| Availability: | |

|---|---|

| Quantity: | |

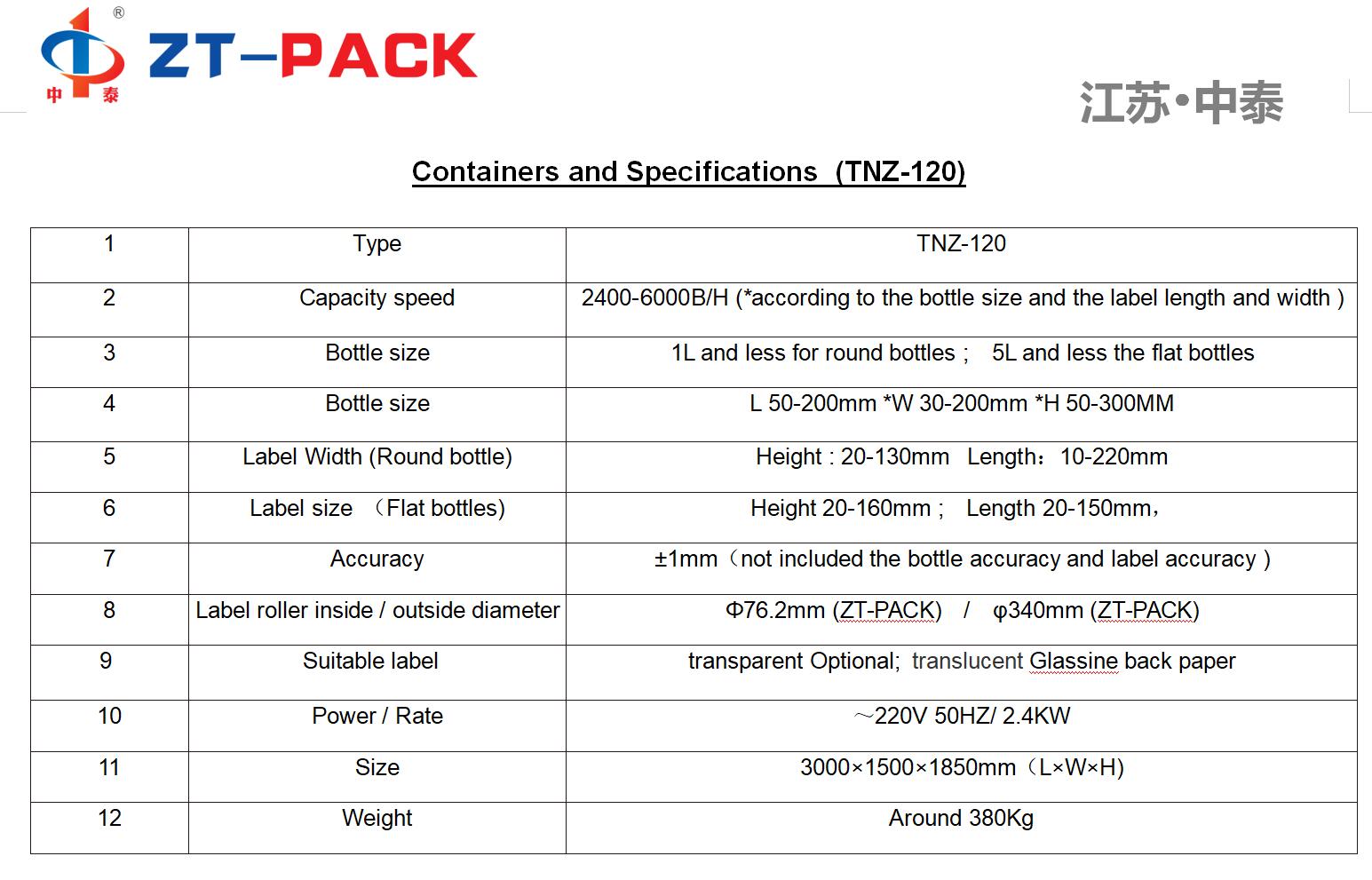

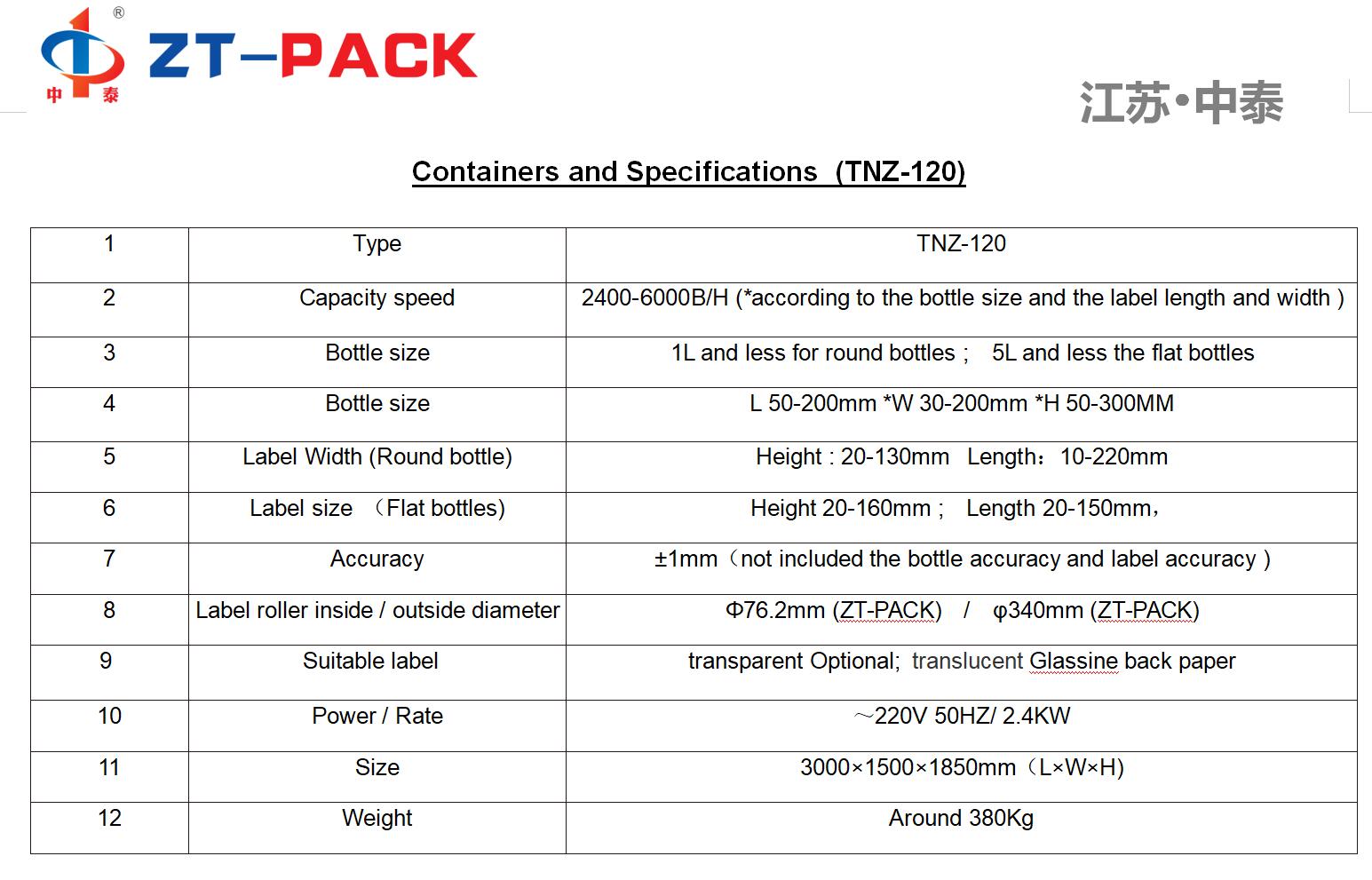

TNZ-120

ZT-PACK

Machine Name : Two Sides Front And Back Self-adhesive Labeling Machine

Type : TNZ-120

Machine Description :

Automatic double side front and back self adhesive labelling machine for bottles is design to handle a wide range of self-adhesive labelling applications with speed and accuracy in either single, twin or tri-labelling head configuration can apply front, back, partial wrap or full wrap labels as well as tamper evident or promotional top labels.

Two label dispensers operates independently for one side labeling or operate simultaneously for two side labeling which allows different size of label application on either side, An optional wrap station is offered for partial wrap or full wrap labels as well as tamper evident or promotional top labels.

Front and Back sticker labeler machine is equipped with a chain aligner system for product orientation, ensuring correct positioning of the containers before the label is applied.

The container position is adjusted by the spring mounted motorized chains before it moves under the head gripper where it is released.

The head gripper is mounted on a vertical stainless steel spindle system for easy adjustment when needed. Additional features includes stainless steel construction and anodize components, world famous electronic components, servo motor drive, powered assist web take up, PLC control and user friendly HMI.

It is suitable for the surface labeling of the square, flat and round bottles, widely used for medicine, household chemicals, foodstuff, cultural supplies and so on.

1. Automatically label 1 or 2 side, or wrapping around on round bottle(optional).

2. Adopting PLC control unit

3. Use easy operation large touch screen

4. Adopt label sensor & object sensor

5. Can be equipped with coding machine or printing machine, print clearly. (optional )

6. High labeling speed and high precision

Hot stamp printing coder with base (prints characters directly onto the label)

Clear Label Sensors (capable of detecting transparent labels)

Wraparound station

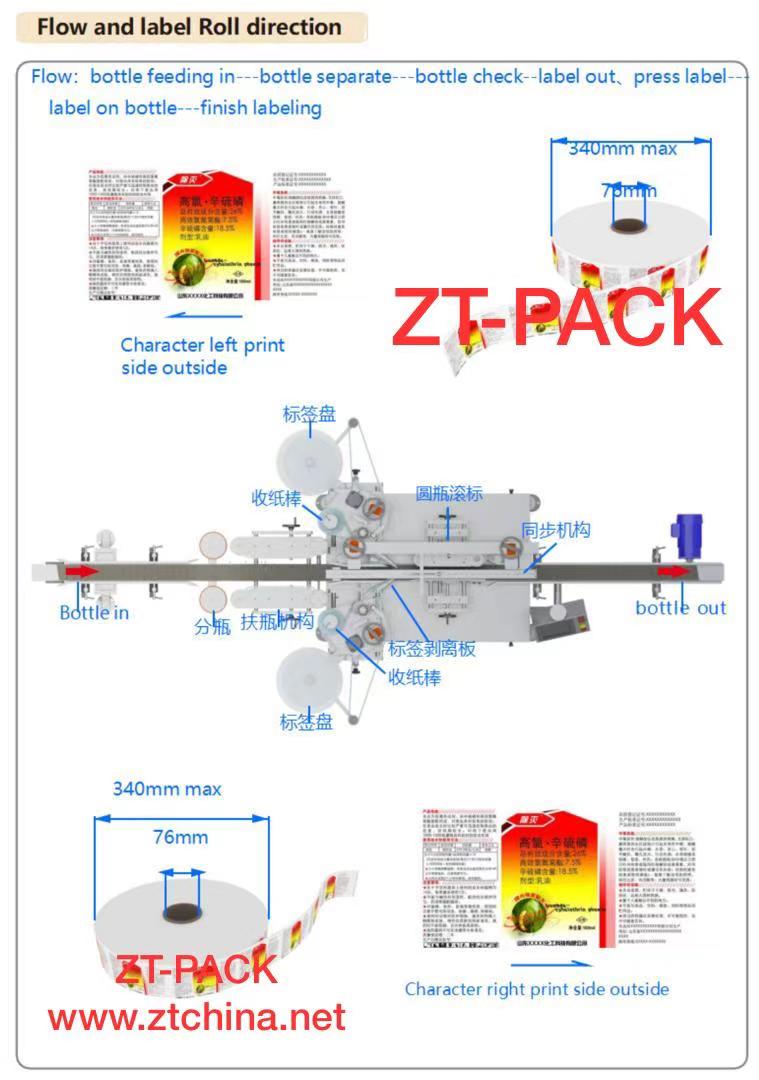

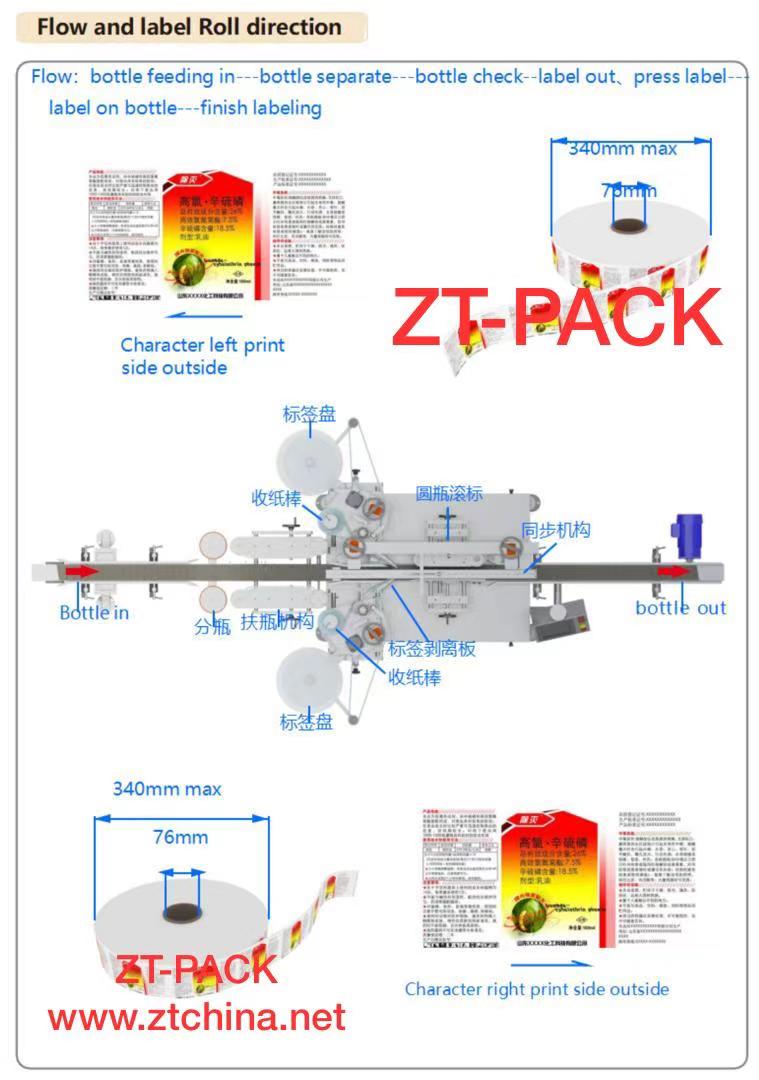

Workflow Description :

Bottle in→ check → labeling→stroke label → finished products

When bottle in labeling machine , firstly cheaking position.The bottle correction before enter the pressure is mechanism,Pressure is mechanism of action is to make the bottle can stable, no any dithering to walk ahead。stick mark position, through the sensor detection signal start out standard action, starting labeling .When labeled bottle forward to stroke, stroke label will on both sides of the label on the bottle to stick, then complete the labeling process.

Details Pictures :

Heavy-duty stainless steel constructed anodized aluminium components

Electronic components are world famous brand

Capable of labeling flat,oval,square and round containers

Variable speed bottle infeed seperator wheel

PLC control and user friendly HMI

Servo motor drive delivers accurate and high-speed repeatable labeling

Top stabilizing/conveyor belt is provided to hold the bottle for proper labeling.

Automatic synchronized label head and conveyor belt

Power assisted web take up

Low or missing label detection with automatic stop system to prevent mislabeling

Non-contact photo eye sensors

Label counter

Machine Name : Two Sides Front And Back Self-adhesive Labeling Machine

Type : TNZ-120

Machine Description :

Automatic double side front and back self adhesive labelling machine for bottles is design to handle a wide range of self-adhesive labelling applications with speed and accuracy in either single, twin or tri-labelling head configuration can apply front, back, partial wrap or full wrap labels as well as tamper evident or promotional top labels.

Two label dispensers operates independently for one side labeling or operate simultaneously for two side labeling which allows different size of label application on either side, An optional wrap station is offered for partial wrap or full wrap labels as well as tamper evident or promotional top labels.

Front and Back sticker labeler machine is equipped with a chain aligner system for product orientation, ensuring correct positioning of the containers before the label is applied.

The container position is adjusted by the spring mounted motorized chains before it moves under the head gripper where it is released.

The head gripper is mounted on a vertical stainless steel spindle system for easy adjustment when needed. Additional features includes stainless steel construction and anodize components, world famous electronic components, servo motor drive, powered assist web take up, PLC control and user friendly HMI.

It is suitable for the surface labeling of the square, flat and round bottles, widely used for medicine, household chemicals, foodstuff, cultural supplies and so on.

1. Automatically label 1 or 2 side, or wrapping around on round bottle(optional).

2. Adopting PLC control unit

3. Use easy operation large touch screen

4. Adopt label sensor & object sensor

5. Can be equipped with coding machine or printing machine, print clearly. (optional )

6. High labeling speed and high precision

Hot stamp printing coder with base (prints characters directly onto the label)

Clear Label Sensors (capable of detecting transparent labels)

Wraparound station

Workflow Description :

Bottle in→ check → labeling→stroke label → finished products

When bottle in labeling machine , firstly cheaking position.The bottle correction before enter the pressure is mechanism,Pressure is mechanism of action is to make the bottle can stable, no any dithering to walk ahead。stick mark position, through the sensor detection signal start out standard action, starting labeling .When labeled bottle forward to stroke, stroke label will on both sides of the label on the bottle to stick, then complete the labeling process.

Details Pictures :

Heavy-duty stainless steel constructed anodized aluminium components

Electronic components are world famous brand

Capable of labeling flat,oval,square and round containers

Variable speed bottle infeed seperator wheel

PLC control and user friendly HMI

Servo motor drive delivers accurate and high-speed repeatable labeling

Top stabilizing/conveyor belt is provided to hold the bottle for proper labeling.

Automatic synchronized label head and conveyor belt

Power assisted web take up

Low or missing label detection with automatic stop system to prevent mislabeling

Non-contact photo eye sensors

Label counter

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com