| Availability: | |

|---|---|

| Quantity: | |

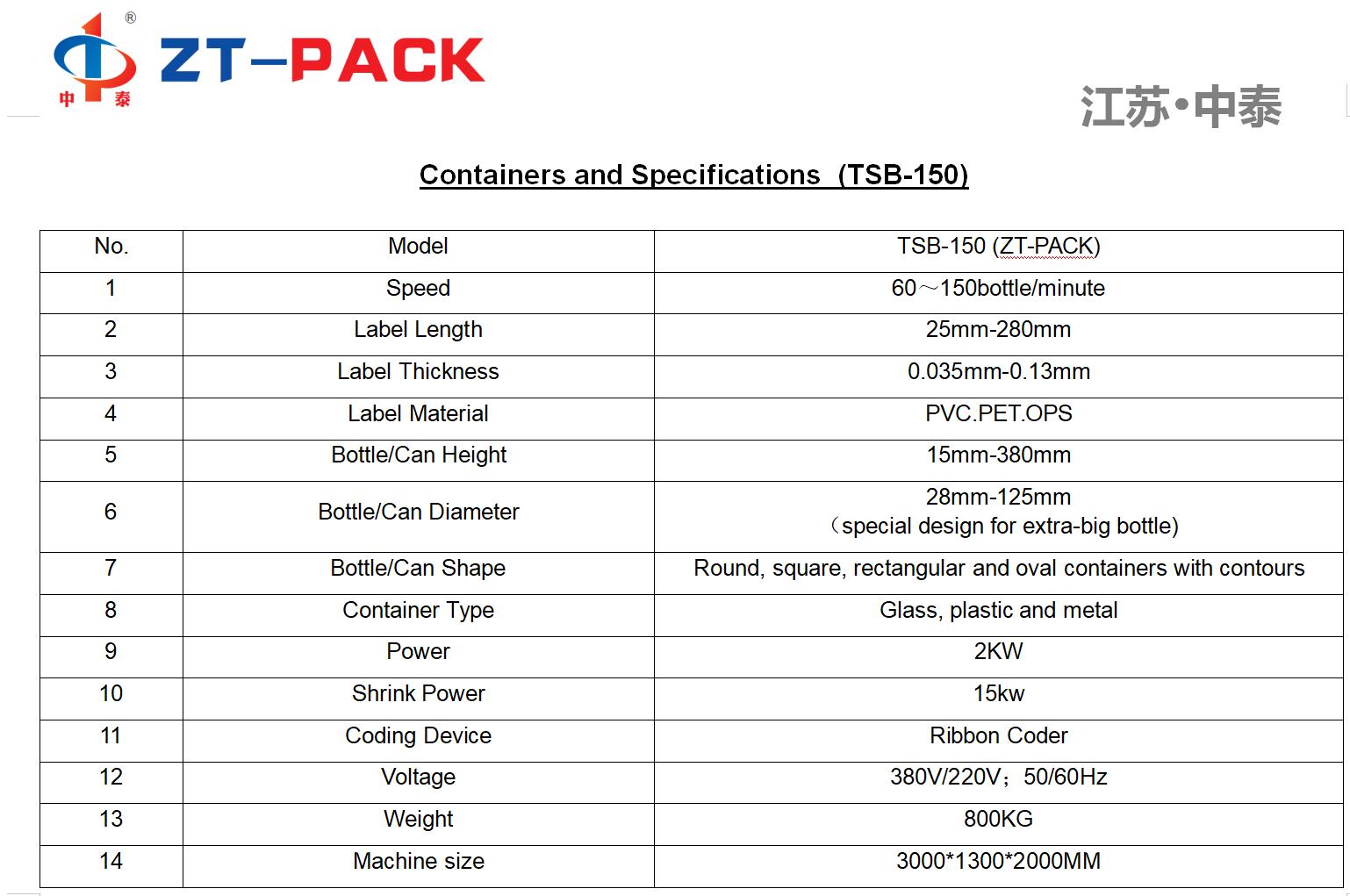

TSB-150

ZT-PACK

Machine Name : Automatic Shrink Sleeve Labeling Machine --Steam Type Single Layer Tunnel

Type: TSB-150

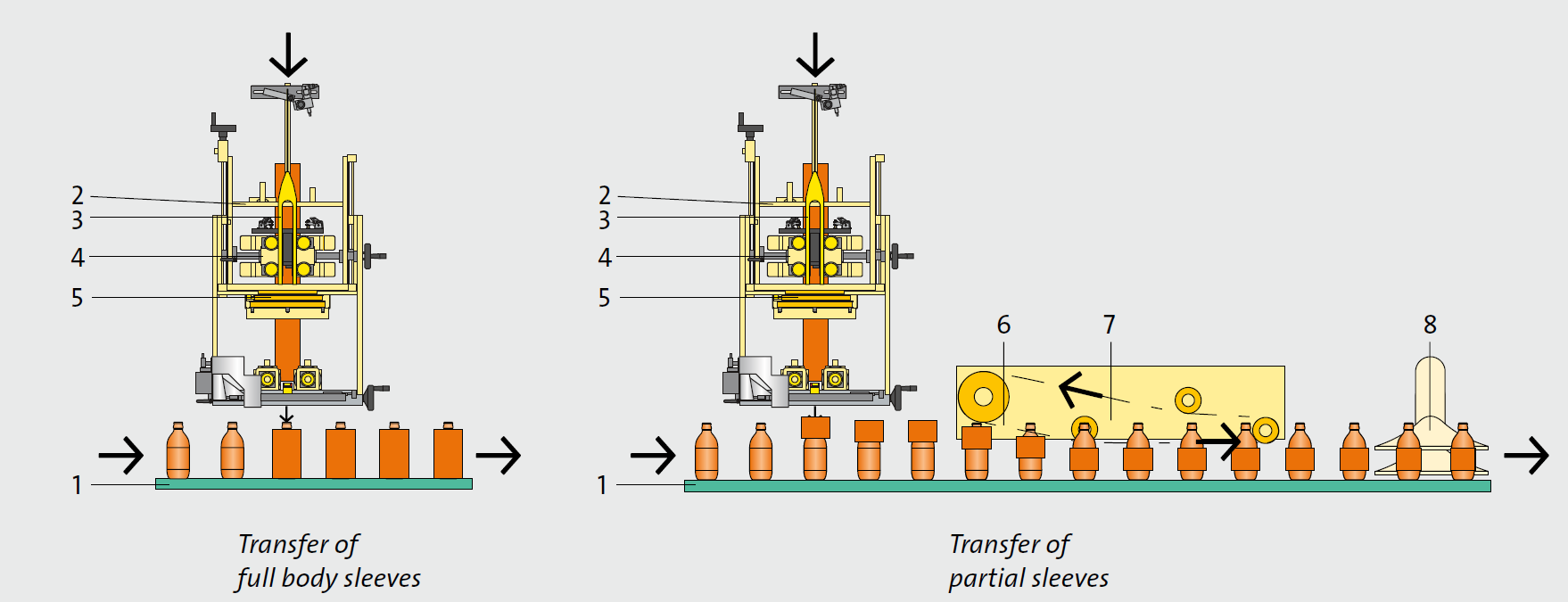

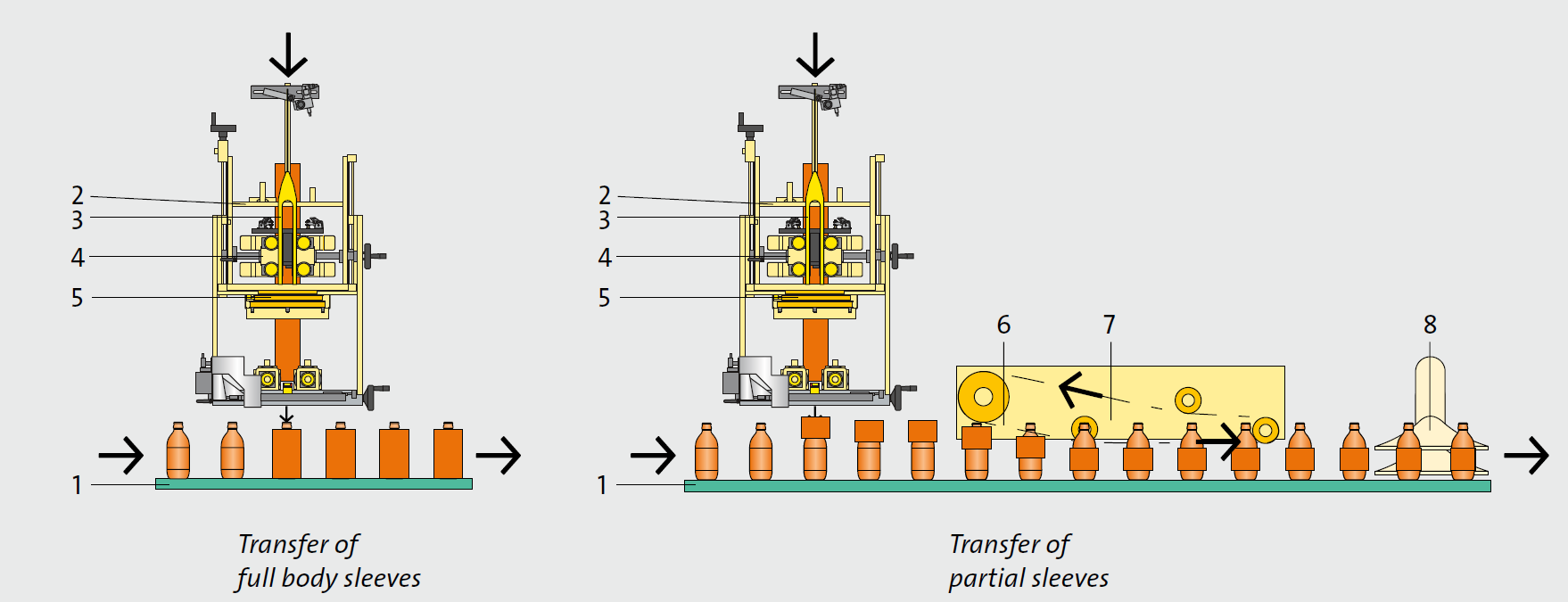

1.Container infeed

2 .Suspension for the cutting unit (height-adjustable)

3.Mandrel

4.Sleeve transport¬unit

5 Sleeve cutter unit with servo-controlled,rotating blades

6.Lowering belt

7.Device for positioning of the sleeves (optional)

8 Hot-air nozzles for pre-shrinking (optional)Unwinding and cutting of the film sleeve is performed. After cutting, a feed applies the open sleeves directly to the container.

Depending on the container shape and the sleeve size, an optional positioning module moves the sleeve to the desired position. Partial sleeves will be moved to their exact position by means of lateral guides. Optional hot-air nozzles shrink and pre-position the sleeves. After that, the sleeves are shaped perfectly around the container contour in a steam or hot-air tunnel.

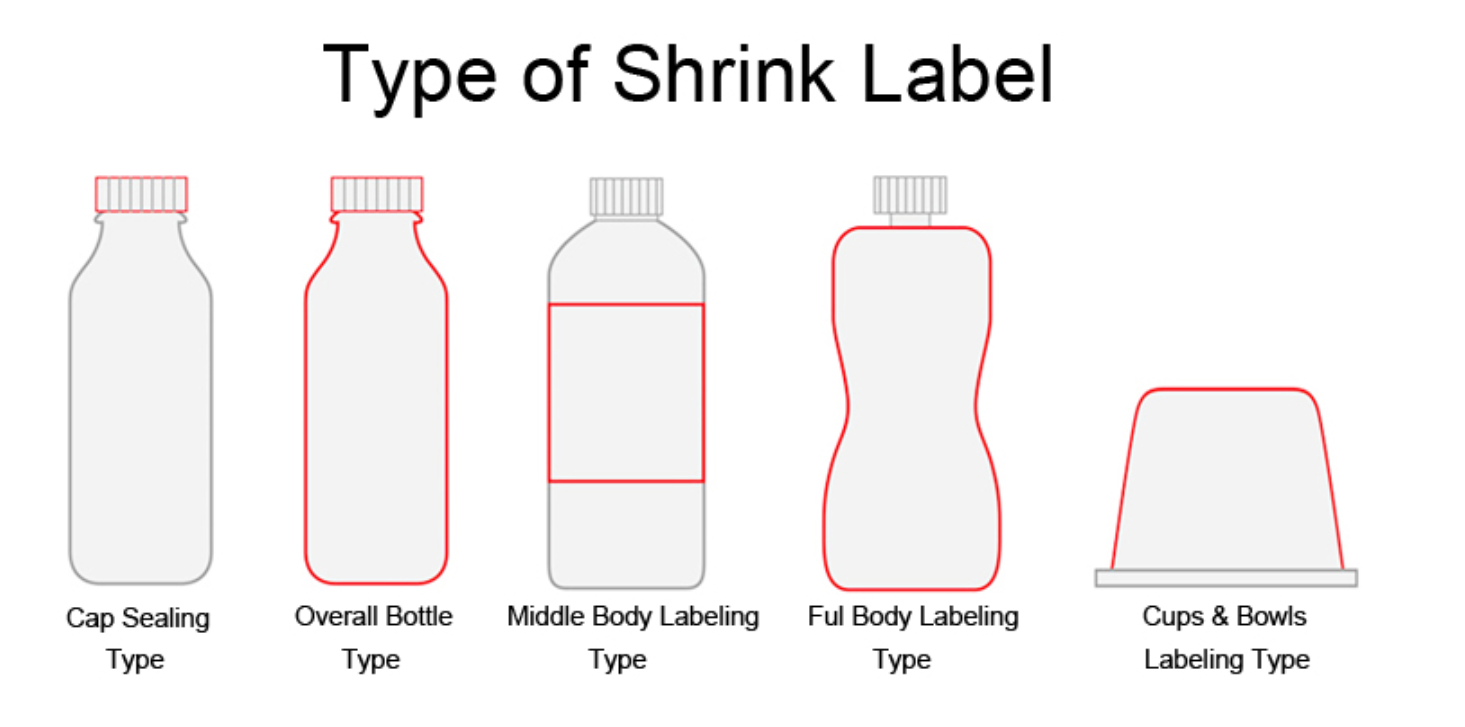

Labelling with shrinkable full body and partial sleeves

Machine Description :

Shrink sleeve labeler and shrink band equipment apply and shrink middle, full body sleeve labels or tamper evident bands made from PVC, PET/PETG, OPS, or PLA on a variety of empty or filled round, square and oval containers in plastic, glass or metal. It is a perfect solution for industries including beverage, food, pharmaceutical, nutraceutical, health and beauty, consumer goods, chemical, and other manufactured goods to decorate your products. Each shrink sleeve system includes a sleeve applicator, one or two shrink tunnel modules, a steam generator and a stainless steel conveyor for transporting containers through the system. Label sleeving machine is manufactured with stainless steel, servo motor and designed with servo driven, PLC controlled label drive rollers, cutter assembly, and label shooting wheels to provide accurate and consistent shrink sleeve labeling.

This machine adopts international advanced technology, cover the circle label on the bottles. And then hot shrinking to fix on the position which bottle body designed. It is controlled by micro-computer, automatic detection and position.

Major characteristics :

1.SUS304 stainless steel is used on whole machine body.Oxidation-treated aluminium alloy is adoptted to the inside structare,which will make the machine stainless and longevous

2.Unique cutter design , makes label cutting more smoothly.It is conenient to change the blade.

3.when meeting diffenent types of bottles,it can be fast to change mould.It will be more conuenient and stable toload and unload labels.

4.Frequency -controlled grouping bottle equipment makes botttle inlet more stable

5.Uninterrupted label-brushing system makes the precision more accurate .

6.combined the electric eye amplifier with enpennage,it ensures the least reeor of cutting labels.

7.Stand alone mateerial poriding system can adjnst the location of labels

8.Errors occlcrred durning working can be displayed on the touch screen .once solued,production will be factly recouered.

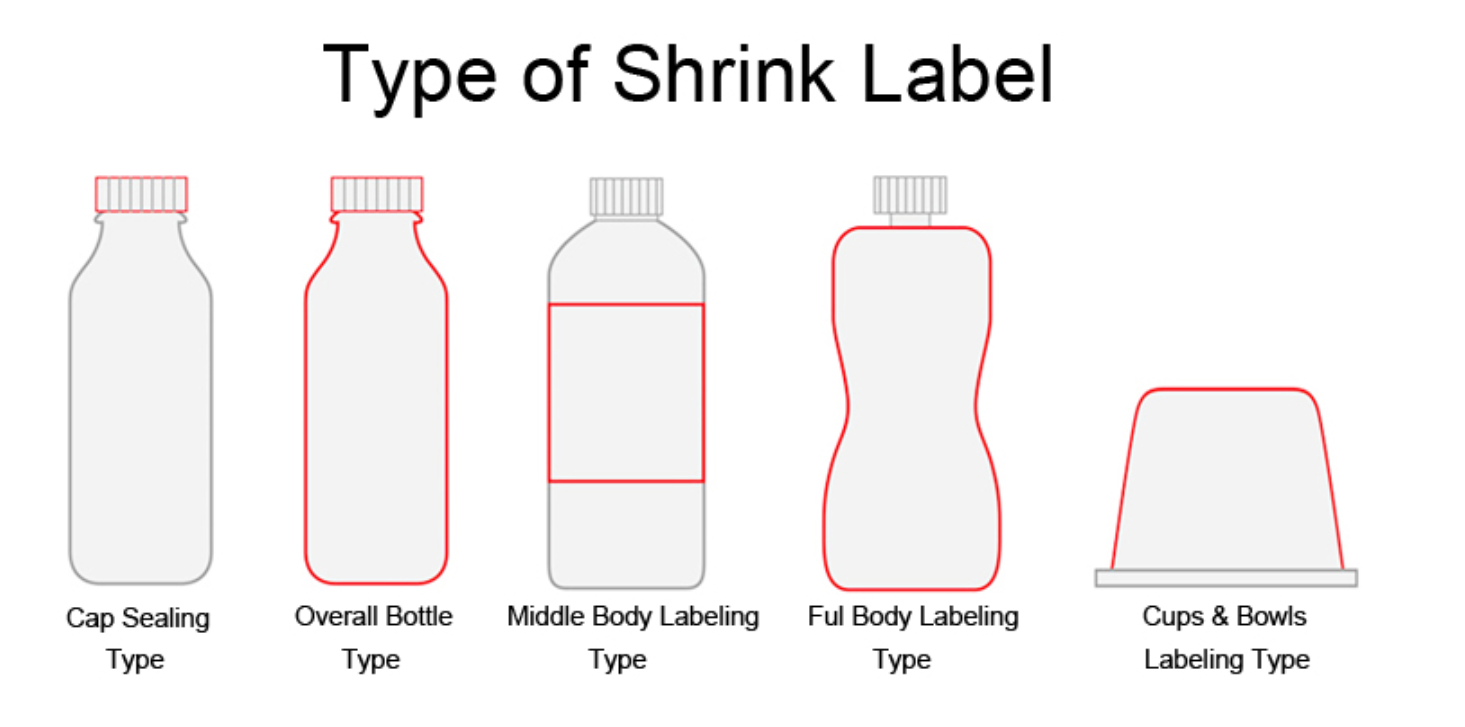

9. Suitable bottle shapes: round bottle, square bottle, elliptic bottle, top of bottle and body of bottle.

10. Applied to different kinds of plastic bottles, glass bottles, PVC, PET, PS, steel tins, etc for food, beverage, cleaning, medicine and liquor.

Features:

1.The machines use the advanced man-machine interface automatic control technology,the key electric elements adopt international famous products.

2.The machine operation, easy to adjust, can be used on production line.

3.The unique design of the knife plate within the scope of the specification, shall not be in knife block, by changing the blade fast and convenient.

4.The unique set of standard methods, using the compression type of label, convenient and reasonable. 5.The whole machine transmission type structure to make changing bottle is extremely convenient.

6.Suitable for 5 ~ 10 "the membrane material, uniform, efficient, and can do, stop action.

7.Can be used in the square and round bottles.

8.the elevating center pillar height is adjusted.

9.Using high sensitivity optical fiber electric eye, precision cut length.

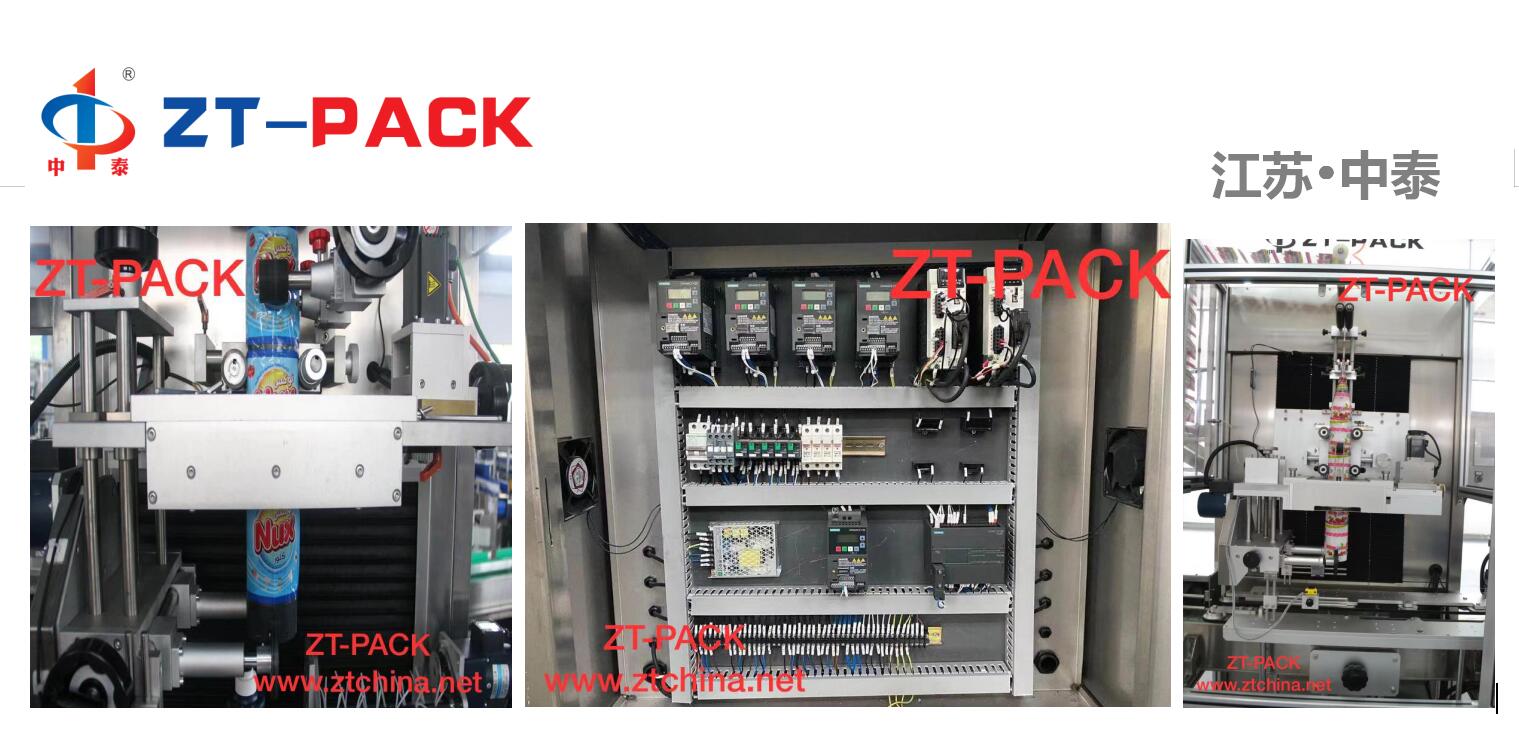

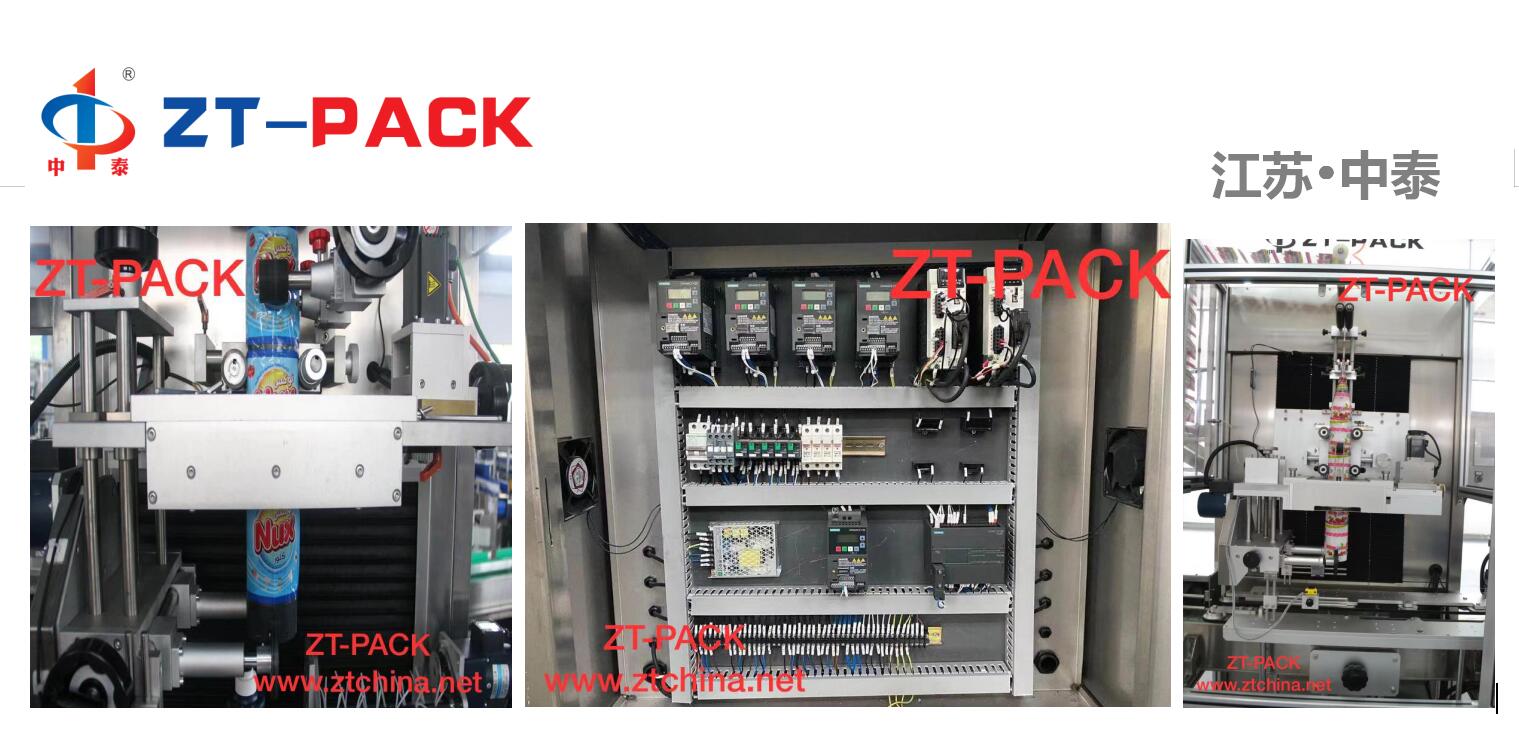

Details Pictures :

Suitable for :

Machine Name : Automatic Shrink Sleeve Labeling Machine --Steam Type Single Layer Tunnel

Type: TSB-150

1.Container infeed

2 .Suspension for the cutting unit (height-adjustable)

3.Mandrel

4.Sleeve transport¬unit

5 Sleeve cutter unit with servo-controlled,rotating blades

6.Lowering belt

7.Device for positioning of the sleeves (optional)

8 Hot-air nozzles for pre-shrinking (optional)Unwinding and cutting of the film sleeve is performed. After cutting, a feed applies the open sleeves directly to the container.

Depending on the container shape and the sleeve size, an optional positioning module moves the sleeve to the desired position. Partial sleeves will be moved to their exact position by means of lateral guides. Optional hot-air nozzles shrink and pre-position the sleeves. After that, the sleeves are shaped perfectly around the container contour in a steam or hot-air tunnel.

Labelling with shrinkable full body and partial sleeves

Machine Description :

Shrink sleeve labeler and shrink band equipment apply and shrink middle, full body sleeve labels or tamper evident bands made from PVC, PET/PETG, OPS, or PLA on a variety of empty or filled round, square and oval containers in plastic, glass or metal. It is a perfect solution for industries including beverage, food, pharmaceutical, nutraceutical, health and beauty, consumer goods, chemical, and other manufactured goods to decorate your products. Each shrink sleeve system includes a sleeve applicator, one or two shrink tunnel modules, a steam generator and a stainless steel conveyor for transporting containers through the system. Label sleeving machine is manufactured with stainless steel, servo motor and designed with servo driven, PLC controlled label drive rollers, cutter assembly, and label shooting wheels to provide accurate and consistent shrink sleeve labeling.

This machine adopts international advanced technology, cover the circle label on the bottles. And then hot shrinking to fix on the position which bottle body designed. It is controlled by micro-computer, automatic detection and position.

Major characteristics :

1.SUS304 stainless steel is used on whole machine body.Oxidation-treated aluminium alloy is adoptted to the inside structare,which will make the machine stainless and longevous

2.Unique cutter design , makes label cutting more smoothly.It is conenient to change the blade.

3.when meeting diffenent types of bottles,it can be fast to change mould.It will be more conuenient and stable toload and unload labels.

4.Frequency -controlled grouping bottle equipment makes botttle inlet more stable

5.Uninterrupted label-brushing system makes the precision more accurate .

6.combined the electric eye amplifier with enpennage,it ensures the least reeor of cutting labels.

7.Stand alone mateerial poriding system can adjnst the location of labels

8.Errors occlcrred durning working can be displayed on the touch screen .once solued,production will be factly recouered.

9. Suitable bottle shapes: round bottle, square bottle, elliptic bottle, top of bottle and body of bottle.

10. Applied to different kinds of plastic bottles, glass bottles, PVC, PET, PS, steel tins, etc for food, beverage, cleaning, medicine and liquor.

Features:

1.The machines use the advanced man-machine interface automatic control technology,the key electric elements adopt international famous products.

2.The machine operation, easy to adjust, can be used on production line.

3.The unique design of the knife plate within the scope of the specification, shall not be in knife block, by changing the blade fast and convenient.

4.The unique set of standard methods, using the compression type of label, convenient and reasonable. 5.The whole machine transmission type structure to make changing bottle is extremely convenient.

6.Suitable for 5 ~ 10 "the membrane material, uniform, efficient, and can do, stop action.

7.Can be used in the square and round bottles.

8.the elevating center pillar height is adjusted.

9.Using high sensitivity optical fiber electric eye, precision cut length.

Details Pictures :

Suitable for :

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com