| Availability: | |

|---|---|

| Quantity: | |

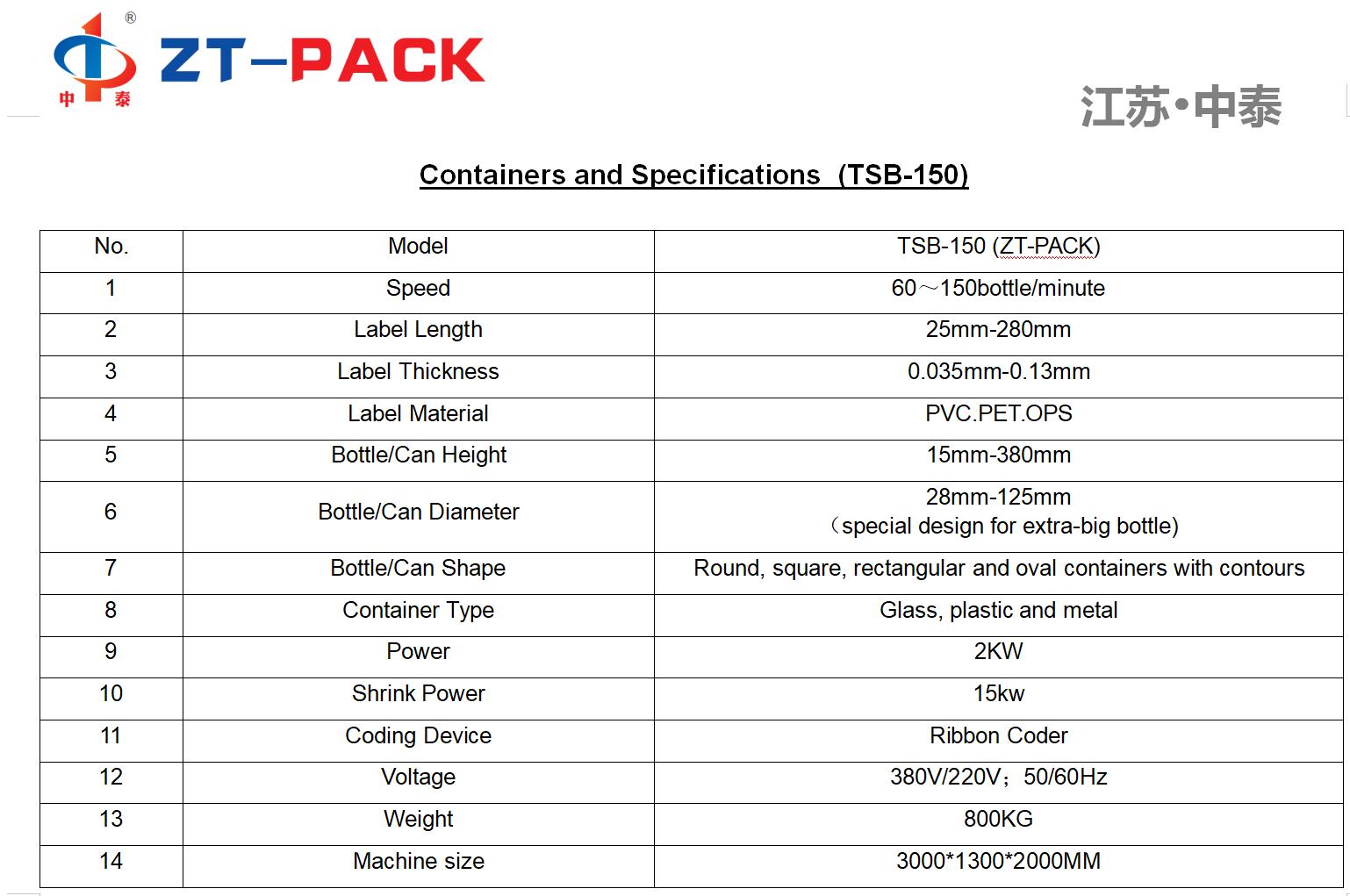

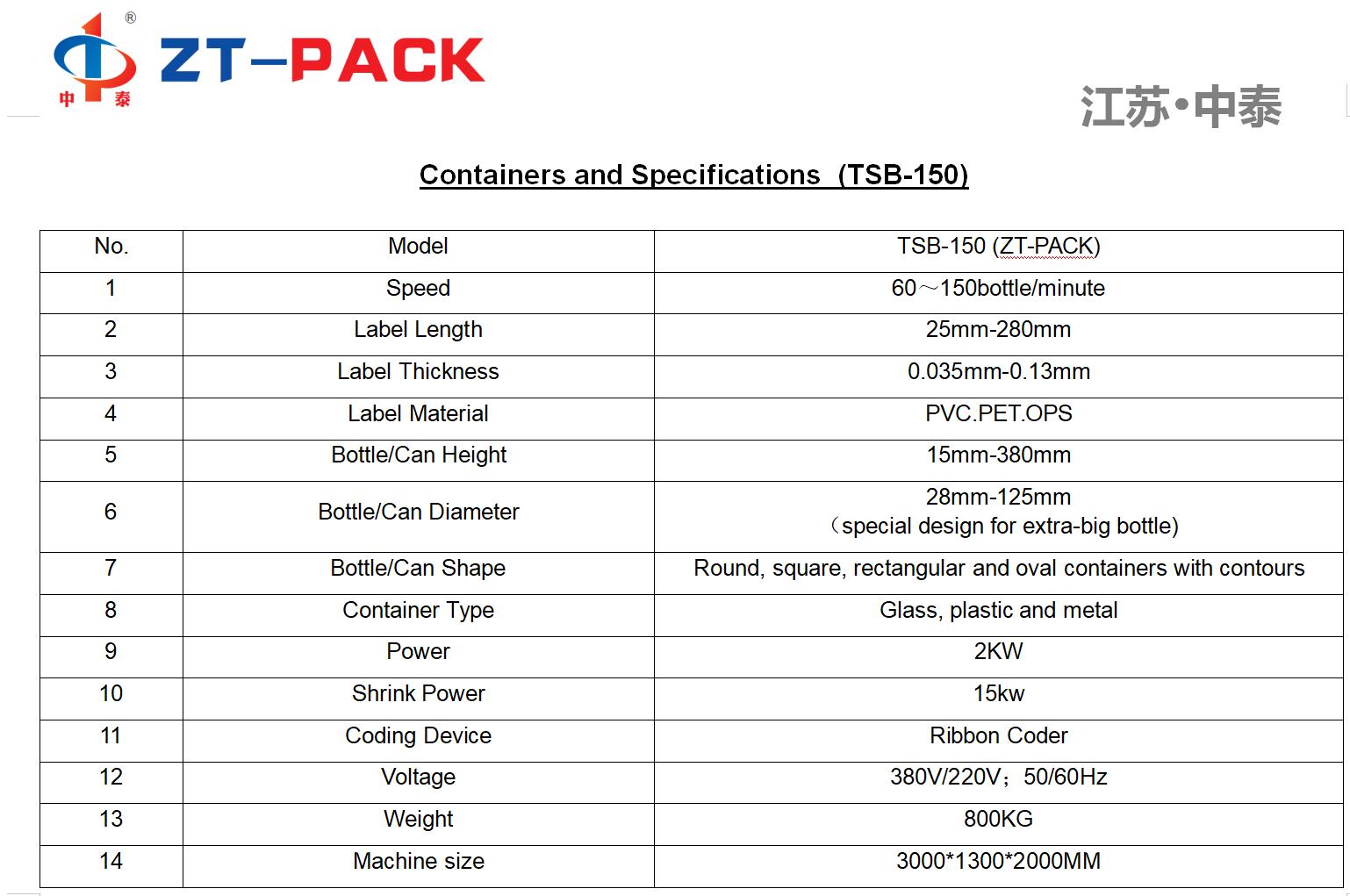

TSB-150

ZT-PACK

Machine Name : Automatic Shrink Sleeve Labeling Machine

Type: TSB-150

Double Layers Heating Tunnel

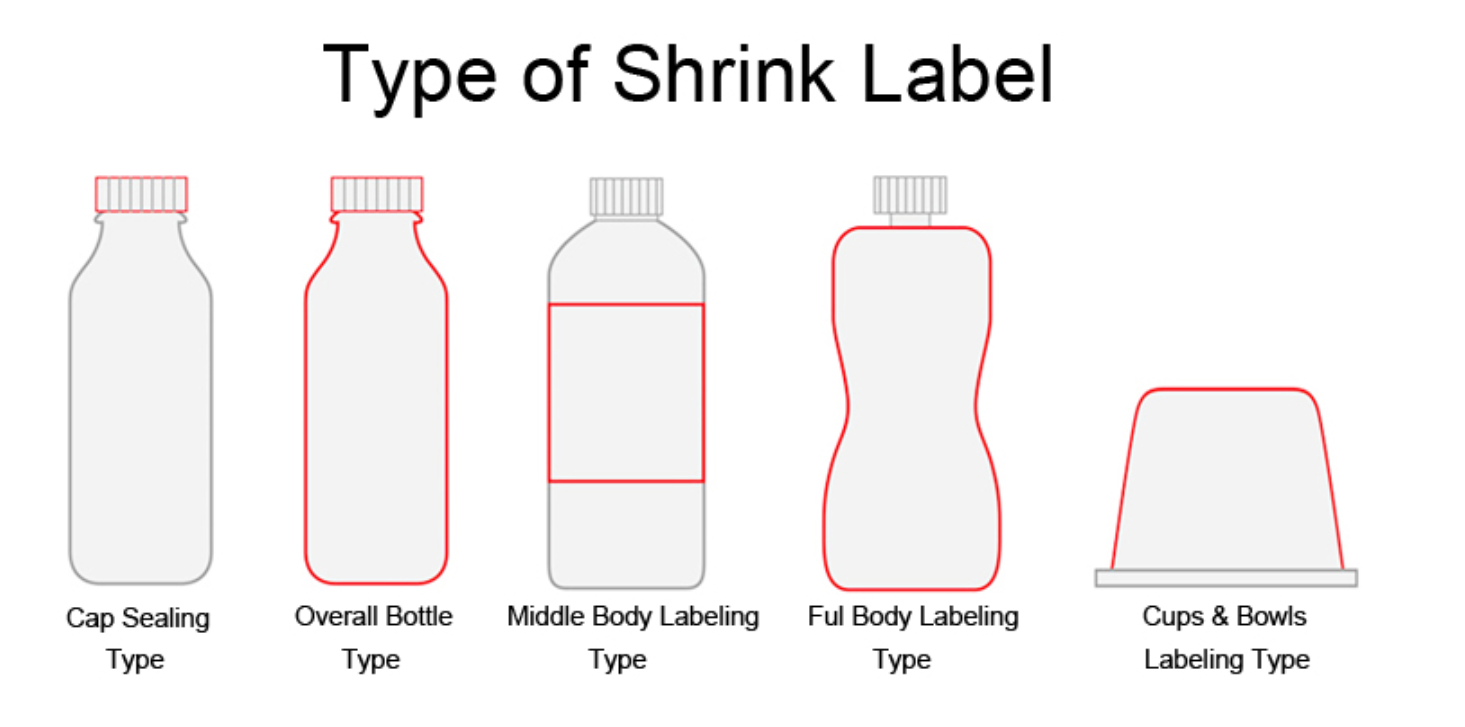

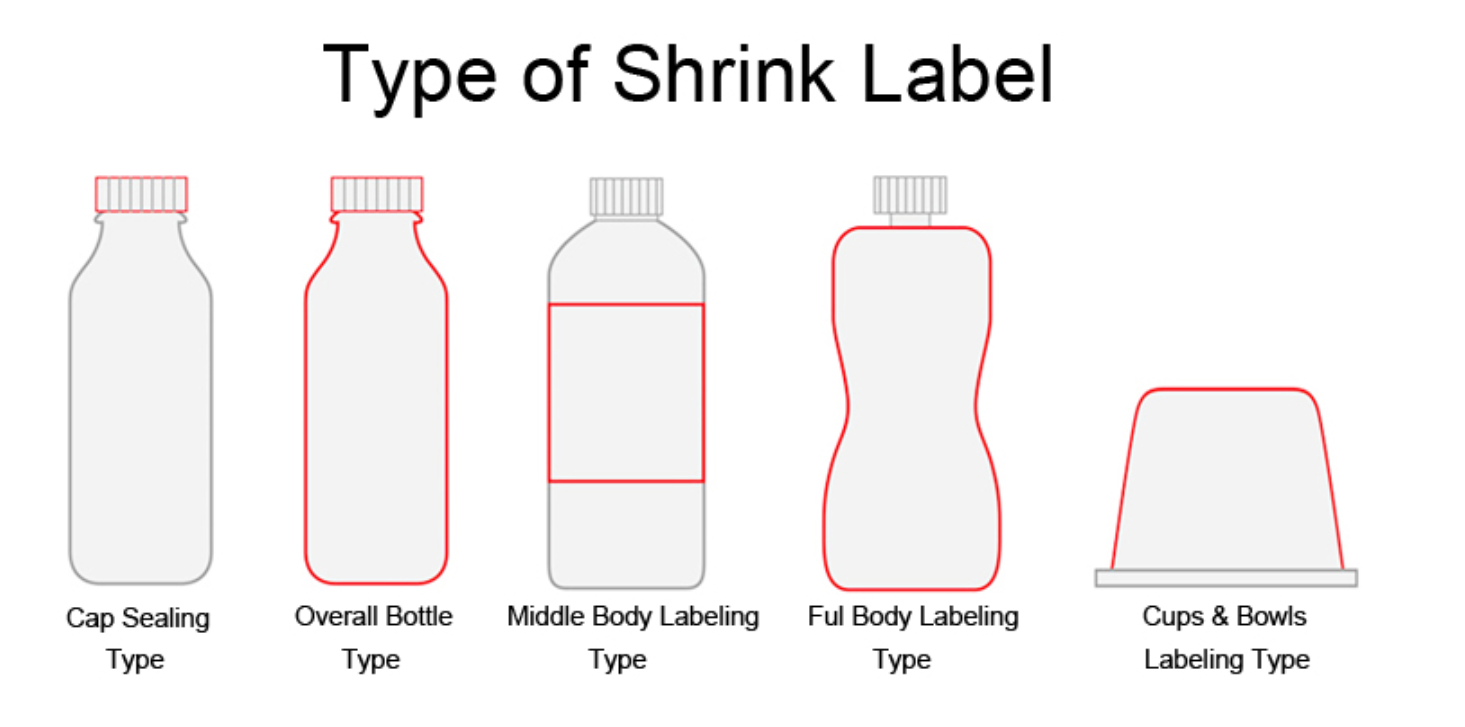

Automatic sleeve label thermal shrink packaging machine /shrink sleeve label printing machine for can,glass,bottle is suitable for various kinds of bottle types, for example: round bottles,square bottles,flat bottles, curved bottle and cup-shaped,etc.

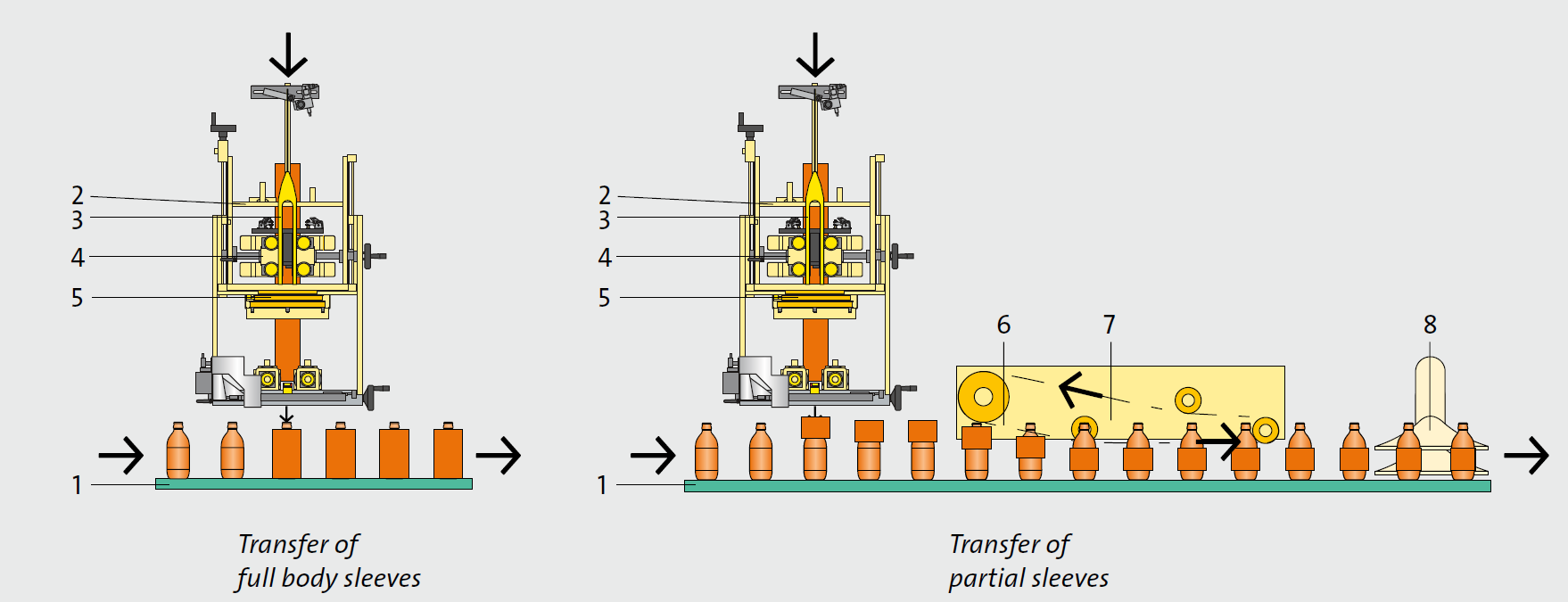

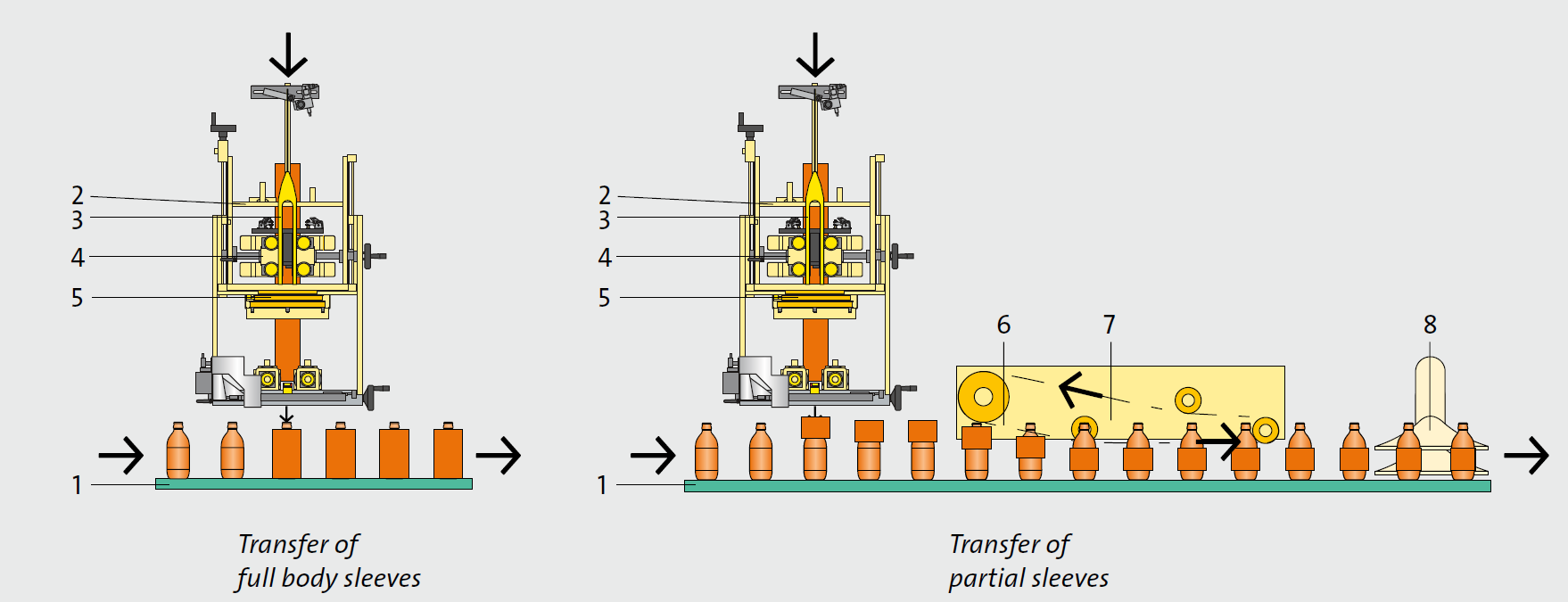

Construction :

1.Container infeed

2 .Suspension for the cutting unit (height-adjustable)

3.Mandrel

4.Sleeve transport¬unit

5 Sleeve cutter unit with servo-controlled,rotating blades

6.Lowering belt

7.Device for positioning of the sleeves (optional)

8 Hot-air nozzles for pre-shrinking (optional)Unwinding and cutting of the film sleeve is performed. After cutting, a feed applies the open sleeves directly to the container.

Depending on the container shape and the sleeve size, an optional positioning module moves the sleeve to the desired position. Partial sleeves will be moved to their exact position by means of lateral guides. Optional hot-air nozzles shrink and pre-position the sleeves. After that, the sleeves are shaped perfectly around the container contour in a steam or hot-air tunnel.

Labelling with shrinkable full body and partial sleeves

| Description | Function |

| Feeding Unit | Offer the motive of sleeve label running |

| Sleeve Label Unit | Storage sleeve label unit. |

| Main Frame Elevation Unit | Adjust the main frame height according to the bottle shape. |

| Wheeling Unit | Deal with the cutted sleeve label into the bottle |

| Blade Plate Unit | Cut off the shooting sleeve label |

| Control Unit | Control cutter operation position inside the blade plate. |

| Rear Driving Unit | Offer the driving force of sleeve label on the bullet. |

| Front Driving Unit | Clamp the bullet |

| Electric Eye Unit | Adjust the best cutting position of sleeve label |

| Bottle Detecting Unit | Adjust the sleeve label into the bottle . |

| Brush Unit | Make bottle unsleeving label into the required position. |

| Bottle Carrying Position Unit | Make the bottle stable , control the label sleeving position |

| Bullet Unit | Make the sleeve label enter and blow, convenient to drive and cut. |

| Bottle Feeding Screw | Make the bottle separate with same distance, convenient to sleeve accurately. |

Machine Description :

Shrink sleeve labeler and shrink band equipment apply and shrink middle, full body sleeve labels or tamper evident bands made from PVC, PET/PETG, OPS, or PLA on a variety of empty or filled round, square and oval containers in plastic, glass or metal. It is a perfect solution for industries including beverage, food, pharmaceutical, nutraceutical, health and beauty, consumer goods, chemical, and other manufactured goods to decorate your products. Each shrink sleeve system includes a sleeve applicator, one or two shrink tunnel modules, a steam generator and a stainless steel conveyor for transporting containers through the system. Label sleeving machine is manufactured with stainless steel, servo motor and designed with servo driven, PLC controlled label drive rollers, cutter assembly, and label shooting wheels to provide accurate and consistent shrink sleeve labeling.

This machine adopts international advanced technology, cover the circle label on the bottles. And then hot shrinking to fix on the position which bottle body designed. It is controlled by micro-computer, automatic detection and position.

Major characteristics :

1, the machine is made of stainless steel and high quality of aluminum alloy, the reasonable, intact frame, it is easy to adjust.

2, the feet bolt is not fixed, easy to move suitable for different place.

3, the shrinkable film roll with adjustable locking gear, can be adjusted according to different roll 5-10

4, the applicable bottle is the machine square bottle and round bottle

5, without tools, the driven machinery can be adjusted to meet different bottle size

6, particular inserting label ways, i.e. inserting label, it is reasonable and convenient.

7, full automatic feeder, the flat shrinking and tension are adjusted together.

8, it is assured to low error that there is inspection of rolling label cut.

9, particular blade design, blade base can be change by free, changing blade quickly and conveniently.

10, it is easy to change the central clamping device without any tools.

11, oriental rolling label device can be lifting synchronal.

12, the separating bottle screw, oriental belt and conveyor are adjusted synchronal, it is easy and quick to do.

13, adopting Schneider servo motor made in France and sensitive photo electricity, to insure the precision of cutting label.

14, stainless steel electric controller, adopting Mitsubishi PLC made in Japan

15, adopting advanced machine automatic controlling technology, main component adopts famous brand.

The machine adopts international advanced technology; cover the circle label on the pet bottle.And then hot shrinking to fix on the position which bottle body designated.This machine's structure is compact, and suitable for the production line of different direction and different height. The machinery part adopts combination designing of modularization, and makes the machine reasonable. The height adjustment adopts motor fluctuating; It is convenient to replace the material. The special cutter head designing, make the film-rolling cut more exactly and reliably.

Features:

1.The machines use the advanced man-machine interface automatic control technology,the key electric elements adopt international famous products.

2.The machine operation, easy to adjust, can be used on production line.

3.The unique design of the knife plate within the scope of the specification, shall not be in knife block, by changing the blade fast and convenient.

4.The unique set of standard methods, using the compression type of label, convenient and reasonable. 5.The whole machine transmission type structure to make changing bottle is extremely convenient.

6.Suitable for 5 ~ 10 "the membrane material, uniform, efficient, and can do, stop action.

7.Can be used in the square and round bottles.

8.the elevating center pillar height is adjusted.

9.Using high sensitivity optical fiber electric eye, precision cut length.

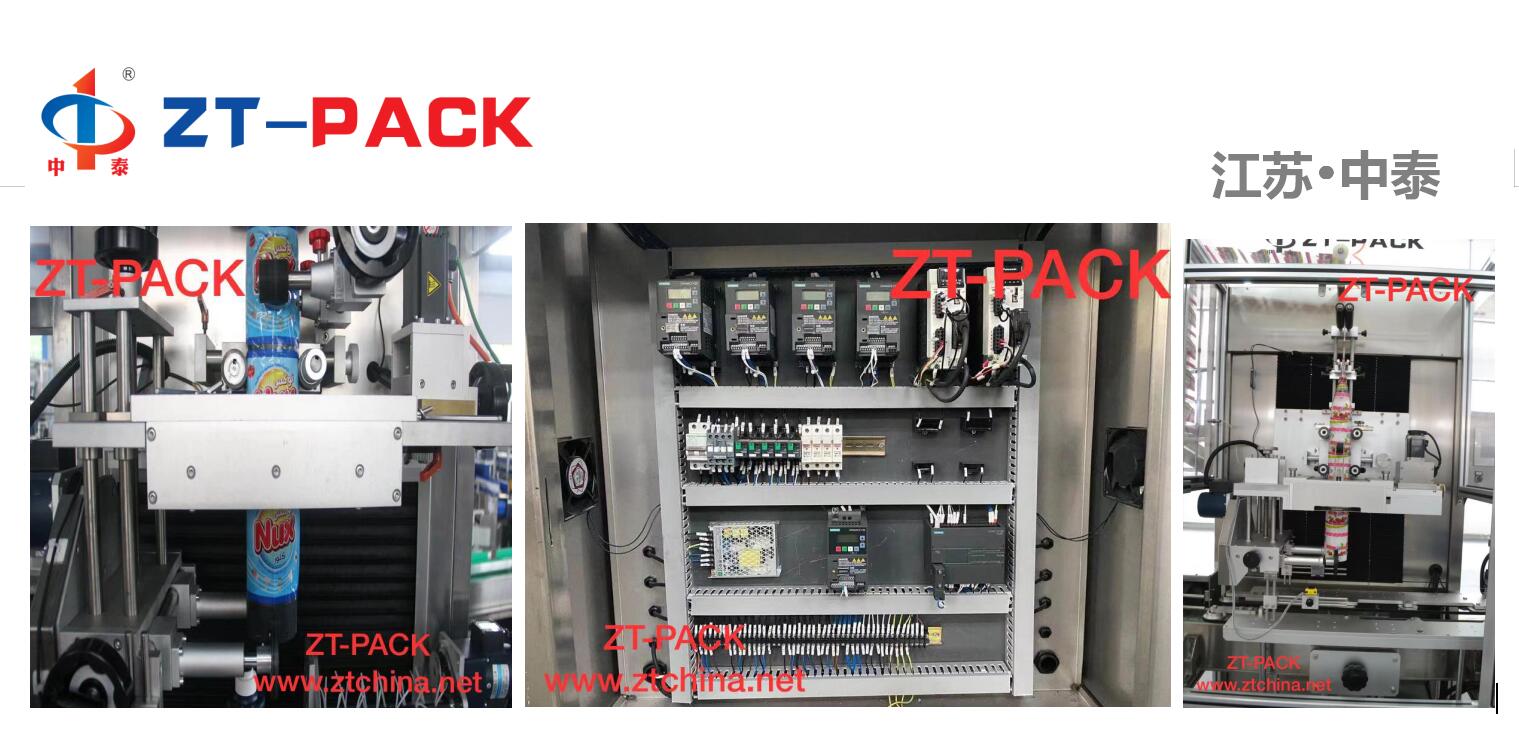

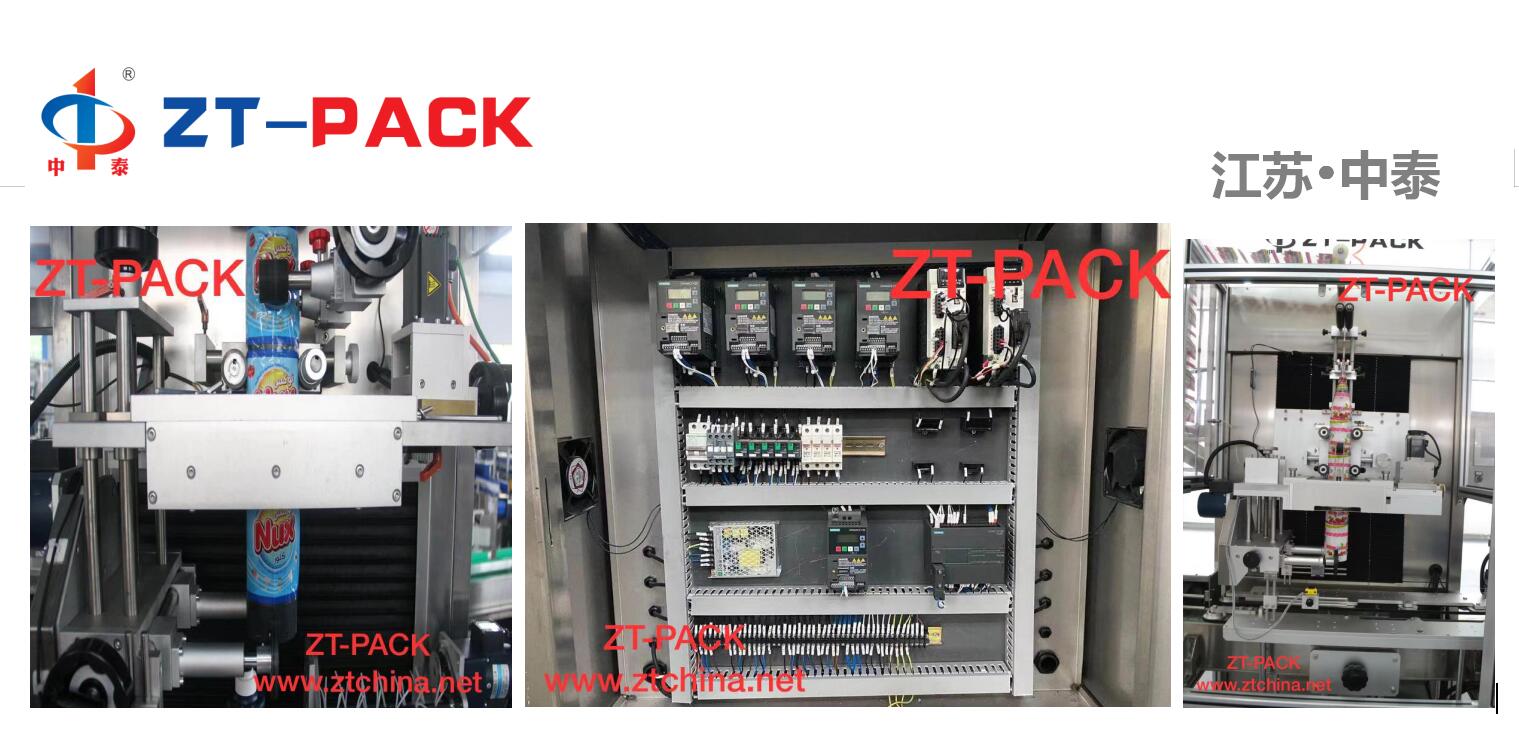

Details Pictures :

Application: PVC / PET / OPS label sleeve

* Stainless steel Main Machine Frame / Famous electrical components (SIEMENS Plc controller ,Inverter ,Mitsubishi Motor )

*Even shrink with good steam pressure control

Application : To provide steam for shrink tunnel

*Full automatic steam pressure control

*Automatic water feed system

*High quality heating tube

*water softner as optional

Application:food, beverages, mineral water and daily products.

PVC shrinkage: longitudinal shrinkage 1%-4%, transverse shrinkage 55%;

PET shrinkage: longitudinal shrinkage 1% -3%, transverse contraction 70%;

Suitable for :

Our fully automatic PVC PET label shrink machine is a high-efficiency and reliable labeling machine, specially designed for the production of labels for various industries such as beverages, food, cosmetics, and pharmaceuticals. The machine adopts advanced shrink technology, which can quickly and accurately shrink the label onto the bottle, ensuring perfect adhesion and aesthetics. At the same time, the machine also has the advantages of high automation, easy operation, and convenient maintenance, which greatly improves your production efficiency. Whether you are a small business or a large manufacturer, our fully automatic PVC PET label shrink machine can provide a stable and efficient labeling solution for your production line, helping you create more commercial value. Please contact our customer service personnel for more detailed information about this product.

Machine Name : Automatic Shrink Sleeve Labeling Machine

Type: TSB-150

Double Layers Heating Tunnel

Automatic sleeve label thermal shrink packaging machine /shrink sleeve label printing machine for can,glass,bottle is suitable for various kinds of bottle types, for example: round bottles,square bottles,flat bottles, curved bottle and cup-shaped,etc.

Construction :

1.Container infeed

2 .Suspension for the cutting unit (height-adjustable)

3.Mandrel

4.Sleeve transport¬unit

5 Sleeve cutter unit with servo-controlled,rotating blades

6.Lowering belt

7.Device for positioning of the sleeves (optional)

8 Hot-air nozzles for pre-shrinking (optional)Unwinding and cutting of the film sleeve is performed. After cutting, a feed applies the open sleeves directly to the container.

Depending on the container shape and the sleeve size, an optional positioning module moves the sleeve to the desired position. Partial sleeves will be moved to their exact position by means of lateral guides. Optional hot-air nozzles shrink and pre-position the sleeves. After that, the sleeves are shaped perfectly around the container contour in a steam or hot-air tunnel.

Labelling with shrinkable full body and partial sleeves

| Description | Function |

| Feeding Unit | Offer the motive of sleeve label running |

| Sleeve Label Unit | Storage sleeve label unit. |

| Main Frame Elevation Unit | Adjust the main frame height according to the bottle shape. |

| Wheeling Unit | Deal with the cutted sleeve label into the bottle |

| Blade Plate Unit | Cut off the shooting sleeve label |

| Control Unit | Control cutter operation position inside the blade plate. |

| Rear Driving Unit | Offer the driving force of sleeve label on the bullet. |

| Front Driving Unit | Clamp the bullet |

| Electric Eye Unit | Adjust the best cutting position of sleeve label |

| Bottle Detecting Unit | Adjust the sleeve label into the bottle . |

| Brush Unit | Make bottle unsleeving label into the required position. |

| Bottle Carrying Position Unit | Make the bottle stable , control the label sleeving position |

| Bullet Unit | Make the sleeve label enter and blow, convenient to drive and cut. |

| Bottle Feeding Screw | Make the bottle separate with same distance, convenient to sleeve accurately. |

Machine Description :

Shrink sleeve labeler and shrink band equipment apply and shrink middle, full body sleeve labels or tamper evident bands made from PVC, PET/PETG, OPS, or PLA on a variety of empty or filled round, square and oval containers in plastic, glass or metal. It is a perfect solution for industries including beverage, food, pharmaceutical, nutraceutical, health and beauty, consumer goods, chemical, and other manufactured goods to decorate your products. Each shrink sleeve system includes a sleeve applicator, one or two shrink tunnel modules, a steam generator and a stainless steel conveyor for transporting containers through the system. Label sleeving machine is manufactured with stainless steel, servo motor and designed with servo driven, PLC controlled label drive rollers, cutter assembly, and label shooting wheels to provide accurate and consistent shrink sleeve labeling.

This machine adopts international advanced technology, cover the circle label on the bottles. And then hot shrinking to fix on the position which bottle body designed. It is controlled by micro-computer, automatic detection and position.

Major characteristics :

1, the machine is made of stainless steel and high quality of aluminum alloy, the reasonable, intact frame, it is easy to adjust.

2, the feet bolt is not fixed, easy to move suitable for different place.

3, the shrinkable film roll with adjustable locking gear, can be adjusted according to different roll 5-10

4, the applicable bottle is the machine square bottle and round bottle

5, without tools, the driven machinery can be adjusted to meet different bottle size

6, particular inserting label ways, i.e. inserting label, it is reasonable and convenient.

7, full automatic feeder, the flat shrinking and tension are adjusted together.

8, it is assured to low error that there is inspection of rolling label cut.

9, particular blade design, blade base can be change by free, changing blade quickly and conveniently.

10, it is easy to change the central clamping device without any tools.

11, oriental rolling label device can be lifting synchronal.

12, the separating bottle screw, oriental belt and conveyor are adjusted synchronal, it is easy and quick to do.

13, adopting Schneider servo motor made in France and sensitive photo electricity, to insure the precision of cutting label.

14, stainless steel electric controller, adopting Mitsubishi PLC made in Japan

15, adopting advanced machine automatic controlling technology, main component adopts famous brand.

The machine adopts international advanced technology; cover the circle label on the pet bottle.And then hot shrinking to fix on the position which bottle body designated.This machine's structure is compact, and suitable for the production line of different direction and different height. The machinery part adopts combination designing of modularization, and makes the machine reasonable. The height adjustment adopts motor fluctuating; It is convenient to replace the material. The special cutter head designing, make the film-rolling cut more exactly and reliably.

Features:

1.The machines use the advanced man-machine interface automatic control technology,the key electric elements adopt international famous products.

2.The machine operation, easy to adjust, can be used on production line.

3.The unique design of the knife plate within the scope of the specification, shall not be in knife block, by changing the blade fast and convenient.

4.The unique set of standard methods, using the compression type of label, convenient and reasonable. 5.The whole machine transmission type structure to make changing bottle is extremely convenient.

6.Suitable for 5 ~ 10 "the membrane material, uniform, efficient, and can do, stop action.

7.Can be used in the square and round bottles.

8.the elevating center pillar height is adjusted.

9.Using high sensitivity optical fiber electric eye, precision cut length.

Details Pictures :

Application: PVC / PET / OPS label sleeve

* Stainless steel Main Machine Frame / Famous electrical components (SIEMENS Plc controller ,Inverter ,Mitsubishi Motor )

*Even shrink with good steam pressure control

Application : To provide steam for shrink tunnel

*Full automatic steam pressure control

*Automatic water feed system

*High quality heating tube

*water softner as optional

Application:food, beverages, mineral water and daily products.

PVC shrinkage: longitudinal shrinkage 1%-4%, transverse shrinkage 55%;

PET shrinkage: longitudinal shrinkage 1% -3%, transverse contraction 70%;

Suitable for :

Our fully automatic PVC PET label shrink machine is a high-efficiency and reliable labeling machine, specially designed for the production of labels for various industries such as beverages, food, cosmetics, and pharmaceuticals. The machine adopts advanced shrink technology, which can quickly and accurately shrink the label onto the bottle, ensuring perfect adhesion and aesthetics. At the same time, the machine also has the advantages of high automation, easy operation, and convenient maintenance, which greatly improves your production efficiency. Whether you are a small business or a large manufacturer, our fully automatic PVC PET label shrink machine can provide a stable and efficient labeling solution for your production line, helping you create more commercial value. Please contact our customer service personnel for more detailed information about this product.

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com