2: Filling System : Piston

3: Bottle Type : Plastic Jerry Tin Can

4: Accuracy : 0.2% (piston type)

5: Filling Range : 50ml -1000ml

6: Bottle Shape : Round & Flat

7: Bottle Material : Plastic & Glass & Metal

| Availability: | |

|---|---|

| Quantity: | |

ZT-PACK

Machine Name :

100ml -1000ml Full Automatic Edible Oil Filling Machine Packing Line

Ideal For Oil Filling Packing :

5: Filling Range : 50ml -1000ml

6: Bottle Shape : Round & Flat

7: Bottle Material : Plastic & Glass & Metal

Suitable for fill : Edible Oil / Cooking OIl / Sunflower Oil / Oil kinds Products

Filling Range : 50ml -1000ml

Speed can be choosen : from 1000BPH-6000BPH (basic on 1L )

Product description:

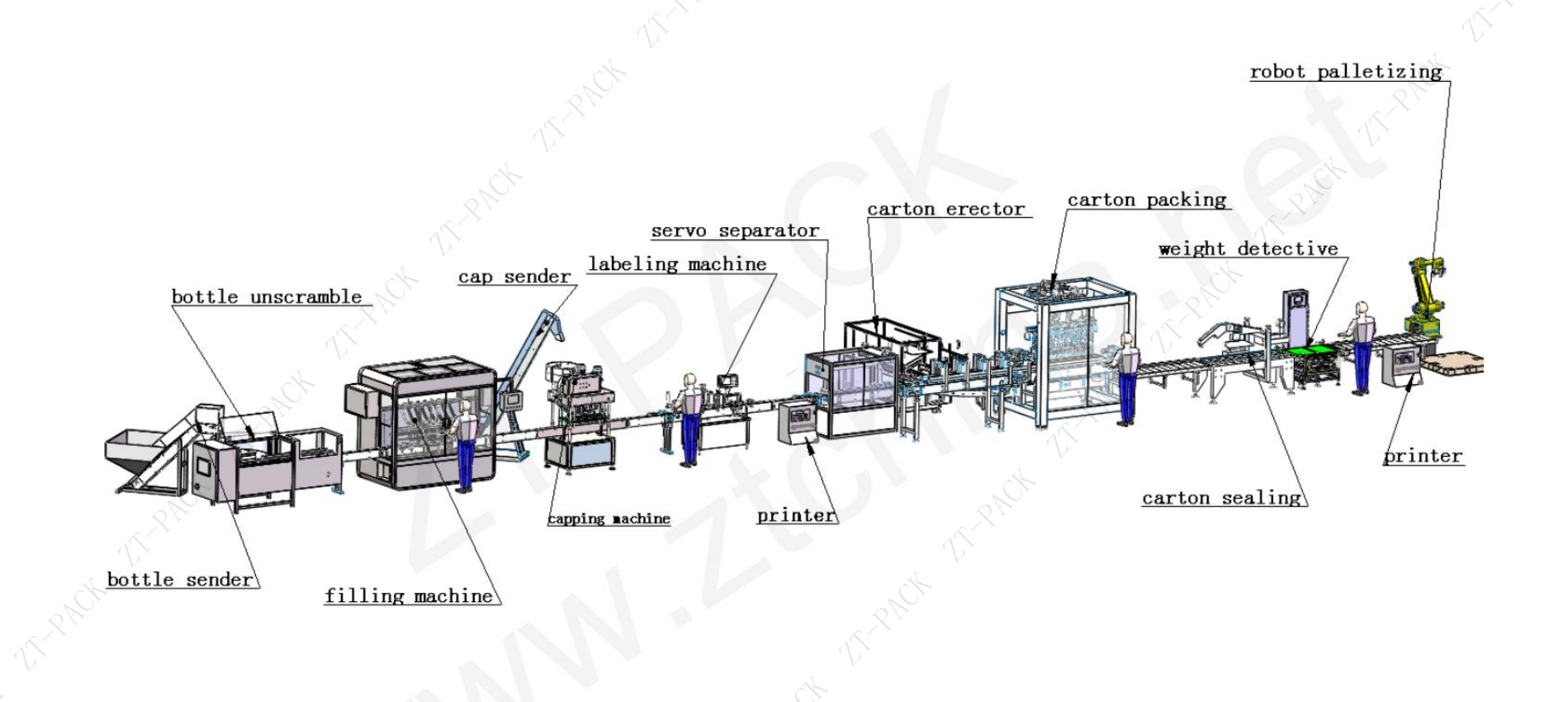

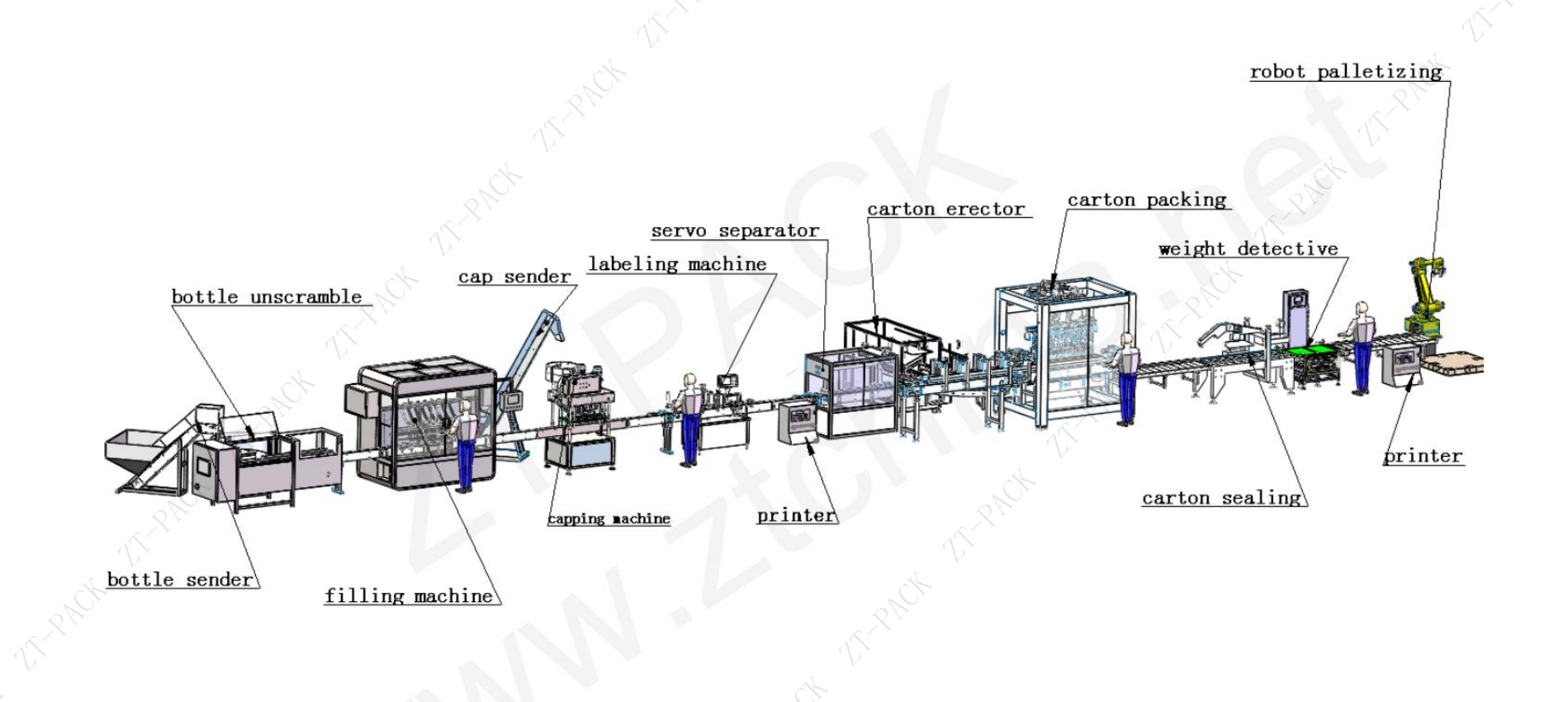

This Production Packing Line Suitable for Oils Filling , capping , labeling , date printer , carton packing machine , palletilizer

with high accuracy and suitable for different sizes and shapes of bottles without change parts

Automatically complete bottle unscramble, filling, capping, sealing, labeling, QR code, unpacking, packing, sealing, and palletizing, equipped with an integrated environmental protection cover. It conforms to the standards of safety, environmental protection and intelligent three-levelization, and the production process is automatically coordinated, which is stable and efficient.

In the fields of edible oil, food, etc., the filling production line adapts to different materials, bottle types, output, scenarios, etc. Design the corresponding filling production line. ZT-PACK starts from the needs of customers and provides fully automatic filling production lines. Automatic filling uses piston cylinder, servo motor, magnetic pump, rotor pump, weighing sensor, etc. as the material transmission system.

Suitable for Packing :

As shown in the pictures new cylinder liner in the piston bottom will be much more fexible than the unable disassembled and washed traditional cylinder, you can see touch screen and separate piston and cylinder liner, in order to easier cleaning for residual materials, easy choose different mode for different material or color.

1.widely used in filling machinery,especially suitable for filling viscous material.

2.Fast filling speed, prevision and stability

3.Delicate and small,esay for arrangement of pipe arrangement

4.special seal design at the bottom of the filling nozzle, filling without dripping

5.chamfering structure on the bottom of filling head, with orientation effect and submersible filling

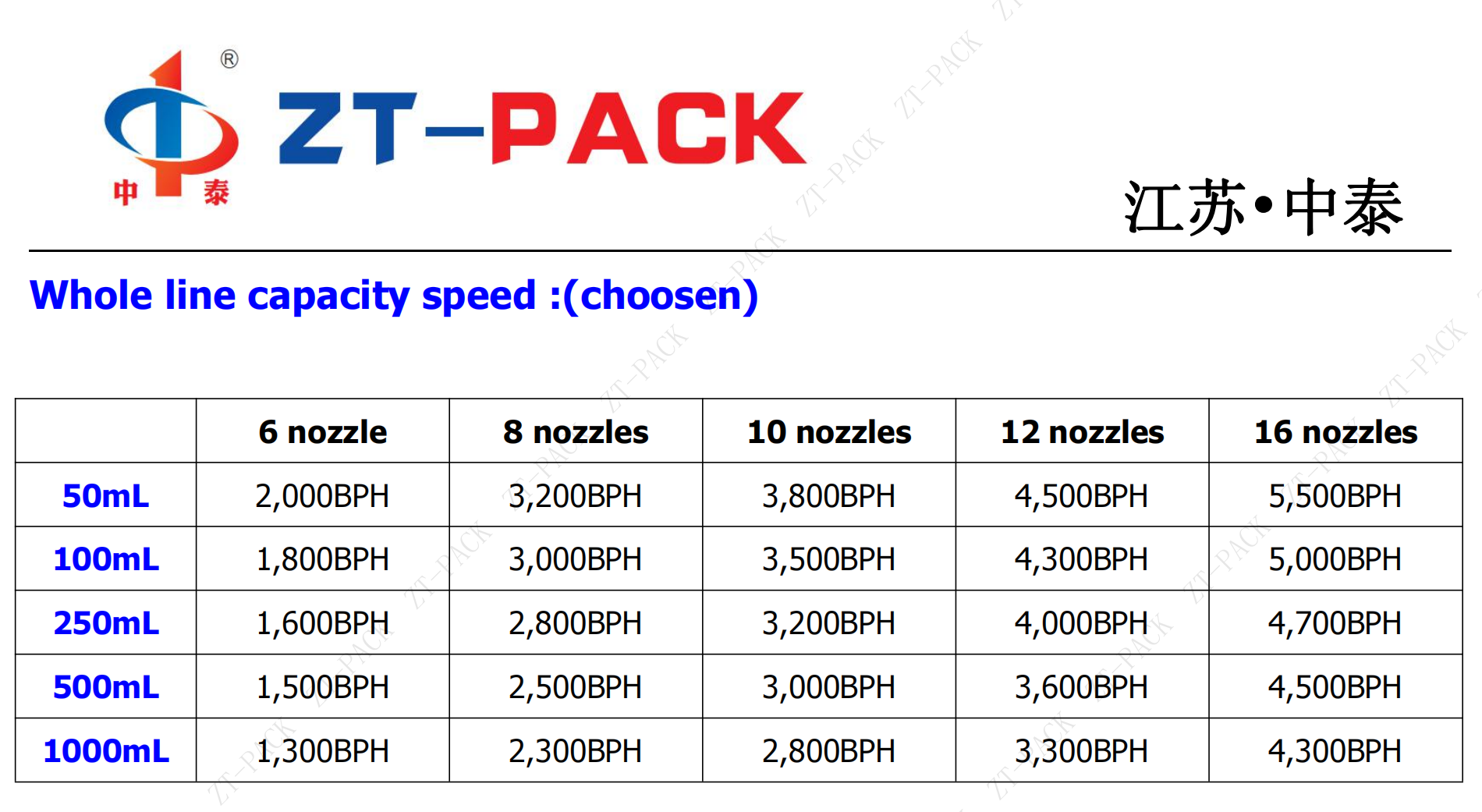

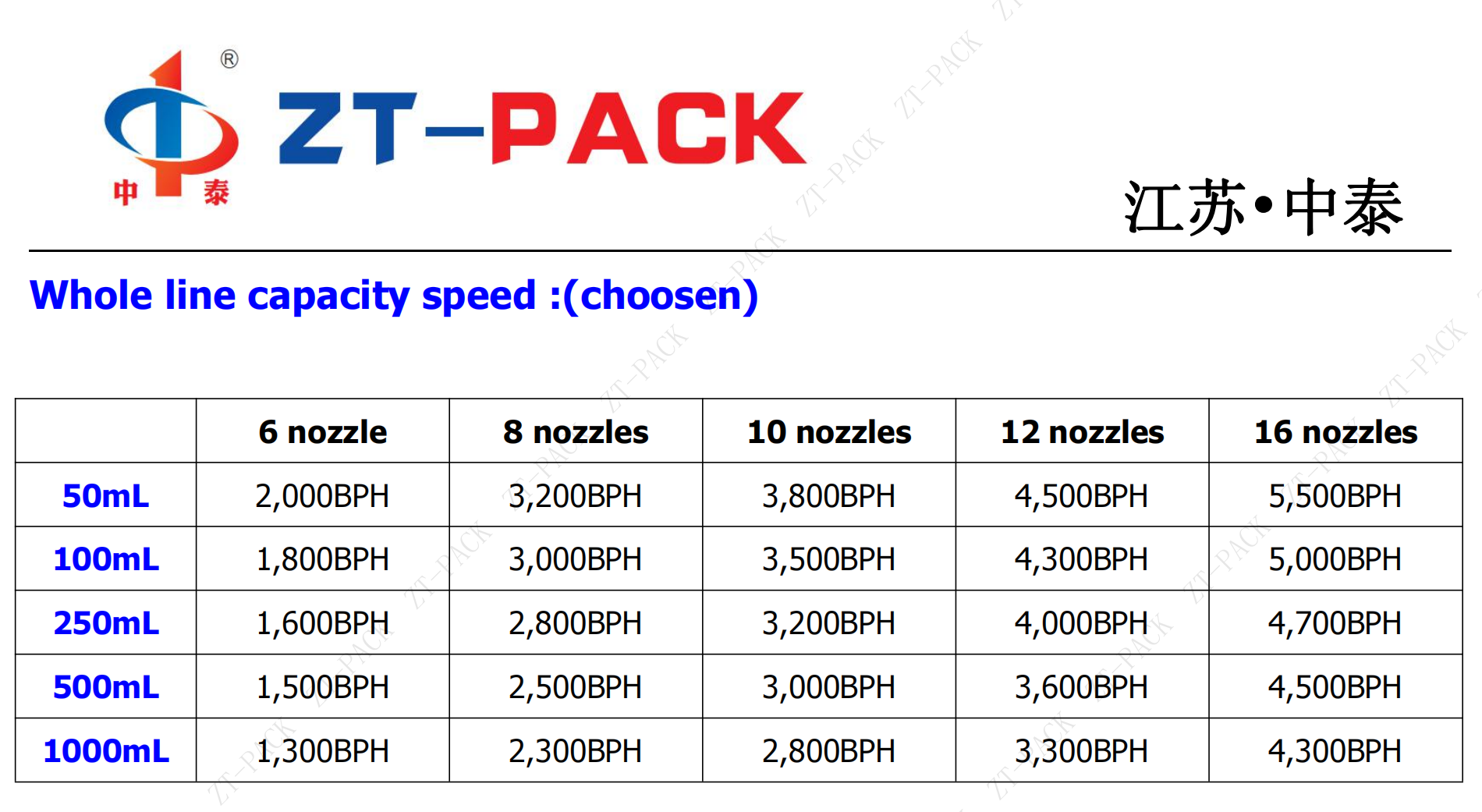

Capacity Speed Choose :

Key Features :

Heavy-duty stainless steel constructed

Stainless steel Reservoir

Automatic Bottling Index kit with bottle counter

Pneumatic indexing gates (count in, count out)

Automatic product level sensing float system

Easily adjustable nozzle height settings accommodate vials to gallons

User friendly PLC controls with touch screen HMI

No bottle/No fill sensor

Bottle backup sensor (downstream) delays operation until jam is cleared

Able to output multiple doses per container for large containers

Easy clean stainless steel quick connect fittings

Drip Tray

Diving heads nozzles for bottom up filling to reduce foam

Neck grabbers for containers with small opening

Specifications are subject to change without notice, All rights are reserved.

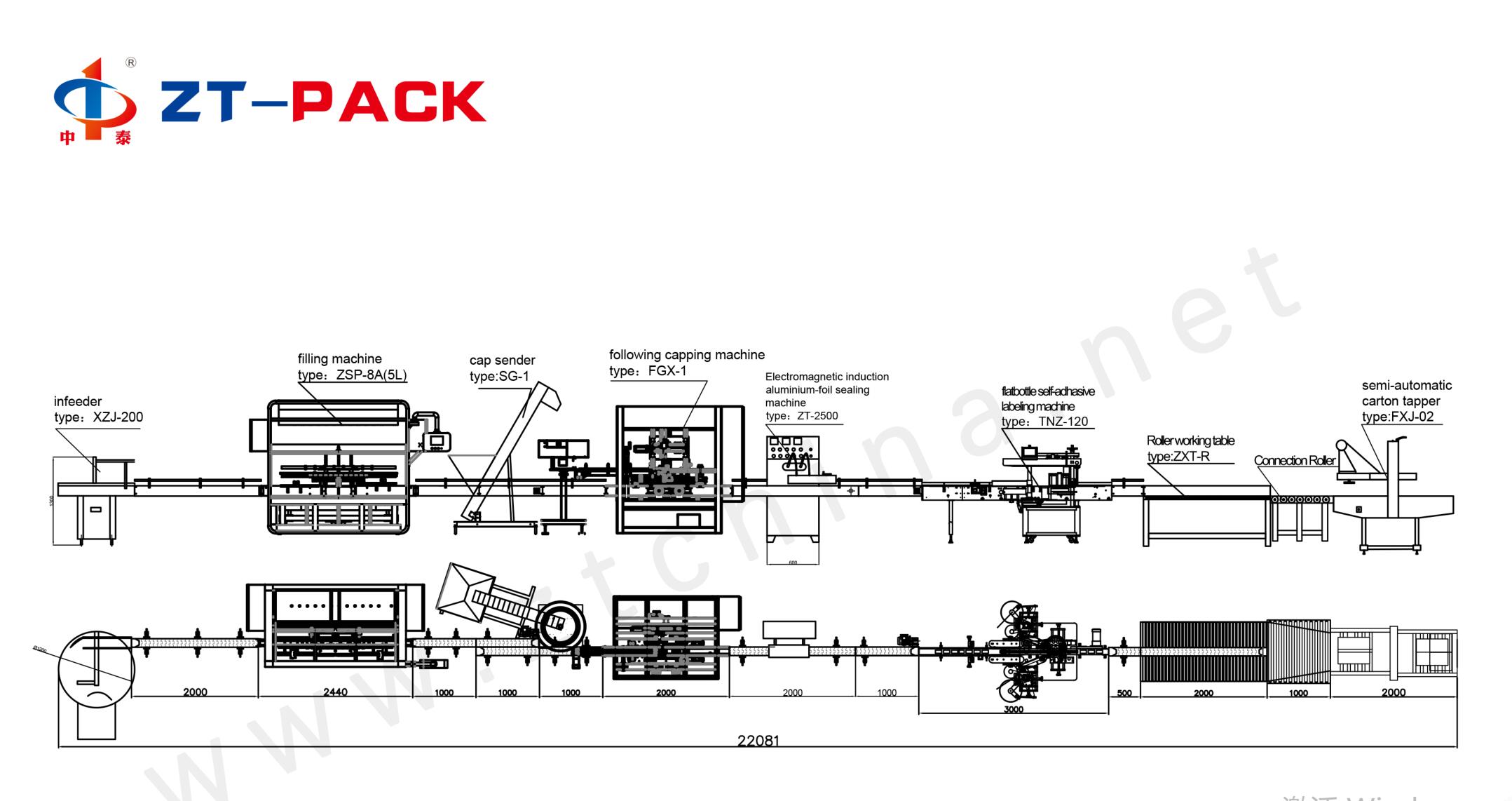

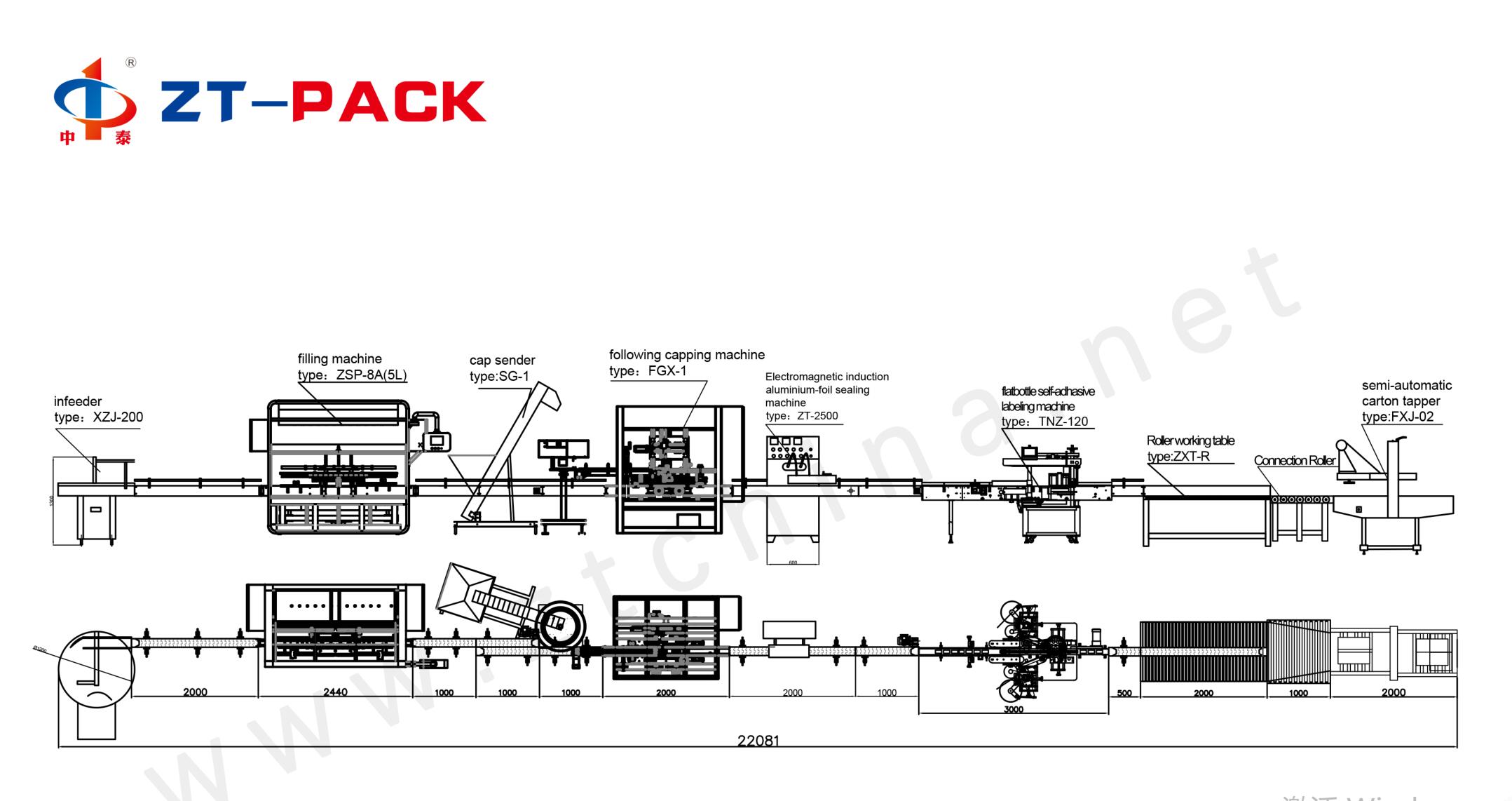

Layout Drawing :

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

Machine Name :

100ml -1000ml Full Automatic Edible Oil Filling Machine Packing Line

Ideal For Oil Filling Packing :

5: Filling Range : 50ml -1000ml

6: Bottle Shape : Round & Flat

7: Bottle Material : Plastic & Glass & Metal

Suitable for fill : Edible Oil / Cooking OIl / Sunflower Oil / Oil kinds Products

Filling Range : 50ml -1000ml

Speed can be choosen : from 1000BPH-6000BPH (basic on 1L )

Product description:

This Production Packing Line Suitable for Oils Filling , capping , labeling , date printer , carton packing machine , palletilizer

with high accuracy and suitable for different sizes and shapes of bottles without change parts

Automatically complete bottle unscramble, filling, capping, sealing, labeling, QR code, unpacking, packing, sealing, and palletizing, equipped with an integrated environmental protection cover. It conforms to the standards of safety, environmental protection and intelligent three-levelization, and the production process is automatically coordinated, which is stable and efficient.

In the fields of edible oil, food, etc., the filling production line adapts to different materials, bottle types, output, scenarios, etc. Design the corresponding filling production line. ZT-PACK starts from the needs of customers and provides fully automatic filling production lines. Automatic filling uses piston cylinder, servo motor, magnetic pump, rotor pump, weighing sensor, etc. as the material transmission system.

Suitable for Packing :

As shown in the pictures new cylinder liner in the piston bottom will be much more fexible than the unable disassembled and washed traditional cylinder, you can see touch screen and separate piston and cylinder liner, in order to easier cleaning for residual materials, easy choose different mode for different material or color.

1.widely used in filling machinery,especially suitable for filling viscous material.

2.Fast filling speed, prevision and stability

3.Delicate and small,esay for arrangement of pipe arrangement

4.special seal design at the bottom of the filling nozzle, filling without dripping

5.chamfering structure on the bottom of filling head, with orientation effect and submersible filling

Capacity Speed Choose :

Key Features :

Heavy-duty stainless steel constructed

Stainless steel Reservoir

Automatic Bottling Index kit with bottle counter

Pneumatic indexing gates (count in, count out)

Automatic product level sensing float system

Easily adjustable nozzle height settings accommodate vials to gallons

User friendly PLC controls with touch screen HMI

No bottle/No fill sensor

Bottle backup sensor (downstream) delays operation until jam is cleared

Able to output multiple doses per container for large containers

Easy clean stainless steel quick connect fittings

Drip Tray

Diving heads nozzles for bottom up filling to reduce foam

Neck grabbers for containers with small opening

Specifications are subject to change without notice, All rights are reserved.

Layout Drawing :

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com