Views: 0 Author: Site Editor Publish Time: 2022-08-17 Origin: Site

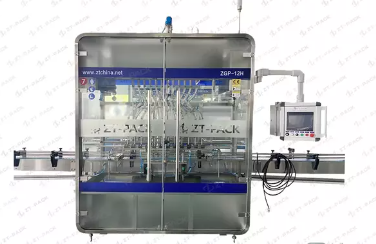

The pesticide filling machine is a new variety of filling machine with simple structure and high accuracy.So currently let me introduce you one thing concerning it!

Here is that the content:

l Brief description of functions

l Main performance and characteristics

l Workflow of pesticide filling machine

l Scope of application

(1) Needle filling head:

It is appropriate for filling small-caliber bottles and hose packaging merchandise. Part of the needle diameter and length will be custom-built in keeping withthe precise size of the container.

(2) Rotary/ball valve control system:

Suitable for materials with totally different viscosities and particles, and can solve numerous pressure problems caused by high-level and aggressive feeding.

(3) Hopper:

It is suggested that the merchandise with high consistency ought to be filled to attain better filling effect.

(1) New horizontal style, lightweight and convenient, automatic pumping, for thick paste will be fed by hopper.The material cylinder and also the tee joint are connected by handcuffs, without any special tools,therefore it is terribly convenient to load, unload and clean.

(2) KL Granule Slurry Filling Machine is a product of our company, which is reformed and innovatively designed on the basis of advanced filling machine technology. Its structure is simple, its accuracy is high, and its operation is easier.

(3) This machine is a semi-automatic piston filling machine, which can fill granular slurry fluid materials.

(4) The machine has reasonable design, small size, vertical structure, saving space and convenient operation.

(5) Pneumatic components from FESTO in Germany and AirTac in Taiwan Province are used in pneumatic parts.

(6) The contact parts are all made of 316L stainless steel, which meets GMP requirements.

(7) The filling valve is controlled by pneumatic valve, so the filling accuracy is higher.

(8) The filling quantity and filling speed can be adjusted at will.

(9) The filling head adopts anti-drawing and lifting filling device.

Boxes filled with empty bottles are stacked on pallets, which are transported to the pallet unloader by conveyor belt, and the pallets are unloaded one by one. Boxes are transported to the unloader by conveyor belt, and empty bottles are taken out of the boxes. Empty boxes are transported to the box washer by conveyor belt, cleaned, and then transported to the box loader, so that bottles filled with drinks can be loaded into them. The empty bottles taken out of the box unloader are sent to the bottle washer for disinfection and cleaning by another conveyor belt. After inspection by the bottle tester, they meet the cleaning standards and then enter the filling machine and capping machine. The beverage is filled into a bottle by a filling machine. Bottles filled with beverages are sealed by capping machine and sent to labeling machine for labeling. After labeling, they are sent to packing machine for packing, then sent to pallet stacking machine for stacking on pallets and then sent to warehouse.

This filling machine is suitable for medicine, daily chemical, food, pesticide and special industries, and is an ideal filling machine for granular slurry viscosity fluid.

If you want to make better use of pesticide filling machine in more aspects, then ZT-pack must come and have a look. We have a very comprehensive range of filling machine, which can meet your needs anywhere.

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com