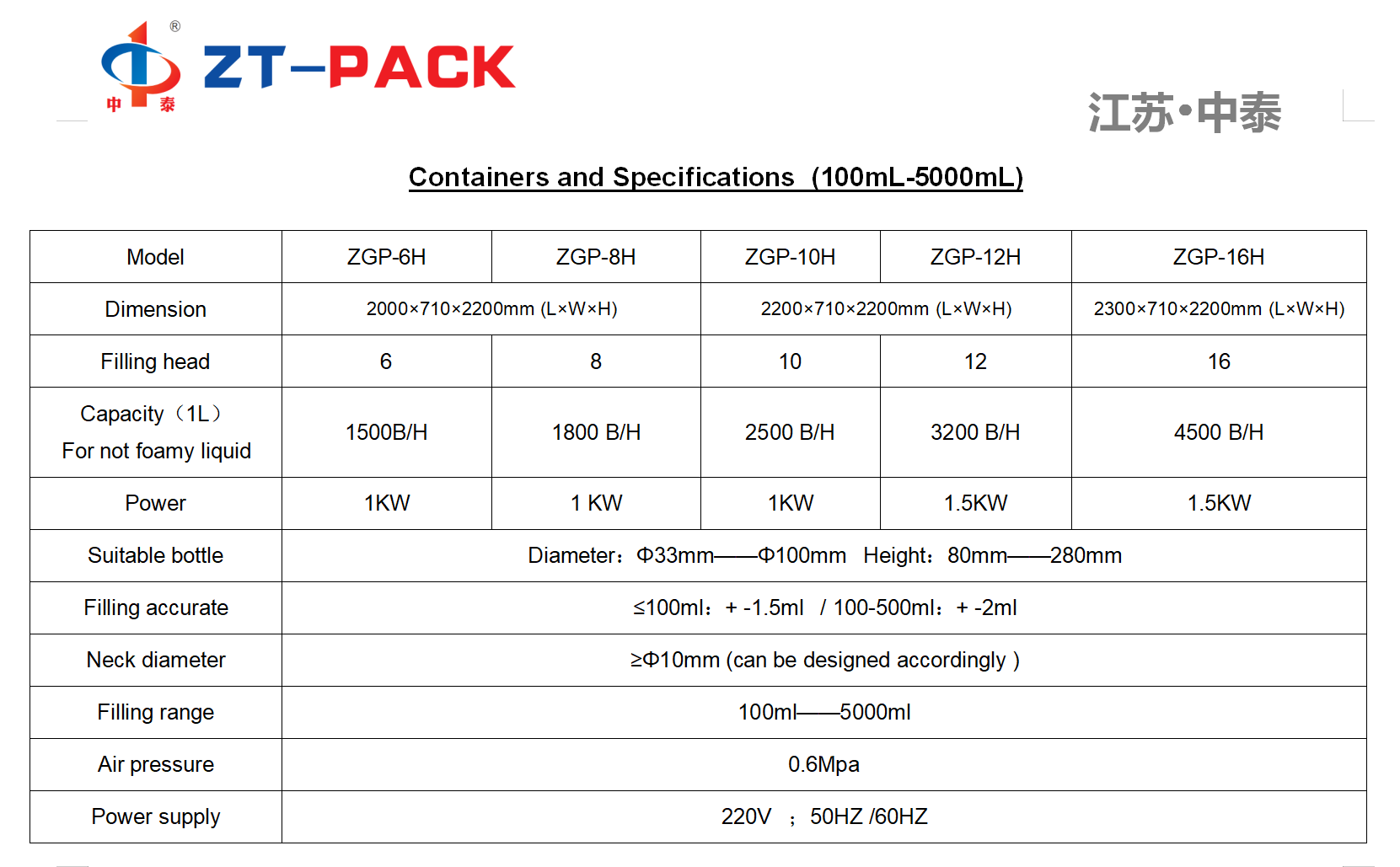

Type: ZGP-H

Suitable For Filling: Vinegar / Soy Sauce Flavor Water / Alcohol / Cooking Wine / Apple Cider Vinegar ...Etc kinds Products

Filling Range : 50ml-5000ml

Product description:

The time gravity filling machine is an affordable option for specific applications. It works well with liquids that have a low viscosity and remain consistent despite changes in temperature or batch. Examples of suitable liquids include water, vinegar, soy sauce, oil, alcohol, solvents, mouthwash, cleaners, bleach, and even corrosive chemicals.

The time flow filling machines operate on a simple principle. A holding tank situated above a series of pneumatically operated valves is filled with liquid. The master computer of the time flow filling machine independently times each valve, ensuring that the exact amount of liquid flows by gravity into the containers. The independent timing of each filling valve or nozzle adjusts for slight variations in flow rates, guaranteeing precise and accurate filling of each container. An automated product level sensing float system monitors the liquid level and maintains pressure, ensuring that the liquid flows uniformly and quickly into the containers. The pump is activated when the liquid level drops, and the holding tank is refilled. The pump deactivates when the liquid level reaches the high point.

Suitable for Fill :

Details pictures :

Optional Choosen : Meet CIP Cleaning requirements and GMP standard ![]()

Key Features :

Heavy-duty stainless steel constructed

Stainless steel Reservoir

Automatic Bottling Index kit with bottle counter

Pneumatic indexing gates (count in, count out)

Automatic product level sensing float system

Easily adjustable nozzle height settings accommodate vials to gallons

User friendly PLC controls with touch screen HMI

No bottle/No fill sensor

Bottle backup sensor (downstream) delays operation until jam is cleared

Able to output multiple doses per container for large containers

Easy clean stainless steel quick connect fittings

Drip Tray

Diving heads nozzles for bottom up filling to reduce foam

Neck grabbers for containers with small opening

Specifications are subject to change without notice, All rights are reserved.

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

Machine Name : Soy Sauce / Vinegar Low Viscous Liquid Filling Machine

Type: ZGP-H

Suitable For Filling: Vinegar / Soy Sauce Flavor Water / Alcohol / Cooking Wine / Apple Cider Vinegar ...Etc kinds Products

Filling Range : 50ml-5000ml

Product description:

The time gravity filling machine is an affordable option for specific applications. It works well with liquids that have a low viscosity and remain consistent despite changes in temperature or batch. Examples of suitable liquids include water, vinegar, soy sauce, oil, alcohol, solvents, mouthwash, cleaners, bleach, and even corrosive chemicals.

The time flow filling machines operate on a simple principle. A holding tank situated above a series of pneumatically operated valves is filled with liquid. The master computer of the time flow filling machine independently times each valve, ensuring that the exact amount of liquid flows by gravity into the containers. The independent timing of each filling valve or nozzle adjusts for slight variations in flow rates, guaranteeing precise and accurate filling of each container. An automated product level sensing float system monitors the liquid level and maintains pressure, ensuring that the liquid flows uniformly and quickly into the containers. The pump is activated when the liquid level drops, and the holding tank is refilled. The pump deactivates when the liquid level reaches the high point.

Suitable for Fill :

Details pictures :

Optional Choosen : Meet CIP Cleaning requirements and GMP standard ![]()

Key Features :

Heavy-duty stainless steel constructed

Stainless steel Reservoir

Automatic Bottling Index kit with bottle counter

Pneumatic indexing gates (count in, count out)

Automatic product level sensing float system

Easily adjustable nozzle height settings accommodate vials to gallons

User friendly PLC controls with touch screen HMI

No bottle/No fill sensor

Bottle backup sensor (downstream) delays operation until jam is cleared

Able to output multiple doses per container for large containers

Easy clean stainless steel quick connect fittings

Drip Tray

Diving heads nozzles for bottom up filling to reduce foam

Neck grabbers for containers with small opening

Specifications are subject to change without notice, All rights are reserved.

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com