| Availability: | |

|---|---|

| Quantity: | |

ZGP-H

ZT-PACK

Machine Name : Mouthwash Oral Liquid Alcohol Gravity Filling Machine

Type: ZGP-H

Suitable For Filling: Glass Cleaner / Disinfectant / Multi Purpose Cleaner / Hand Sanitizer Alcohol Liquid / Mouthwash / Air Freshener / Antiseptic ...Etc low viscous kinds Products

Filling Range : 50ml-5000ml

Product description:

This is Gravity Type Time Control Filling Machine Suitable For : Low viscous density liquids such as : mouth water , oral liquid , alcohol spray ...

With special function for foamy solution : Diving system + Foamy sucking system

To make sure the filling speed faster and filling level the same

It applies 50ml-5000ml liquid for filling low viscous products .

It is produced with the GMP standards, safety, environmental hygienism, beautiful and adapt to different kinds of work place.

All the parts which contact with the filling material are made of stainless steel. The surface is polished . It has polished . It has nice appearance ,(in addition ,it may add full close equipment )

1、Advanced design

1.1 The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes.

1.2 Short filling circle, high production capacity.

1.3 Changing filling circle, high production capacity.

1.4 User may choose the filling volume and decide the filling heads per own production capacity.

1.5 The touching operation color screen, can display the production state, operation procedures and filling ways, tableau objective, operation simple and maintenance convenient.

1.6 Each filling-head is equipped with a bottle-mouth-clamping device, ensuring the injecting material correct aiming at.

Suitable for Fill :

Details pictures :

Key Features :

Heavy-duty stainless steel constructed

Stainless steel Reservoir

Automatic Bottling Index kit with bottle counter

Pneumatic indexing gates (count in, count out)

Automatic product level sensing float system

Easily adjustable nozzle height settings accommodate vials to gallons

User friendly PLC controls with touch screen HMI

No bottle/No fill sensor

Bottle backup sensor (downstream) delays operation until jam is cleared

Able to output multiple doses per container for large containers

Easy clean stainless steel quick connect fittings

Drip Tray

Diving heads nozzles for bottom up filling to reduce foam

Neck grabbers for containers with small opening

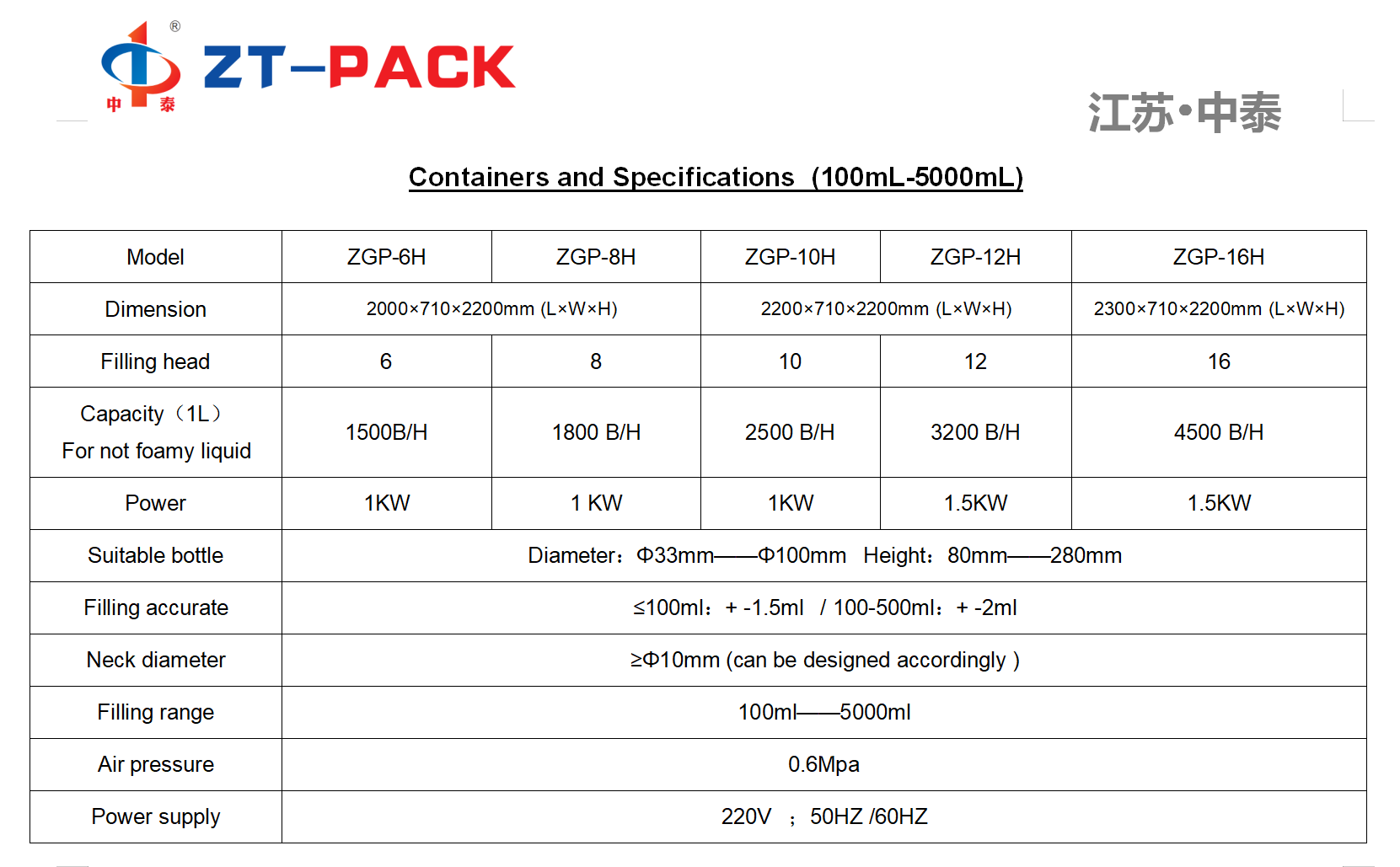

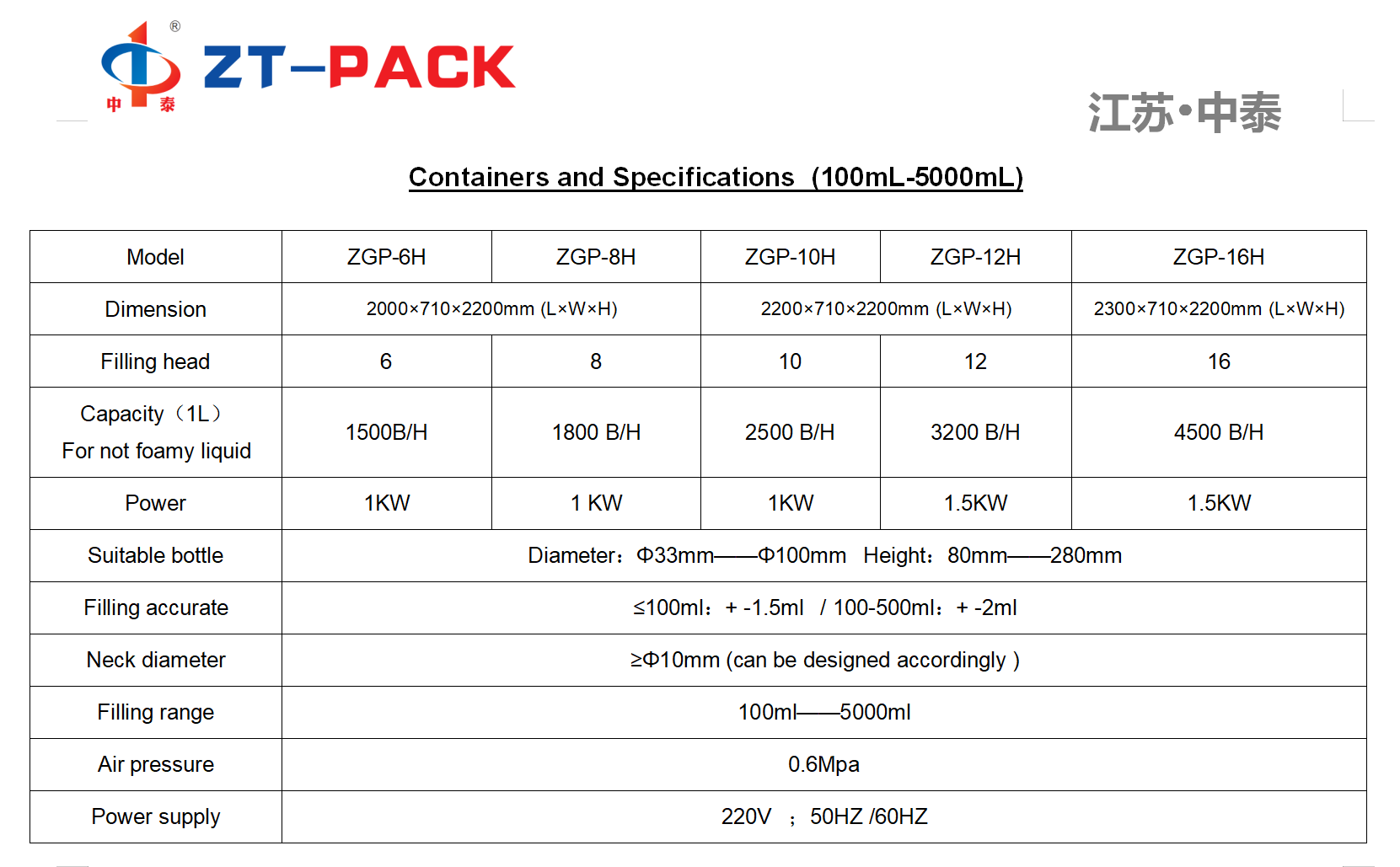

Specifications are subject to change without notice, All rights are reserved.

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

Machine Name : Mouthwash Oral Liquid Alcohol Gravity Filling Machine

Type: ZGP-H

Suitable For Filling: Glass Cleaner / Disinfectant / Multi Purpose Cleaner / Hand Sanitizer Alcohol Liquid / Mouthwash / Air Freshener / Antiseptic ...Etc low viscous kinds Products

Filling Range : 50ml-5000ml

Product description:

This is Gravity Type Time Control Filling Machine Suitable For : Low viscous density liquids such as : mouth water , oral liquid , alcohol spray ...

With special function for foamy solution : Diving system + Foamy sucking system

To make sure the filling speed faster and filling level the same

It applies 50ml-5000ml liquid for filling low viscous products .

It is produced with the GMP standards, safety, environmental hygienism, beautiful and adapt to different kinds of work place.

All the parts which contact with the filling material are made of stainless steel. The surface is polished . It has polished . It has nice appearance ,(in addition ,it may add full close equipment )

1、Advanced design

1.1 The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes.

1.2 Short filling circle, high production capacity.

1.3 Changing filling circle, high production capacity.

1.4 User may choose the filling volume and decide the filling heads per own production capacity.

1.5 The touching operation color screen, can display the production state, operation procedures and filling ways, tableau objective, operation simple and maintenance convenient.

1.6 Each filling-head is equipped with a bottle-mouth-clamping device, ensuring the injecting material correct aiming at.

Suitable for Fill :

Details pictures :

Key Features :

Heavy-duty stainless steel constructed

Stainless steel Reservoir

Automatic Bottling Index kit with bottle counter

Pneumatic indexing gates (count in, count out)

Automatic product level sensing float system

Easily adjustable nozzle height settings accommodate vials to gallons

User friendly PLC controls with touch screen HMI

No bottle/No fill sensor

Bottle backup sensor (downstream) delays operation until jam is cleared

Able to output multiple doses per container for large containers

Easy clean stainless steel quick connect fittings

Drip Tray

Diving heads nozzles for bottom up filling to reduce foam

Neck grabbers for containers with small opening

Specifications are subject to change without notice, All rights are reserved.

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com