| Availability: | |

|---|---|

| Quantity: | |

ZSP-A

ZT-PACK

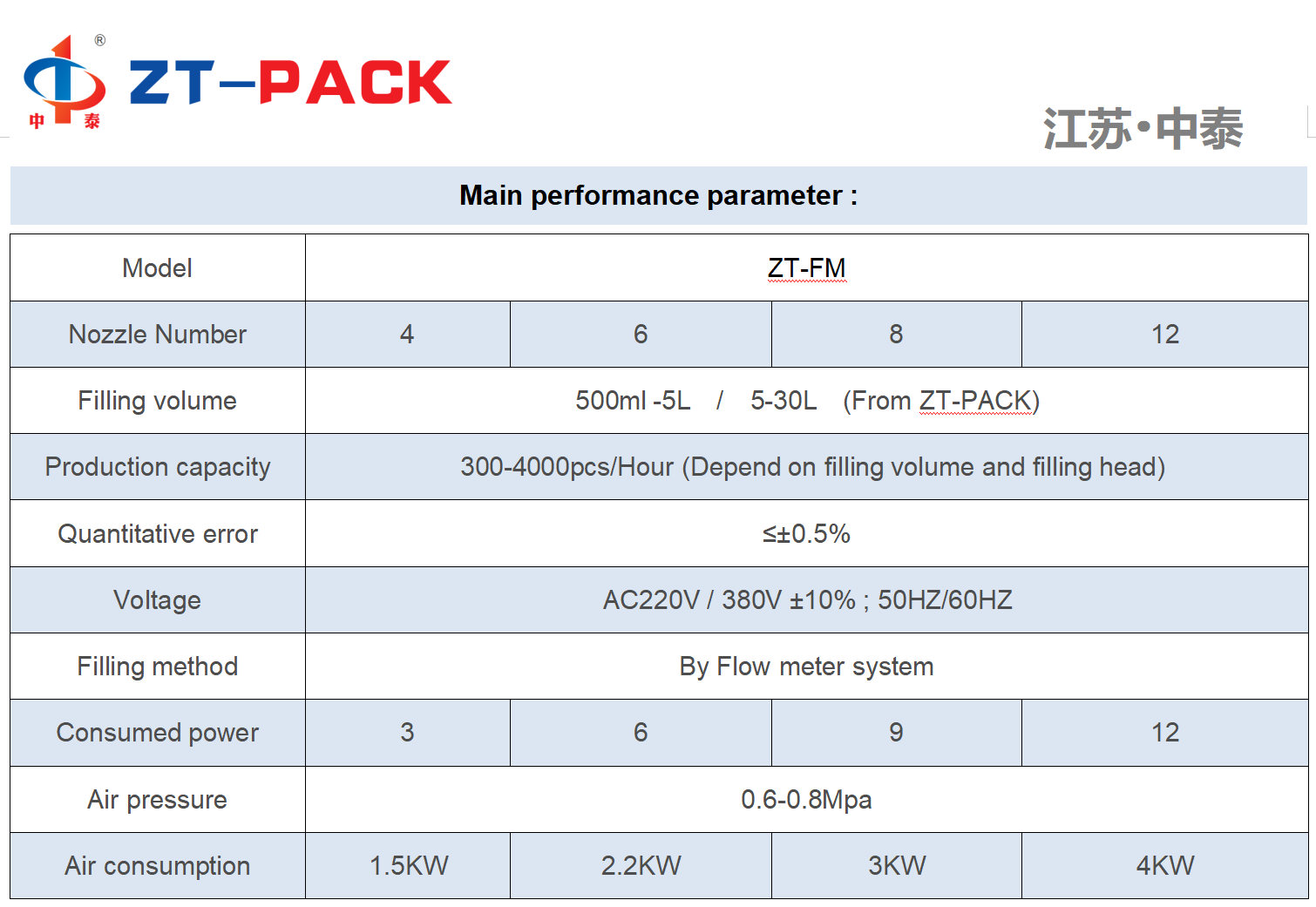

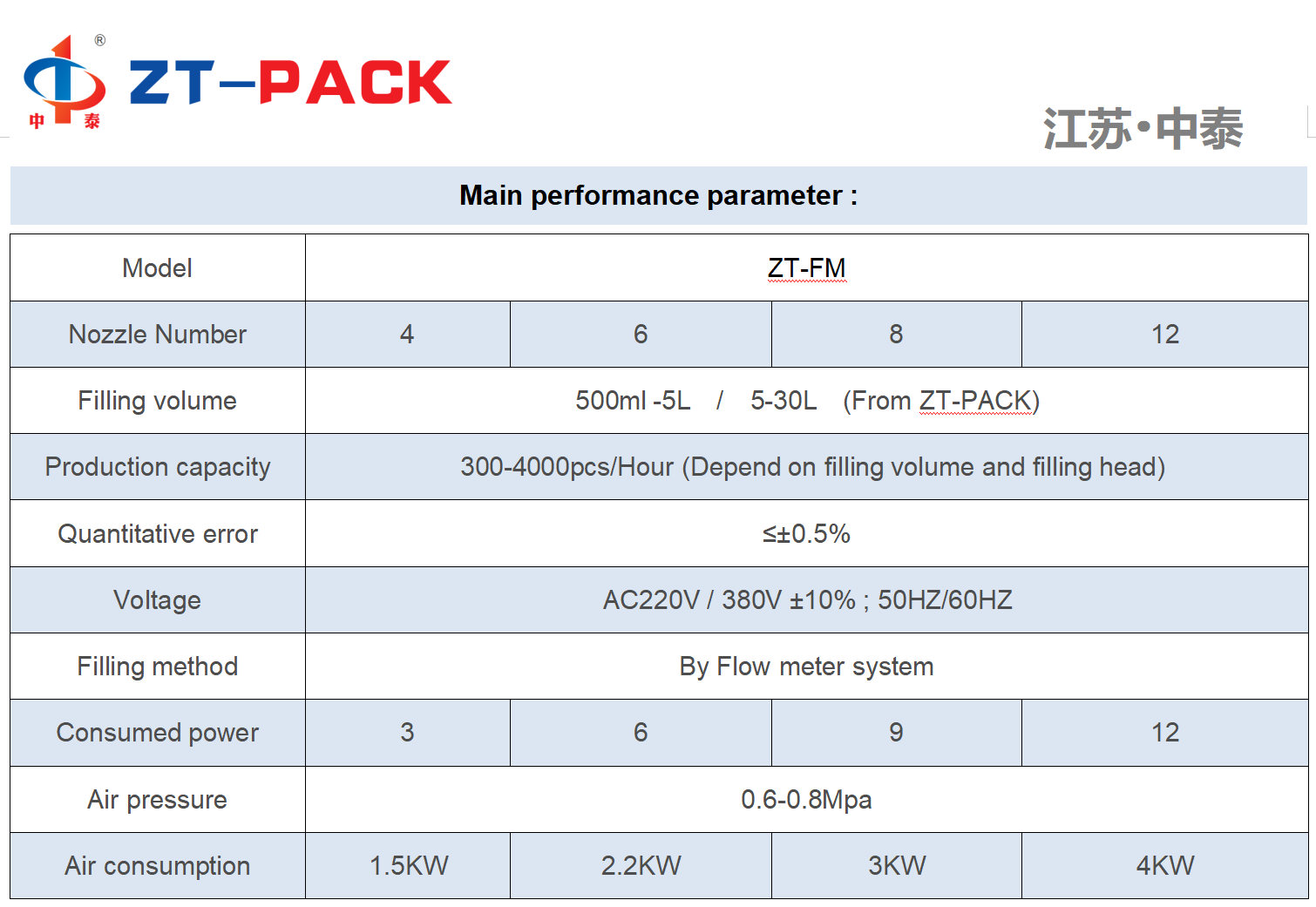

Machine Name : 0.5L-7L Flow Meter Type Full Automatic Edible Oil Filling Machine

Type: ZSP-A

Suitable For Filling: Edible Oil / Cookie Oil / Sunflower Oil / Olive Oil / Peanut Oil / Rapeseed Oil /Soybean Oil ...Etc kinds Products

Filling Range : 0.5L-7L

Filling System : Flow Meter

Accuracy : 0.5%

Product description:

This machine is a piston Type filling machine with high filling accuracy.

It applies to 0.5-5L liquid for filling.

Filling system can be choose: Flow meter

Widely use for edible oil packing industries

It is produced with the GMP standards, safety, environmental hygienism, beautiful and adapt to different kinds of work place.

This filling machine combined with a bottle unscrambler, a capping machine, a labeling machine and other machines can automatically complete bottle unscramble, filling, capping, sealing, labeling, QR code, unpacking, packing, sealing, and palletizing, equipped with an integrated environmental protection cover. It conforms to the standards of safety, environmental protection and intelligent three-levelization, and the production process is automatically coordinated, which is stable and efficient.

Suitable for Fill :

Details for Filling Machine :

As shown in the pictures new cylinder liner in the piston bottom will be much more fexible than the unable disassembled and washed traditional cylinder, you can see touch screen and separate piston and cylinder liner, in order to easier cleaning for residual materials, easy choose different mode for different material or color.

1.widely used in filling machinery,especially suitable for filling viscous material.

2.Fast filling speed, prevision and stability

3.Delicate and small,esay for arrangement of pipe arrangement

4.special seal design at the bottom of the filling nozzle, filling without dripping

5.chamfering structure on the bottom of filling head, with orientation effect and submersible filling

Key Features :

Machines Frame Parts Made by high quality 304 Stainless steel, it is durable.

316 stainless steel product contact parts as standard

Dosing system is driven by servo motor, it assure high filling accuracy.

Liquid receive tray is available in case any dripping from filling nozzle.

Air blow off filling nozzle is available for sticky product to avoid tail stringing on nozzle

CIP Product hopper

No bottle no fill.

Linear structure which is flexible for varies bottle size.

Controlled by PLC and operation through touch screen.

No tooling needed to change over different size bottles.

Quick-install connecting parts , it is easy to disassemble and clear machine.

As the name suggests, Automatic Edible Oil Filling Line is a setup of multiple machinery arranged in line and synchronization with one other so as to perform the ultimate function of edible oil filling. We are suppliers and exporters for the complete Edible Oil Filling Machines.

Our range of Automatic Edible Oil Filling Machines comprises of Continuous Liquid Filling Machine as well as Servo Controlled Liquid Filling Machine.

with Piston system / flow meter system / net weight load cell system all suitable for oils packing

These machines are fabricated by our team of qualified engineers and technicians with the use of finest technology and components to bring out a superlative quality.

Standard Details for our Edible Oil Filling Line

Versatile: The machinery is very versatile to fill different capacity range from 500 ml to 10000 ml. It has minimum adjustment requirement. (by flow meter )

Drip Free: The oil filling Machine is ‘drip free’ with well designed nozzles ensuring repeat recycling of sequences. Diving nozzle arrangement with drip tray is provided.

Accuracy: Repeat accuracy of filling is +/-0.25% of the filled volume.

Safety Device: “No bottles no fill” sensor will ensure that filling does not take place when bottles are not in alignment with the nozzle.

Electronic Controls: The oil filling machine will be equipped with PLC for controls of function of the machines.

Standard Accessories: The oil filling machine will be equipped with a separate pump set as well as motorized slat chain conveyor made in SS.

Change Over: Minimum change over time is required while changing from one pack size to other pack size.

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

Machine Name : 0.5L-7L Flow Meter Type Full Automatic Edible Oil Filling Machine

Type: ZSP-A

Suitable For Filling: Edible Oil / Cookie Oil / Sunflower Oil / Olive Oil / Peanut Oil / Rapeseed Oil /Soybean Oil ...Etc kinds Products

Filling Range : 0.5L-7L

Filling System : Flow Meter

Accuracy : 0.5%

Product description:

This machine is a piston Type filling machine with high filling accuracy.

It applies to 0.5-5L liquid for filling.

Filling system can be choose: Flow meter

Widely use for edible oil packing industries

It is produced with the GMP standards, safety, environmental hygienism, beautiful and adapt to different kinds of work place.

This filling machine combined with a bottle unscrambler, a capping machine, a labeling machine and other machines can automatically complete bottle unscramble, filling, capping, sealing, labeling, QR code, unpacking, packing, sealing, and palletizing, equipped with an integrated environmental protection cover. It conforms to the standards of safety, environmental protection and intelligent three-levelization, and the production process is automatically coordinated, which is stable and efficient.

Suitable for Fill :

Details for Filling Machine :

As shown in the pictures new cylinder liner in the piston bottom will be much more fexible than the unable disassembled and washed traditional cylinder, you can see touch screen and separate piston and cylinder liner, in order to easier cleaning for residual materials, easy choose different mode for different material or color.

1.widely used in filling machinery,especially suitable for filling viscous material.

2.Fast filling speed, prevision and stability

3.Delicate and small,esay for arrangement of pipe arrangement

4.special seal design at the bottom of the filling nozzle, filling without dripping

5.chamfering structure on the bottom of filling head, with orientation effect and submersible filling

Key Features :

Machines Frame Parts Made by high quality 304 Stainless steel, it is durable.

316 stainless steel product contact parts as standard

Dosing system is driven by servo motor, it assure high filling accuracy.

Liquid receive tray is available in case any dripping from filling nozzle.

Air blow off filling nozzle is available for sticky product to avoid tail stringing on nozzle

CIP Product hopper

No bottle no fill.

Linear structure which is flexible for varies bottle size.

Controlled by PLC and operation through touch screen.

No tooling needed to change over different size bottles.

Quick-install connecting parts , it is easy to disassemble and clear machine.

As the name suggests, Automatic Edible Oil Filling Line is a setup of multiple machinery arranged in line and synchronization with one other so as to perform the ultimate function of edible oil filling. We are suppliers and exporters for the complete Edible Oil Filling Machines.

Our range of Automatic Edible Oil Filling Machines comprises of Continuous Liquid Filling Machine as well as Servo Controlled Liquid Filling Machine.

with Piston system / flow meter system / net weight load cell system all suitable for oils packing

These machines are fabricated by our team of qualified engineers and technicians with the use of finest technology and components to bring out a superlative quality.

Standard Details for our Edible Oil Filling Line

Versatile: The machinery is very versatile to fill different capacity range from 500 ml to 10000 ml. It has minimum adjustment requirement. (by flow meter )

Drip Free: The oil filling Machine is ‘drip free’ with well designed nozzles ensuring repeat recycling of sequences. Diving nozzle arrangement with drip tray is provided.

Accuracy: Repeat accuracy of filling is +/-0.25% of the filled volume.

Safety Device: “No bottles no fill” sensor will ensure that filling does not take place when bottles are not in alignment with the nozzle.

Electronic Controls: The oil filling machine will be equipped with PLC for controls of function of the machines.

Standard Accessories: The oil filling machine will be equipped with a separate pump set as well as motorized slat chain conveyor made in SS.

Change Over: Minimum change over time is required while changing from one pack size to other pack size.

How to choose automatic piston filling machine is big challenge for customers, If your are unsure how to choose a piston filling machine,Please let me know

What product to fill

What output capacity to achieve

What material and shape of containers

What size of containers to fill

Our professional team will help you to choose

So please contact us for specific advice on the best solution for you now.

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com