| Availability: | |

|---|---|

| Quantity: | |

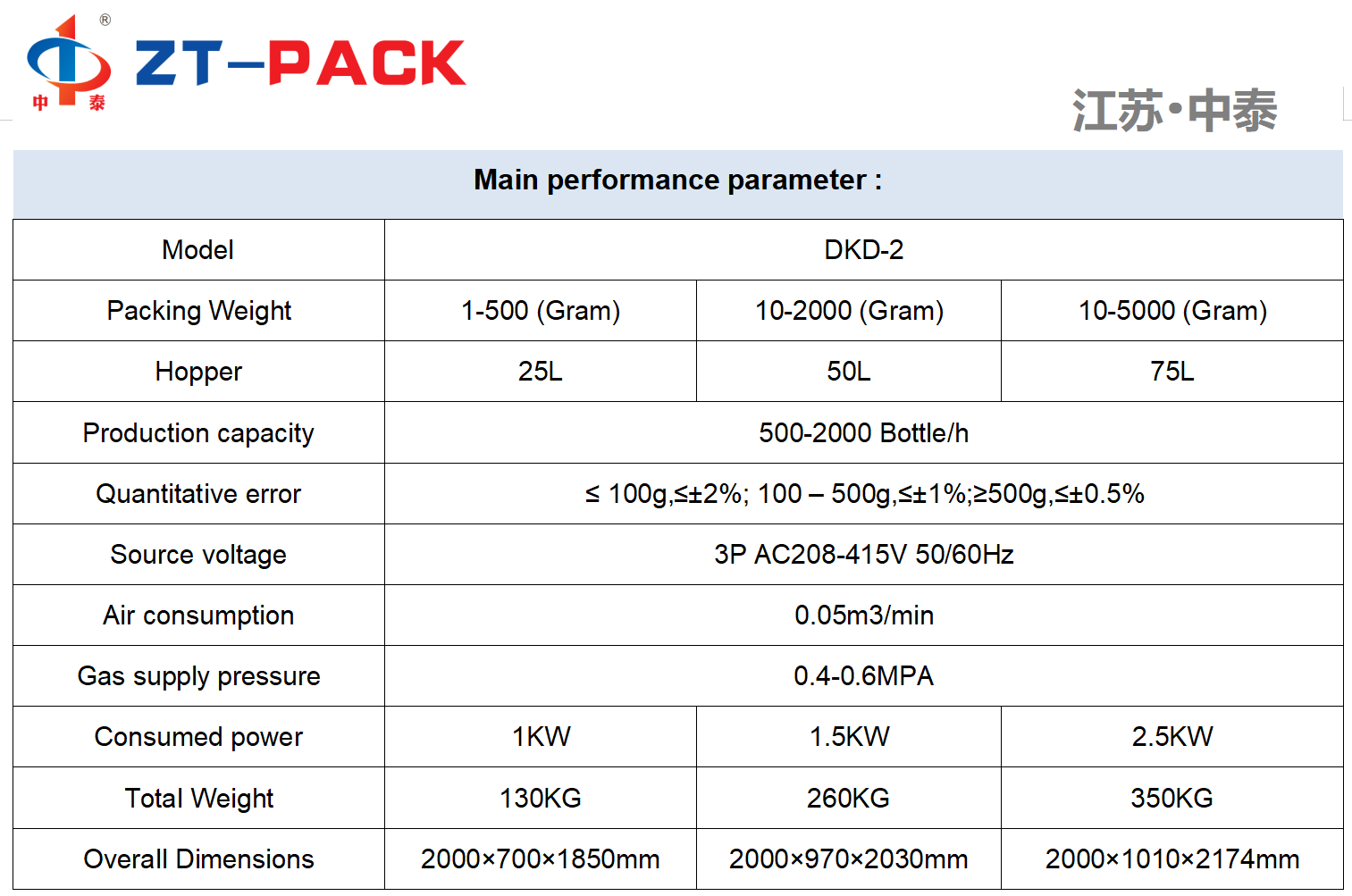

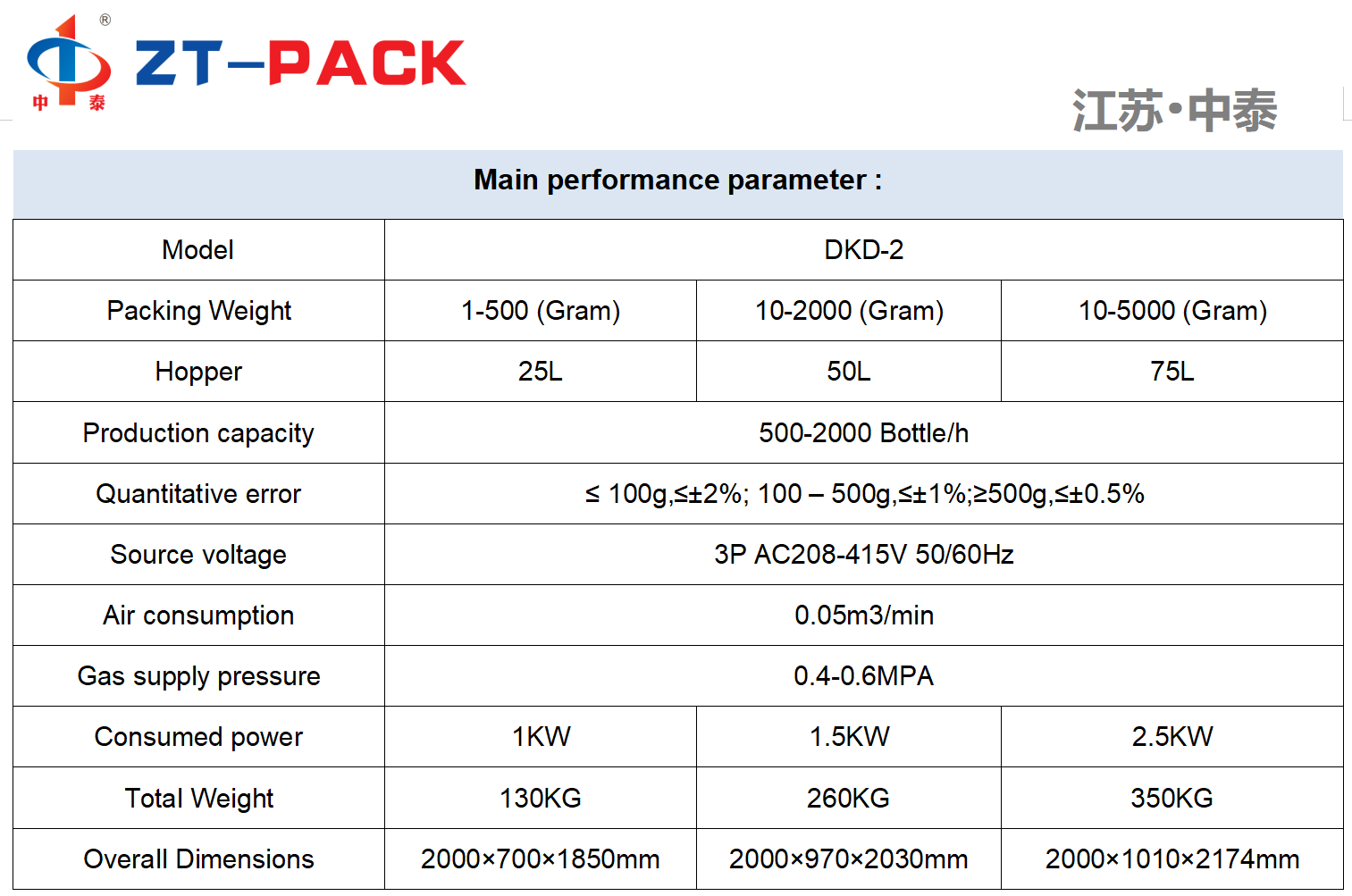

DKD-2

ZT-PACK

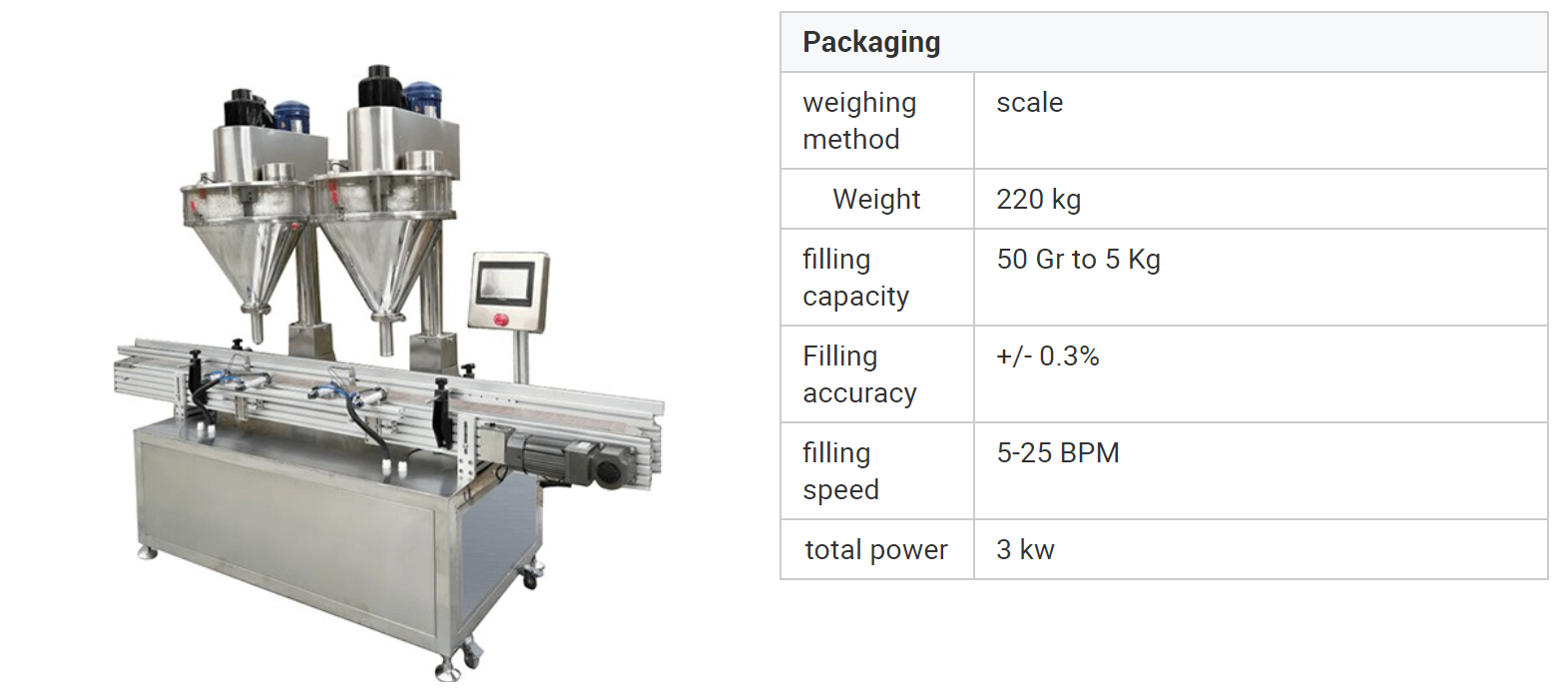

Machine Name : Full Automatic Powder Jar Filling Machine

Type: DKD-2

Product description:

ZT-PACK automatic powder filler for Jar is suitable for filling fluidic or low-fluidity powder materials like coffee powder, milk powder, granular additive, etc. It's widely used in the various industry including pharmaceutical, foodstuff, cosmetic and chemicals.

This machine adopts high-precision cam indexingProvide indexing and equalizing plate positioning plug mechanism;Acceleration cam drive provides capping head lift; constant torque capping;

High-precision screw metering filling; touch screen control bottle filling, no inner plug, outer cap. It has the advantages of accurate positioning, stable transmission, protective cap, and accurate measurement. It is easy to operate and fully meets the requirements of national GMP.

This machine can measure and fill powder and granular. It consists of a filling head, an independent electric chain conveyor and a pneumatic positioning system, and can form a complete filling line with a bottle unscrambler, capping machine, labeling machine, etc. Suitable for fluid or low fluidity materials, such as milk/protein powder, veterinary medicine, condiments, powdered additives, glucose, solid beverage, talcum powder, pesticides, etc.

Details pictures :

Key Features :

With two capacity models, one is for 1 - 500g filling weight, another is for 10 - 5000g filling weight.

Stainless steel structure.

PLC control system accessed through an easy-to-use touch screw with a weight module controller.

Up to 10 sets of operating parameters can be stored.

Servo motor drive auger with up to 99% filling precision.

Include a handwheel of adjustable filling nozzle height.

No bottle no fill.

Auger Powder Feeder is optional.

Equipped with a Siemens PLC and Touch Screen control, Panasonic / ABB / Siemens motors and Banner sensors.

No cap no bottle.

No bottle no cap.

A vibrating cap sorting system, as well as a high-tech automatic mechanical arm, make the loading operation more precise, which prevents cross-threading.

Adjustable torque.

Simple and easy to change parts facilitate the adjustment between different sizes of bottles and caps.

Stainless steel construction to meet GMP standard.

Custom design is available.

Specifications are subject to change without notice, All rights are reserved.

Suitable For Fill :

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

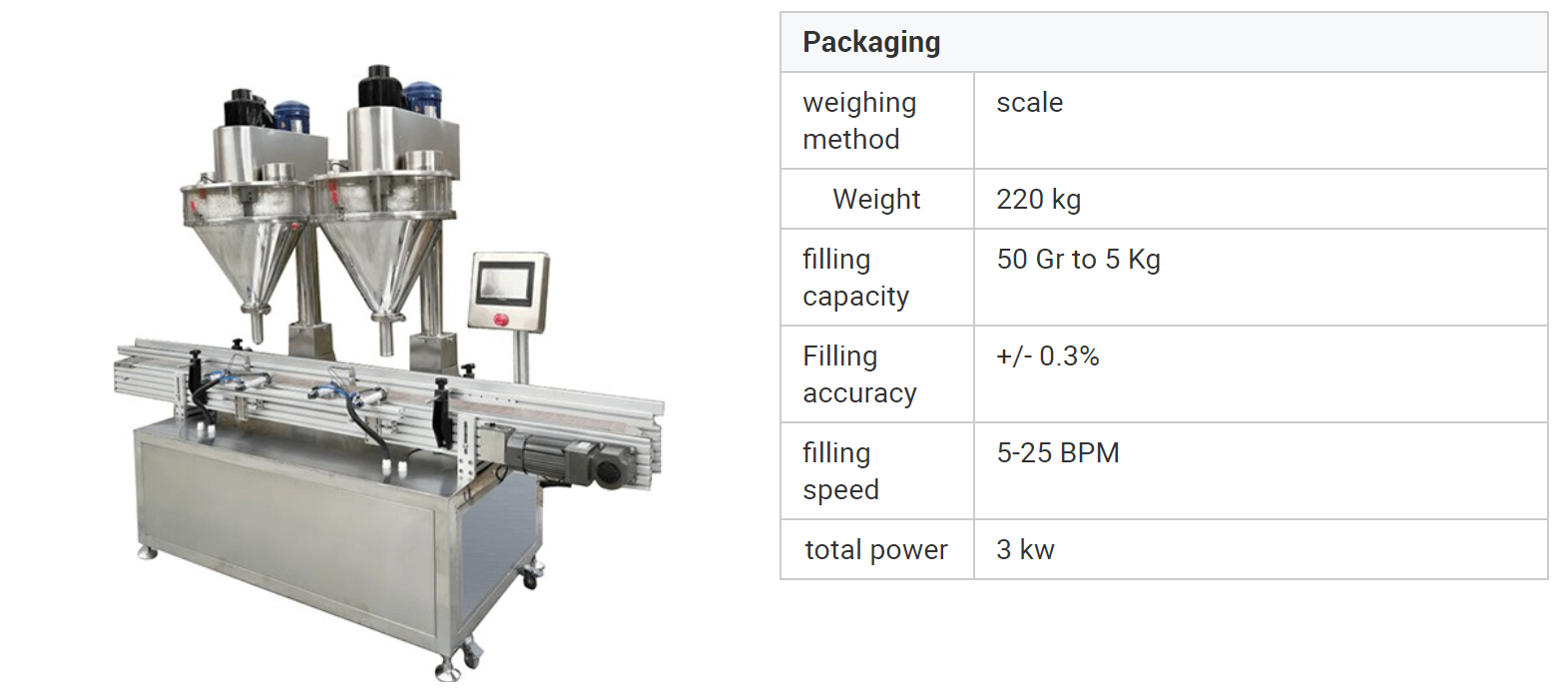

Machine Name : Full Automatic Powder Jar Filling Machine

Type: DKD-2

Product description:

ZT-PACK automatic powder filler for Jar is suitable for filling fluidic or low-fluidity powder materials like coffee powder, milk powder, granular additive, etc. It's widely used in the various industry including pharmaceutical, foodstuff, cosmetic and chemicals.

This machine adopts high-precision cam indexingProvide indexing and equalizing plate positioning plug mechanism;Acceleration cam drive provides capping head lift; constant torque capping;

High-precision screw metering filling; touch screen control bottle filling, no inner plug, outer cap. It has the advantages of accurate positioning, stable transmission, protective cap, and accurate measurement. It is easy to operate and fully meets the requirements of national GMP.

This machine can measure and fill powder and granular. It consists of a filling head, an independent electric chain conveyor and a pneumatic positioning system, and can form a complete filling line with a bottle unscrambler, capping machine, labeling machine, etc. Suitable for fluid or low fluidity materials, such as milk/protein powder, veterinary medicine, condiments, powdered additives, glucose, solid beverage, talcum powder, pesticides, etc.

Details pictures :

Key Features :

With two capacity models, one is for 1 - 500g filling weight, another is for 10 - 5000g filling weight.

Stainless steel structure.

PLC control system accessed through an easy-to-use touch screw with a weight module controller.

Up to 10 sets of operating parameters can be stored.

Servo motor drive auger with up to 99% filling precision.

Include a handwheel of adjustable filling nozzle height.

No bottle no fill.

Auger Powder Feeder is optional.

Equipped with a Siemens PLC and Touch Screen control, Panasonic / ABB / Siemens motors and Banner sensors.

No cap no bottle.

No bottle no cap.

A vibrating cap sorting system, as well as a high-tech automatic mechanical arm, make the loading operation more precise, which prevents cross-threading.

Adjustable torque.

Simple and easy to change parts facilitate the adjustment between different sizes of bottles and caps.

Stainless steel construction to meet GMP standard.

Custom design is available.

Specifications are subject to change without notice, All rights are reserved.

Suitable For Fill :

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

Technological innovation

Zhongtai company always insist to do elaboration and stronger, taking the principle path of professional development, to establish a modern enterprise as the goal, accelerating technological innovation, improve the management ability, the quality management system standards and in strict accordance with the requirements of operation, providing customers with advanced technology, quality and reliable performance of equipment and excellent service. Zhongtai company is always your sincerity, win-win, responsible partner, welcome the domestic and foreign merchants to guide, to discuss ,to choose and buy.

Lifelong service

The supplier is responsible for dispatching persons to debug and train worker in situ. After qualifying, the demand writes up the acceptance report.

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com