| Availability: | |

|---|---|

| Quantity: | |

ZT-PACK

Machine Name : Disinfectant Antiseptic Glass Cleaner Watery Foamy Liquids Filling Machine Packing Line

1: Suitable For Filling :

Glass Cleaner / Disinfectant / Multi Purpose Cleaner / Alcohol Liquid / Mouthwash / Air Freshener / Antiseptic ...Etc low viscous kinds Products

For Foamy and High Foamy Product : Diving system + Foamy Sucking System

2: Filling System : Gravity Type

3: Accuracy : 1%

4: Bottle Type : Plastic Jerry Tin Can

5: Bottle Shape : Round & Flat

6: Bottle Size : 50ml -5000ml

( According to bottle size , filling nozzles may need change )

9: Packing Line Included :

Product description:

this is the line for low viscous no corrosive liquids filling packing line

This is Gravity Type Time Control Filling Machine Suitable For :This gravity-based time-controlled filling machine is perfect for low viscosity and density liquids such as caustic soda, preservatives, glass cleaners, and more. It is specifically designed for low viscosity, foam and non-foam liquids, and even foam solutions. With its diving system and foam suction system, it ensures faster filling speeds and consistent liquid levels. This filling machine is suitable for 50ml to 5000ml liquid filling of low viscosity products. Trust our Disinfectant Antiseptic Glass Cleaner Liquids Filling Machine Packing Line to streamline your production process and increase efficiency.

Main configuration:

Intelligent bottle unscrambler, intelligent filling and capping integrated machine, online checkweighing and rejecting device, aluminum foil sealing machine, inkjet printer, two-dimensional code traceability system, high-speed unpacking machine, partition machine, intelligent packing machine, online inspection Heavy rejection machine, intelligent stacker, robot palletizer.

main feature:

1. This production line is suitable for packaging pesticides, lubricants, food-grade oils, sauces, seasonings, alcoholic beverages, paints, personal care products such as hair conditioner and body wash, disinfectants, and detergents.

2. The entire line can be operated by 2-3 people, reducing labor intensity and labor costs.

3. The filling speed of the production line ranges from 1000 to 6000 bottles per hour and can be customized according to specific requirements.

4. The average filling accuracy is ±0.2%, ensuring precision and minimizing unnecessary waste.

5. The production line is made of stainless steel, which not only looks aesthetically pleasing but also has a high quality appearance. Customers are welcome to visit the production line.

Suitable for Fill :

Related Machines :

Machines Included :

LP-200 Automatic Bottle Unscrambler

Applicable container: φ45-95mm

H80-230mm

Dimensions: 2900X1500X1300 (LXWXH)

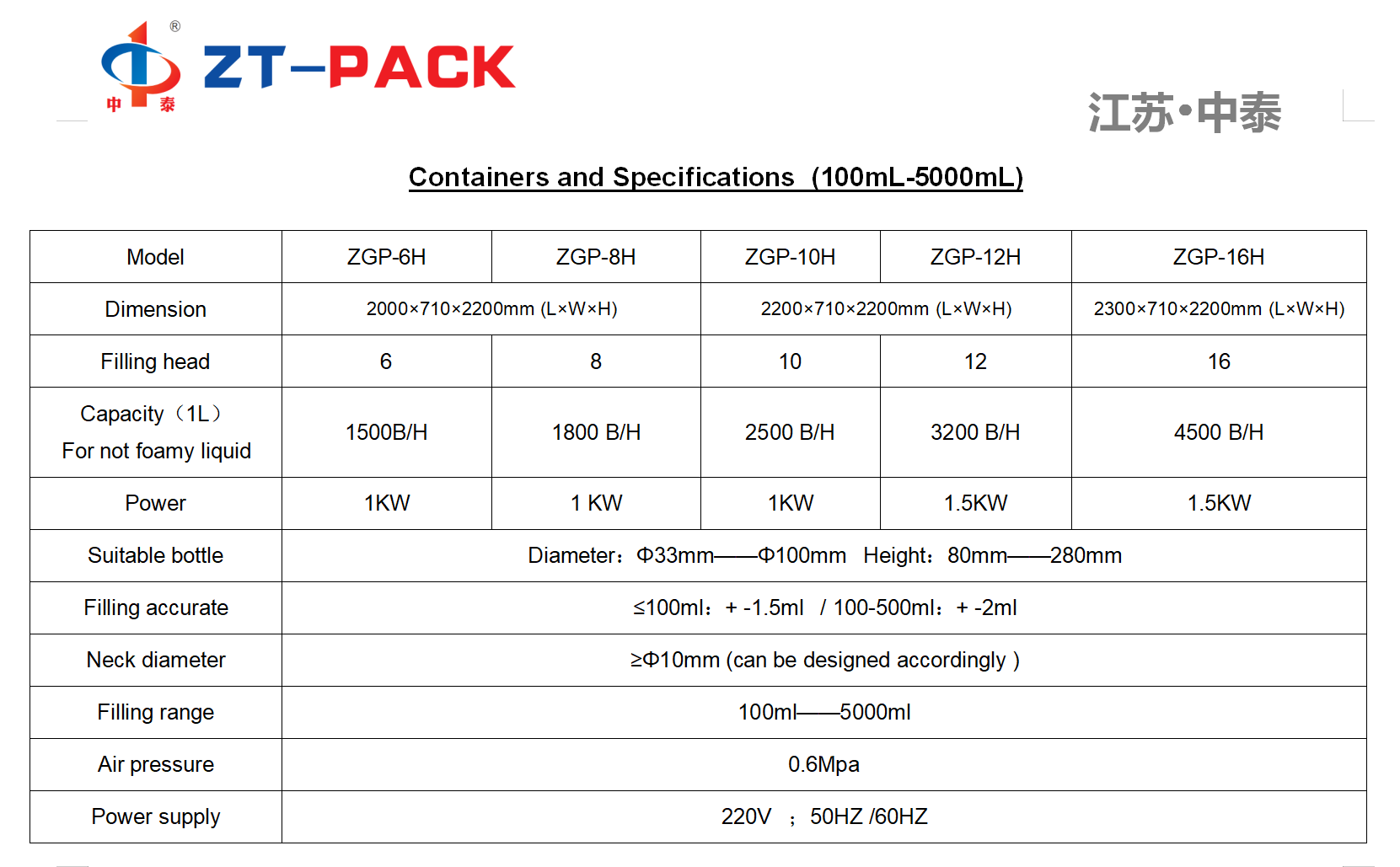

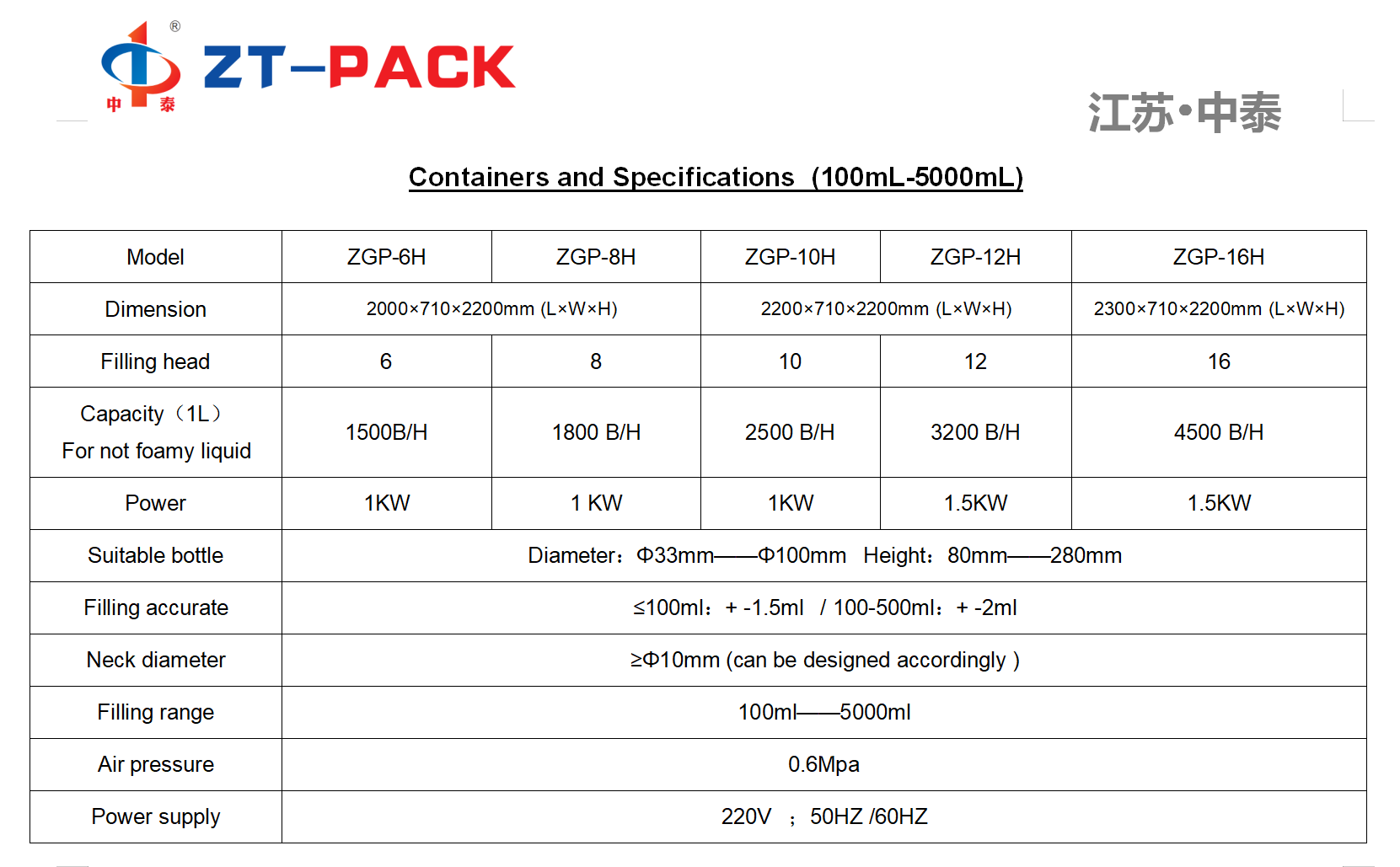

ZGP-H Linear Gravity Filling Machine

Filling container: 50-5000ml

Measurement accuracy: 200ml, ±1%; 200-1000ml, ±0.5%

Applicable bottle type: round bottle: φ40-95mm, height 80-230mm

Square bottle: length and width 40-95mm, height 80-230mm

Dimensions: 2435X1560X2200 (LXWXH)

FXZ-160A Linear Capping Machine

Applicable bottle type: φ40-90mm, H80-230mm

Bottle cap specification: φ30-70mm

Dimensions: 2100X1490X2200mm (LXWXH)

TNZ-120 Automatic self-adhesive labeling machine

Applicable bottle type: φ40-95mm, H80-250mm

Label size: H20-140mm L50-320mm

Dimensions: 2440X1200X1800 (LXWLH)

Automatic case packing machine

Material size: φ45-95mm

Carton size: L250-500mm, W200-300mm, H100-280mm

Dimensions: 2240X2250X2780mm (LXWXH)

Key Features :

Heavy-duty stainless steel constructed

Stainless steel Reservoir

Automatic Bottling Index kit with bottle counter

Pneumatic indexing gates (count in, count out)

Automatic product level sensing float system

Easily adjustable nozzle height settings accommodate vials to gallons

User friendly PLC controls with touch screen HMI

No bottle/No fill sensor

Bottle backup sensor (downstream) delays operation until jam is cleared

Able to output multiple doses per container for large containers

Easy clean stainless steel quick connect fittings

Drip Tray

Diving heads nozzles for bottom up filling to reduce foam

Neck grabbers for containers with small opening

Specifications are subject to change without notice, All rights are reserved.

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

Machine Name : Disinfectant Antiseptic Glass Cleaner Watery Foamy Liquids Filling Machine Packing Line

1: Suitable For Filling :

Glass Cleaner / Disinfectant / Multi Purpose Cleaner / Alcohol Liquid / Mouthwash / Air Freshener / Antiseptic ...Etc low viscous kinds Products

For Foamy and High Foamy Product : Diving system + Foamy Sucking System

2: Filling System : Gravity Type

3: Accuracy : 1%

4: Bottle Type : Plastic Jerry Tin Can

5: Bottle Shape : Round & Flat

6: Bottle Size : 50ml -5000ml

( According to bottle size , filling nozzles may need change )

9: Packing Line Included :

Product description:

this is the line for low viscous no corrosive liquids filling packing line

This is Gravity Type Time Control Filling Machine Suitable For :This gravity-based time-controlled filling machine is perfect for low viscosity and density liquids such as caustic soda, preservatives, glass cleaners, and more. It is specifically designed for low viscosity, foam and non-foam liquids, and even foam solutions. With its diving system and foam suction system, it ensures faster filling speeds and consistent liquid levels. This filling machine is suitable for 50ml to 5000ml liquid filling of low viscosity products. Trust our Disinfectant Antiseptic Glass Cleaner Liquids Filling Machine Packing Line to streamline your production process and increase efficiency.

Main configuration:

Intelligent bottle unscrambler, intelligent filling and capping integrated machine, online checkweighing and rejecting device, aluminum foil sealing machine, inkjet printer, two-dimensional code traceability system, high-speed unpacking machine, partition machine, intelligent packing machine, online inspection Heavy rejection machine, intelligent stacker, robot palletizer.

main feature:

1. This production line is suitable for packaging pesticides, lubricants, food-grade oils, sauces, seasonings, alcoholic beverages, paints, personal care products such as hair conditioner and body wash, disinfectants, and detergents.

2. The entire line can be operated by 2-3 people, reducing labor intensity and labor costs.

3. The filling speed of the production line ranges from 1000 to 6000 bottles per hour and can be customized according to specific requirements.

4. The average filling accuracy is ±0.2%, ensuring precision and minimizing unnecessary waste.

5. The production line is made of stainless steel, which not only looks aesthetically pleasing but also has a high quality appearance. Customers are welcome to visit the production line.

Suitable for Fill :

Related Machines :

Machines Included :

LP-200 Automatic Bottle Unscrambler

Applicable container: φ45-95mm

H80-230mm

Dimensions: 2900X1500X1300 (LXWXH)

ZGP-H Linear Gravity Filling Machine

Filling container: 50-5000ml

Measurement accuracy: 200ml, ±1%; 200-1000ml, ±0.5%

Applicable bottle type: round bottle: φ40-95mm, height 80-230mm

Square bottle: length and width 40-95mm, height 80-230mm

Dimensions: 2435X1560X2200 (LXWXH)

FXZ-160A Linear Capping Machine

Applicable bottle type: φ40-90mm, H80-230mm

Bottle cap specification: φ30-70mm

Dimensions: 2100X1490X2200mm (LXWXH)

TNZ-120 Automatic self-adhesive labeling machine

Applicable bottle type: φ40-95mm, H80-250mm

Label size: H20-140mm L50-320mm

Dimensions: 2440X1200X1800 (LXWLH)

Automatic case packing machine

Material size: φ45-95mm

Carton size: L250-500mm, W200-300mm, H100-280mm

Dimensions: 2240X2250X2780mm (LXWXH)

Key Features :

Heavy-duty stainless steel constructed

Stainless steel Reservoir

Automatic Bottling Index kit with bottle counter

Pneumatic indexing gates (count in, count out)

Automatic product level sensing float system

Easily adjustable nozzle height settings accommodate vials to gallons

User friendly PLC controls with touch screen HMI

No bottle/No fill sensor

Bottle backup sensor (downstream) delays operation until jam is cleared

Able to output multiple doses per container for large containers

Easy clean stainless steel quick connect fittings

Drip Tray

Diving heads nozzles for bottom up filling to reduce foam

Neck grabbers for containers with small opening

Specifications are subject to change without notice, All rights are reserved.

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com