| Availability: | |

|---|---|

| Quantity: | |

ZT-PACK

Machine Name : 5L-30L Drum Net Weight Filling Machine Packing Line

Suitable for : Chemicals Packing

5kg -30kg drum packing

Filling System can be choosen : Net Weight Load Cell

Machine Description:

Net weigh fillers are in ideal solution for ensuring each container you fill has the same amount of product in it. They are the best for liquids filled in bulk quantities, such as 5-gallon oil , or products that have a very high value and thus need to be weighed correctly to avoid losing profit.

This is weigh type filling machine for filling 5-30 KG Liquid . Gravity filling system with weight scale under filling nozzle to assure filling accuracy.

As well as pressure tank be used to make sure the capacity speed faster.

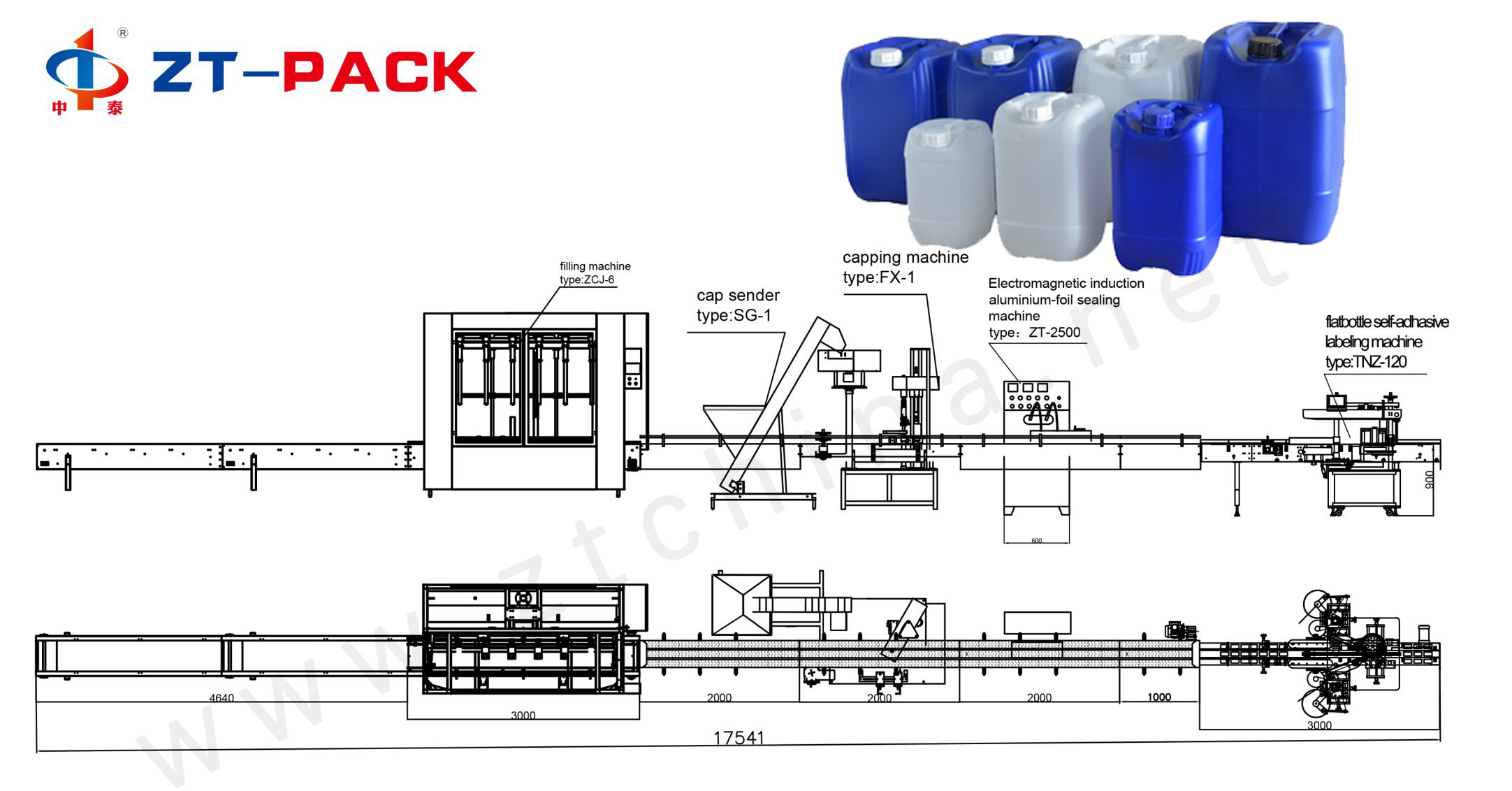

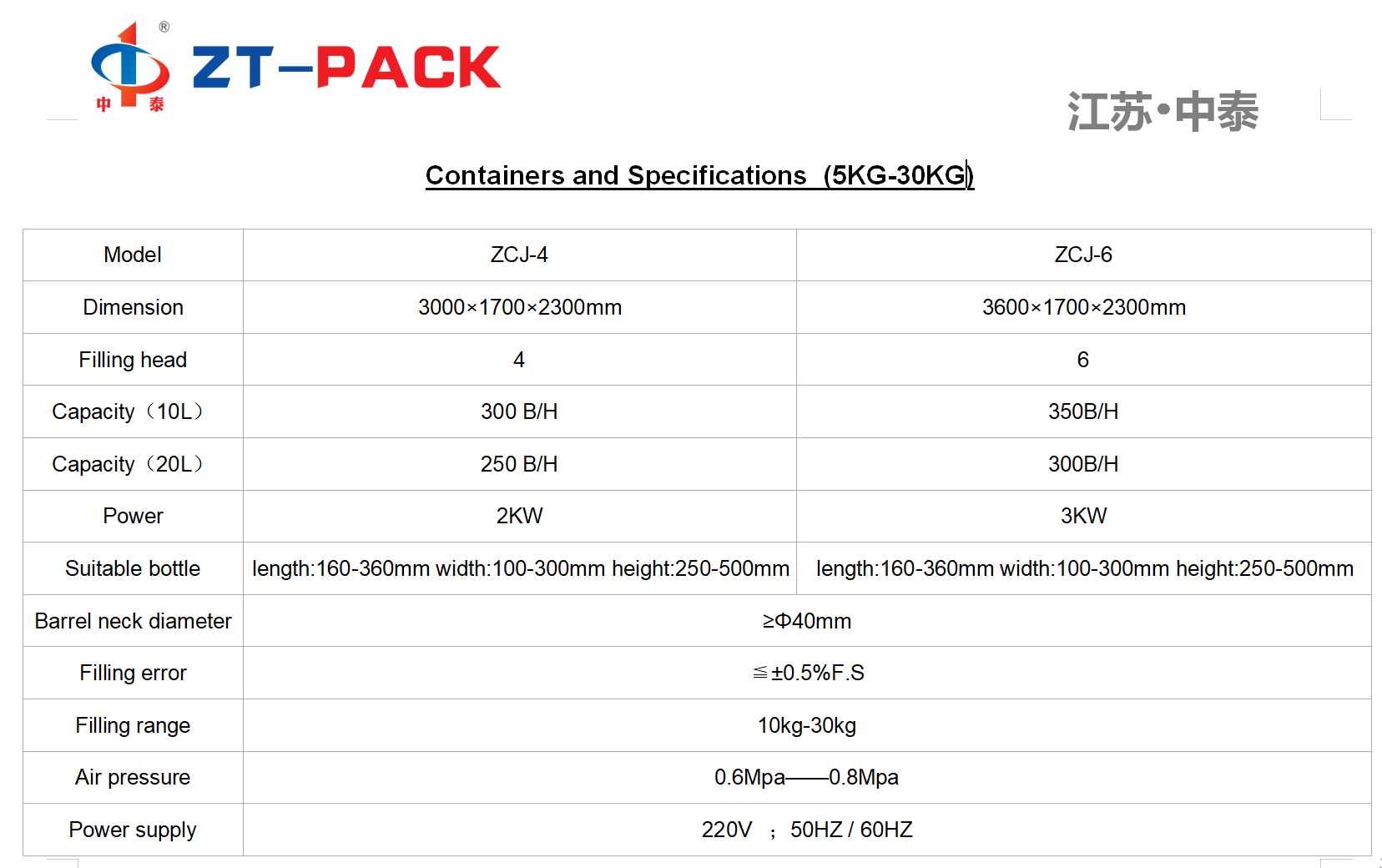

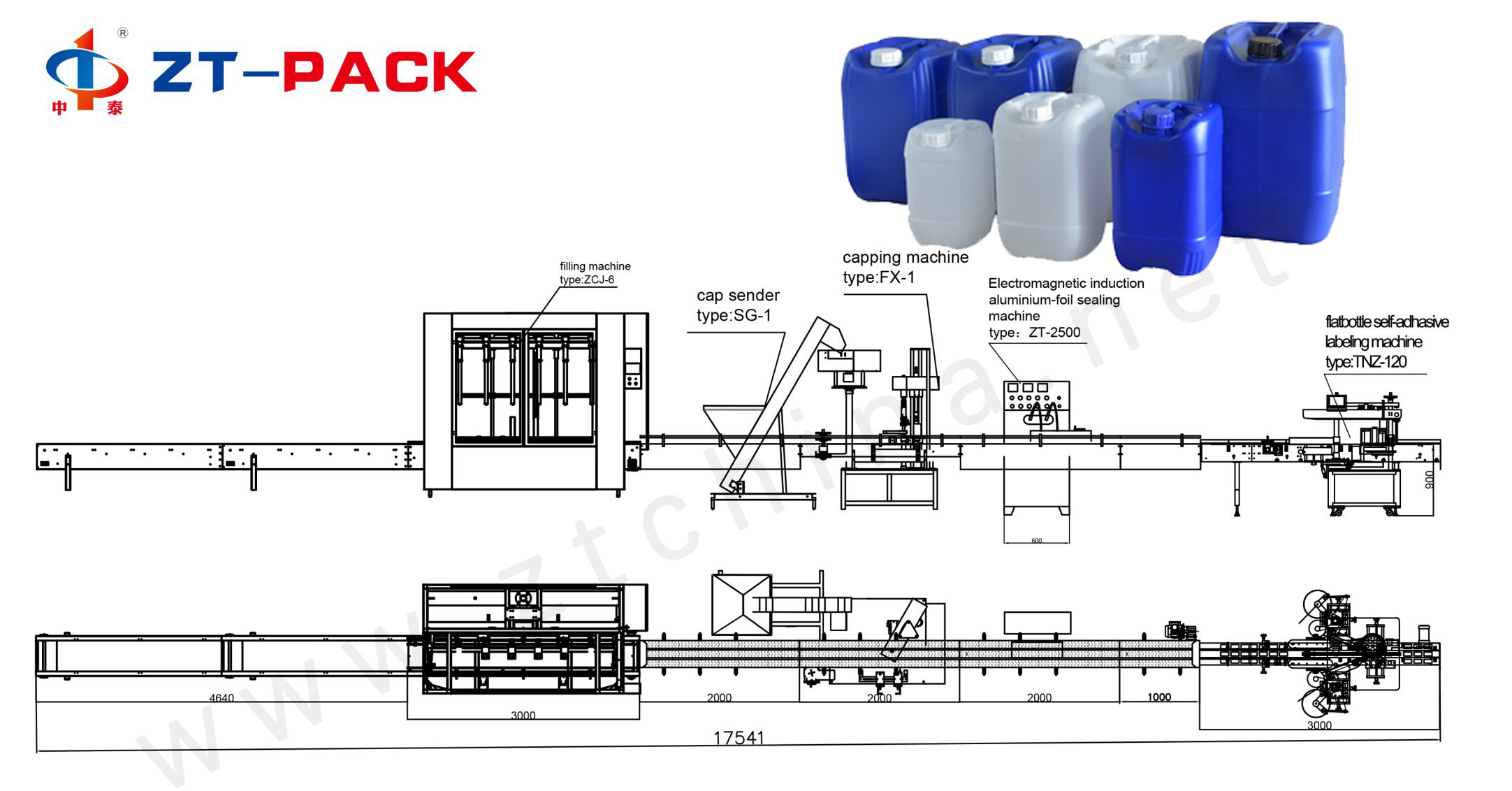

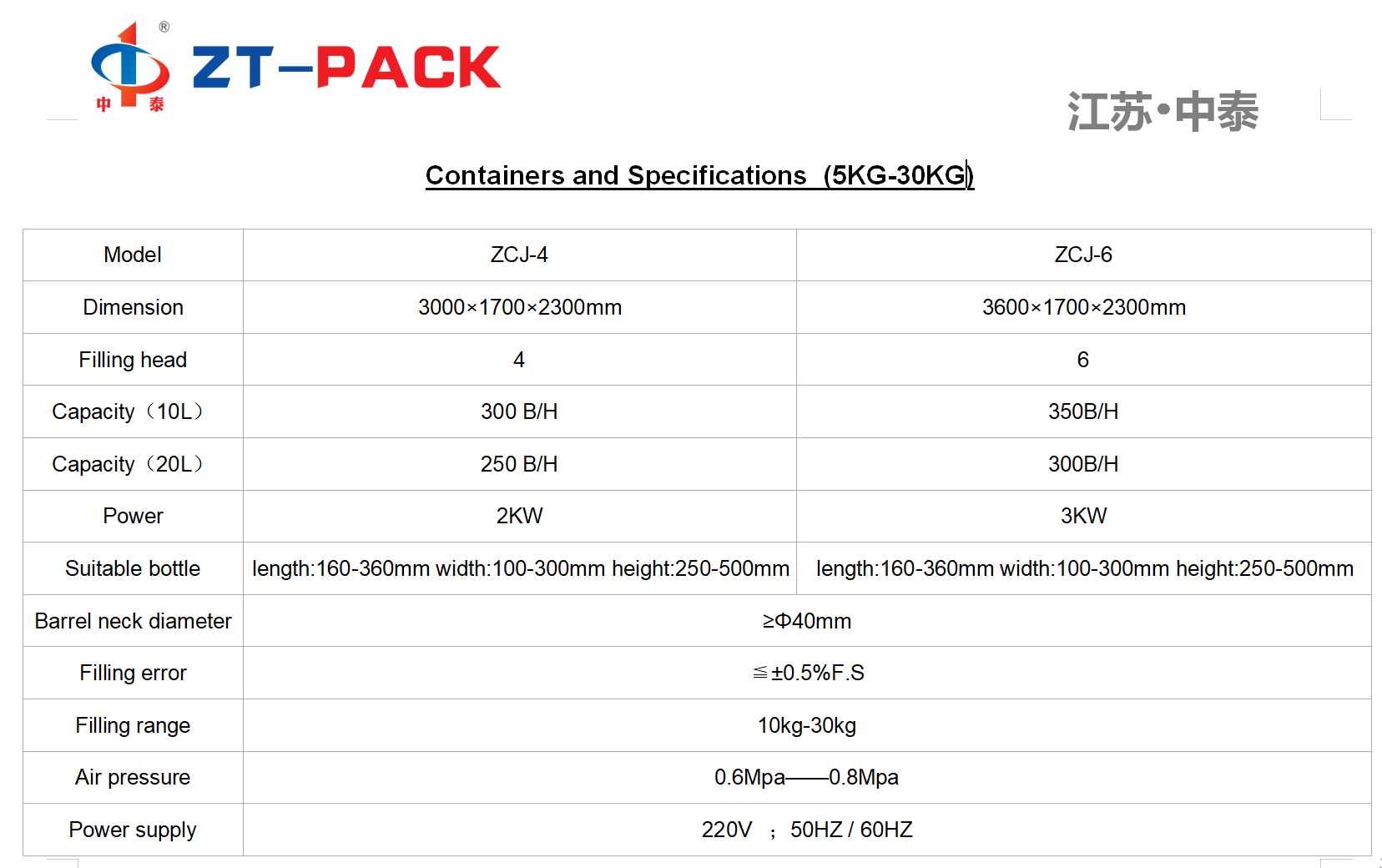

Linear type machine, can be made with 4/6 filling nozzle for different filling capacity.

It is ideal for filling big volume product like edible oil, wine, lubrication, liquid fertilizer, chemicals etc.

Net weight filler is best suited for liquids to be filled in bulk quantities e.g. 5 gallon pails, etc. or smaller quantity products that have a very high manufactured value. Oftentimes there are products that must be sold by weight for commercial reasons and therefore this filling machine is the only choice. Examples of this type of filler for bulk products include cleaning chemicals, enzyme solutions, oils and other medium value products. High value products filled by these machines include specialty adhesives and paints, precious metals dissolved in acids, and other expensive specialty chemicals.

The operation of this type of net weight drum filling machine is simple. The product bulk supply is pumped into a holding tank above a pneumatically operated valve. Cleaned containers are conveyed to the filling machine through an SS slat conveyor, positioned on individual load cell platform and tared. the valves open and real time net weight information is monitored until the target weight is achieved. The valve simply shuts when the target weight is achieved. Accuracy of fills is accomplished by various “bulk and dribble” methods in the filling process so that overfills are avoided.

The advantage of this bucket filling machine over others is that it is sometimes the only practical (and legal) type of filling for a limited range of applications and for large volume fills. It is also very accurate and effectively provides its own quality control assuming the scale is functioning properly. The disadvantage of this type of filling machine is that it is very expensive per filling head. For these reasons, the use of this filling technology is limited to the examples outlined above.

Specifications are subject to change without notice, All rights are reserved.

Heavy duty stainless steel construction

Made by high quality 304 Stainless steel, it is durable.

316 stainless steel product contact parts is available for optional according to product features.

High speed & volume production

Quick-install connecting parts , it is easy to disassemble and clear machine.

Capacity to fill a variety of container types and sizes

High accuracy fill, less product waste

Automatic bottling index kit with bottle counter

Individual fill head control

Durable construction to ensure longer life of the machine

Real time net weight monitor

Drip pan

Liquid receive tray is available in case any dripping from filling nozzle.

Diving filling head is available for filling foamy liquid.

User friendly PLC controls with touch screen HMI

Easy change over to different size bottles.

Low maintenance & operating cost

Designed with common parts for easy & quick replacement

Easy to navigate user interface

Modular design makes it easy to integrate with other bottling machines

Adaptable to fit a variety of different container styles & sizes

No bottle, No filling

Output depends on fill size,viscosity of the liquid and type of container, Available with 4/6 filling head, if you are unsure how to choose, please let us know and our professional team will give you specific advice on the best filing machine to fit your requirements.

What product to fill

What output capacity to achieve

What material and shape of containers

What size to fill

Machine Name : 5L-30L Drum Net Weight Filling Machine Packing Line

Suitable for : Chemicals Packing

5kg -30kg drum packing

Filling System can be choosen : Net Weight Load Cell

Machine Description:

Net weigh fillers are in ideal solution for ensuring each container you fill has the same amount of product in it. They are the best for liquids filled in bulk quantities, such as 5-gallon oil , or products that have a very high value and thus need to be weighed correctly to avoid losing profit.

This is weigh type filling machine for filling 5-30 KG Liquid . Gravity filling system with weight scale under filling nozzle to assure filling accuracy.

As well as pressure tank be used to make sure the capacity speed faster.

Linear type machine, can be made with 4/6 filling nozzle for different filling capacity.

It is ideal for filling big volume product like edible oil, wine, lubrication, liquid fertilizer, chemicals etc.

Net weight filler is best suited for liquids to be filled in bulk quantities e.g. 5 gallon pails, etc. or smaller quantity products that have a very high manufactured value. Oftentimes there are products that must be sold by weight for commercial reasons and therefore this filling machine is the only choice. Examples of this type of filler for bulk products include cleaning chemicals, enzyme solutions, oils and other medium value products. High value products filled by these machines include specialty adhesives and paints, precious metals dissolved in acids, and other expensive specialty chemicals.

The operation of this type of net weight drum filling machine is simple. The product bulk supply is pumped into a holding tank above a pneumatically operated valve. Cleaned containers are conveyed to the filling machine through an SS slat conveyor, positioned on individual load cell platform and tared. the valves open and real time net weight information is monitored until the target weight is achieved. The valve simply shuts when the target weight is achieved. Accuracy of fills is accomplished by various “bulk and dribble” methods in the filling process so that overfills are avoided.

The advantage of this bucket filling machine over others is that it is sometimes the only practical (and legal) type of filling for a limited range of applications and for large volume fills. It is also very accurate and effectively provides its own quality control assuming the scale is functioning properly. The disadvantage of this type of filling machine is that it is very expensive per filling head. For these reasons, the use of this filling technology is limited to the examples outlined above.

Specifications are subject to change without notice, All rights are reserved.

Heavy duty stainless steel construction

Made by high quality 304 Stainless steel, it is durable.

316 stainless steel product contact parts is available for optional according to product features.

High speed & volume production

Quick-install connecting parts , it is easy to disassemble and clear machine.

Capacity to fill a variety of container types and sizes

High accuracy fill, less product waste

Automatic bottling index kit with bottle counter

Individual fill head control

Durable construction to ensure longer life of the machine

Real time net weight monitor

Drip pan

Liquid receive tray is available in case any dripping from filling nozzle.

Diving filling head is available for filling foamy liquid.

User friendly PLC controls with touch screen HMI

Easy change over to different size bottles.

Low maintenance & operating cost

Designed with common parts for easy & quick replacement

Easy to navigate user interface

Modular design makes it easy to integrate with other bottling machines

Adaptable to fit a variety of different container styles & sizes

No bottle, No filling

Output depends on fill size,viscosity of the liquid and type of container, Available with 4/6 filling head, if you are unsure how to choose, please let us know and our professional team will give you specific advice on the best filing machine to fit your requirements.

What product to fill

What output capacity to achieve

What material and shape of containers

What size to fill

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com