| Availability: | |

|---|---|

| Quantity: | |

FGX-1

ZT-PACK

Machine Name : Full Automatic Tracking Following Type Capping Machine

Type : FGX-1

Machine Description :

FXG-1 full-automatic following lid-pressing machine is made up of lid unscrambler and lid conveyer, grasp and lid-pressing system, movement module,conveying mechanism and control system. The whole structure is succinct and convenient to adjust. It is suitable for the automatic lid-pressing for 500ml -5L bottle. This is a most recently develop machine of our company. The lid-pressing will be finished during the process of products movement.Differs from the nomal machine which need to pause when lid-pressing so that the materials will not shake out from the mouth of the bottleand pollute the bottle’s body.

Major characteristics :

This is our newly developed tracking type capping machine, integrates bottle inlet, cap sort, cap feed, capping, bottle outlet together, bottle inlet by belt clamping and cap screwing by tracking capping head, during capping, the bottle will not stop, bottle moving and capping action at the same time, can avoid liquid spill, adopts servo control torque capping, harmless to bottle and cap, fast speed, safe and stable, high capping rate. Whole machine using PLC and touch screen automation control, widely applicability and convenient adjustment.

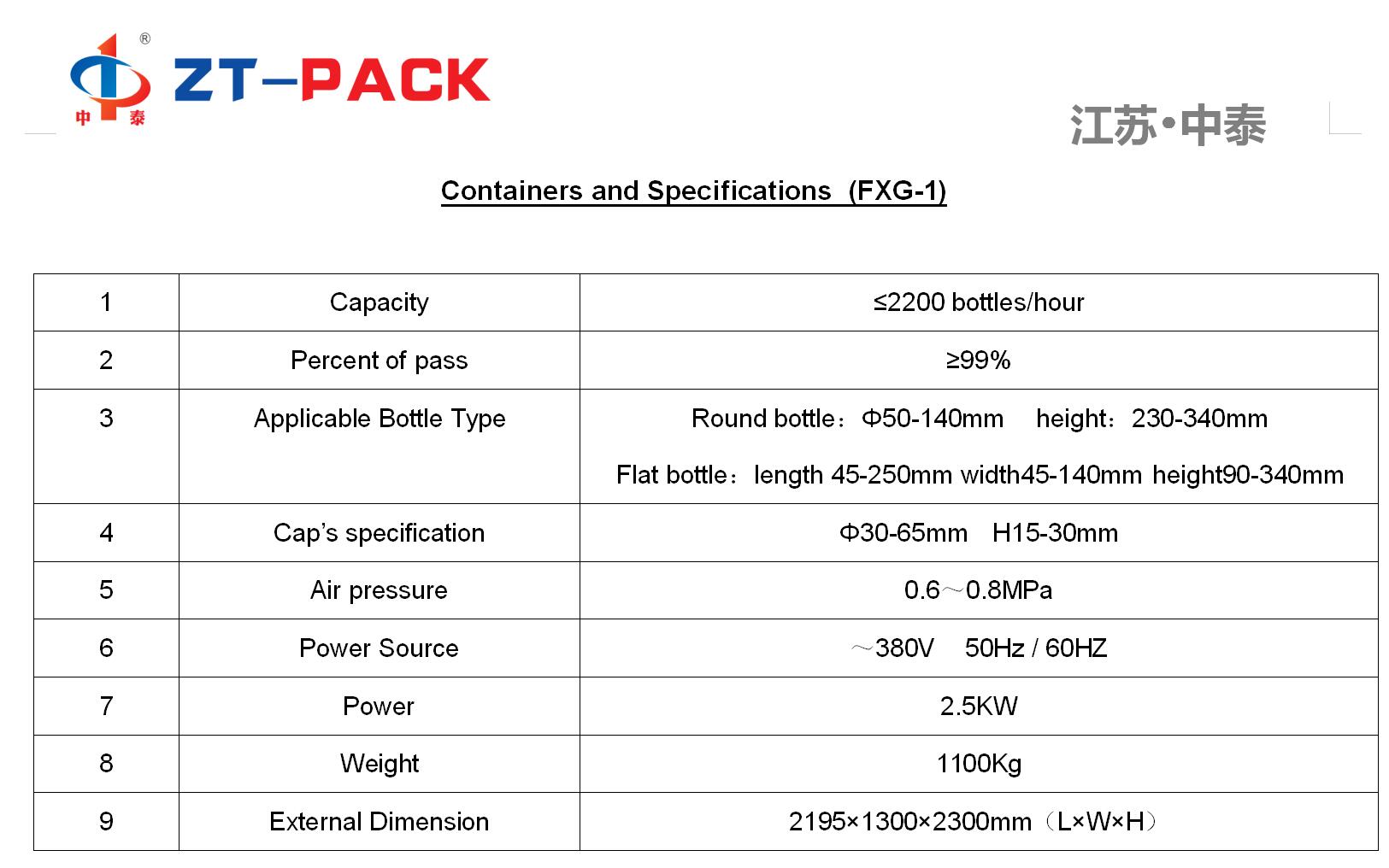

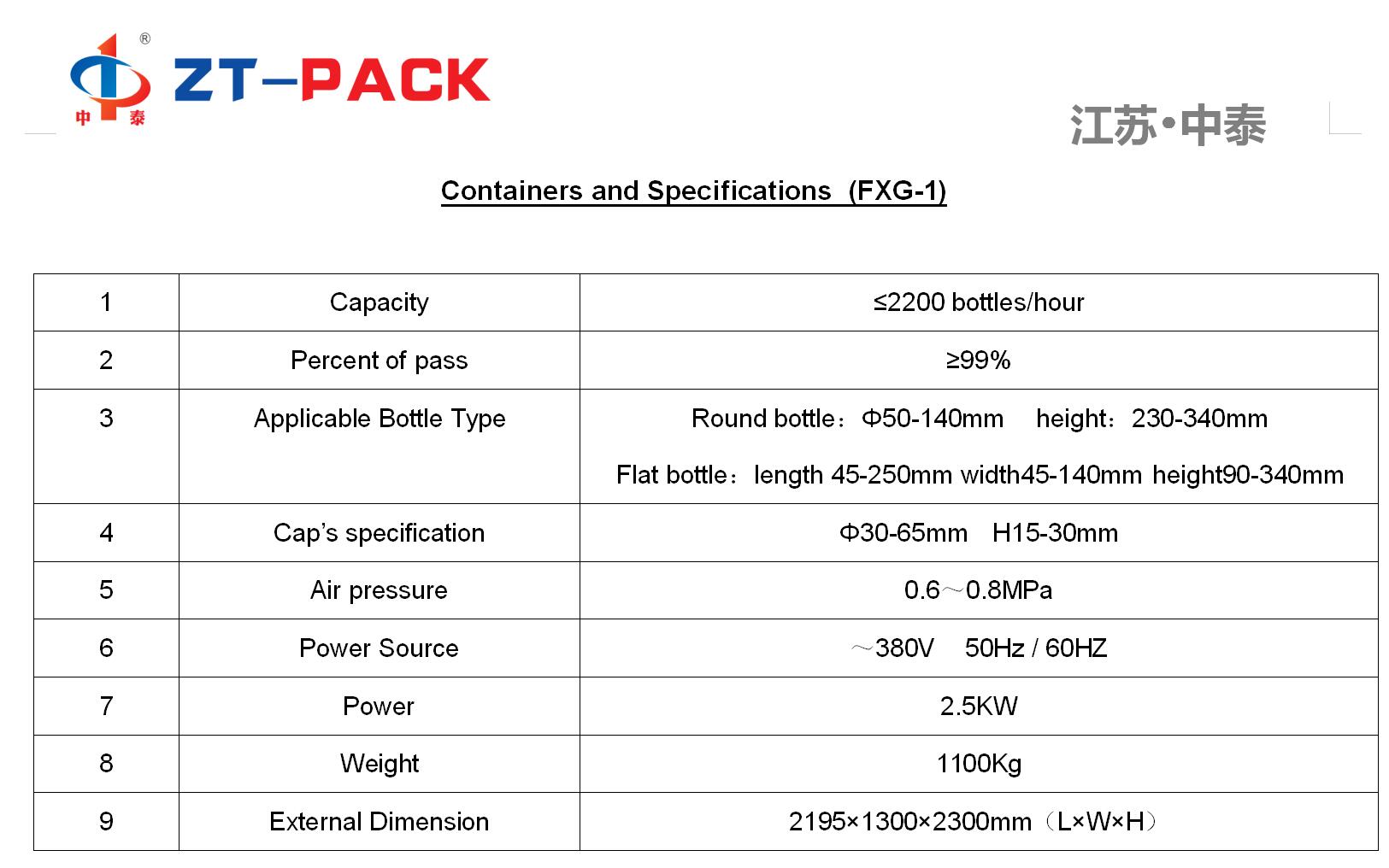

Main Technical Parameter:

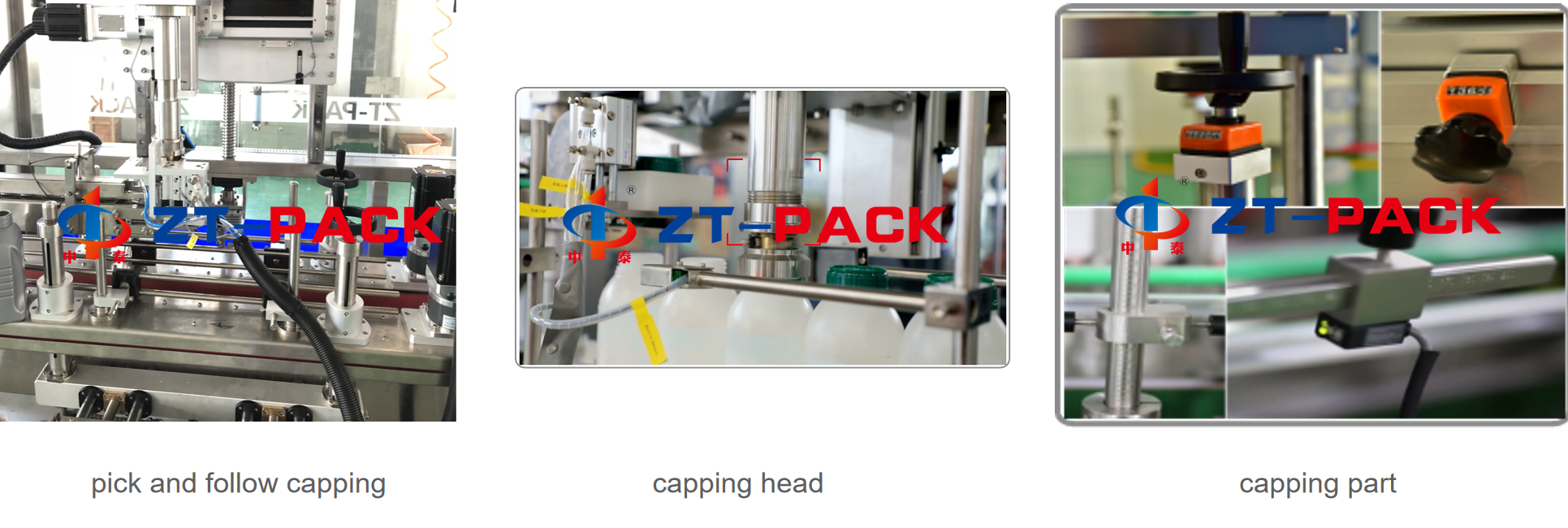

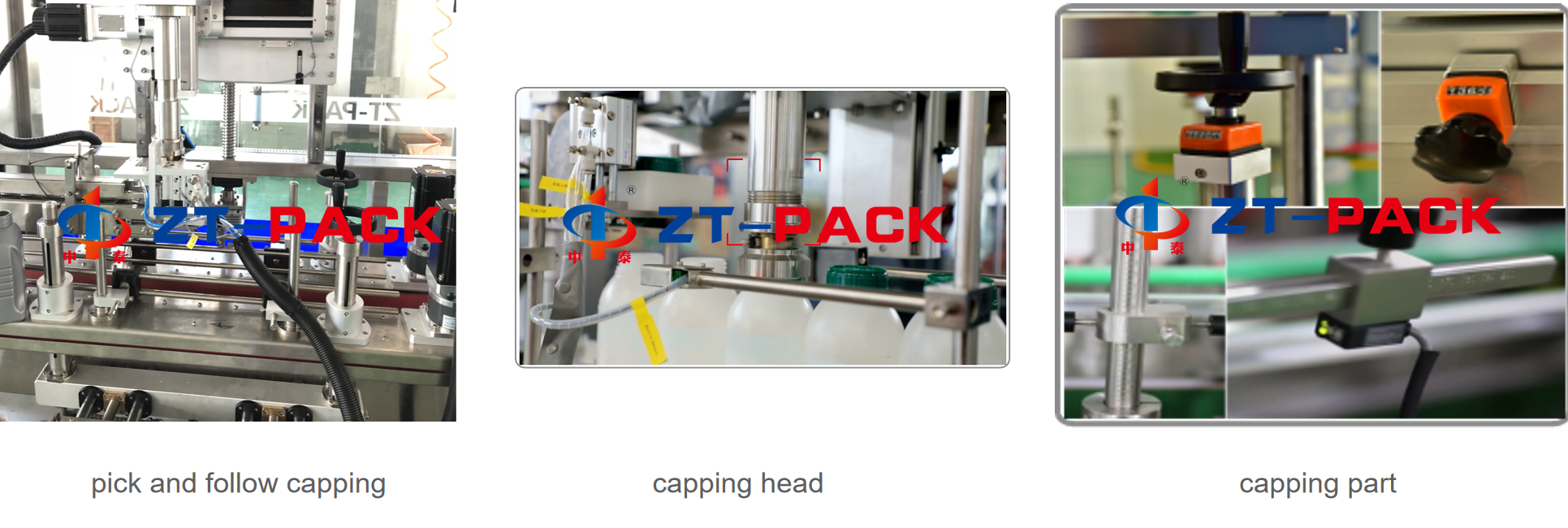

Details Pictures :

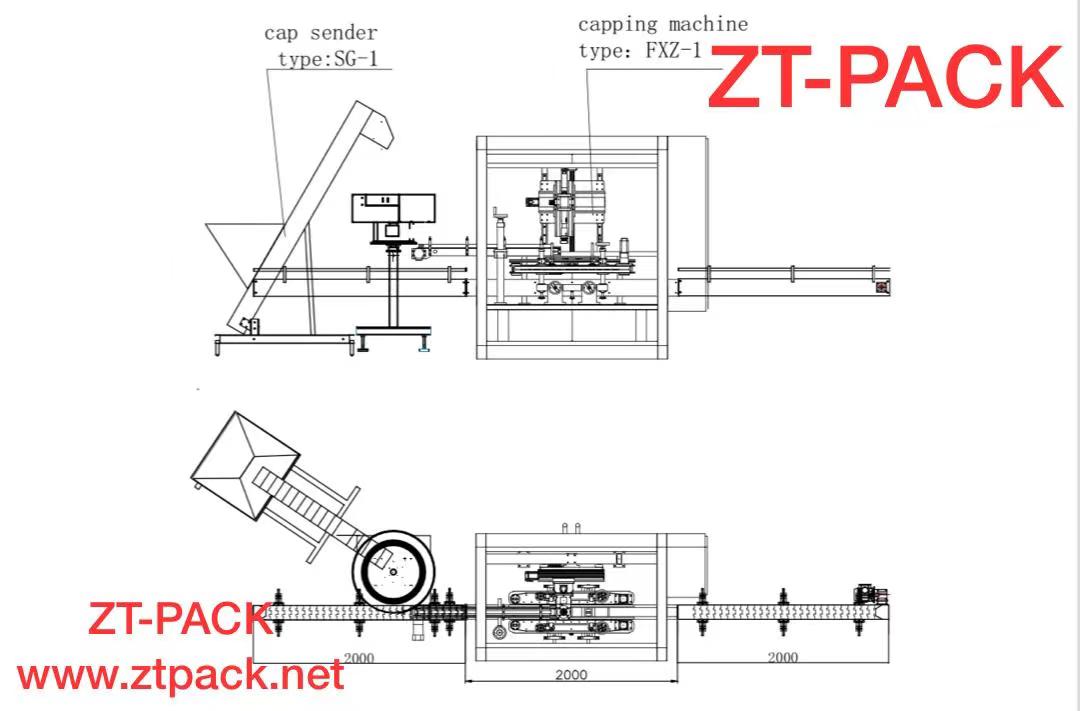

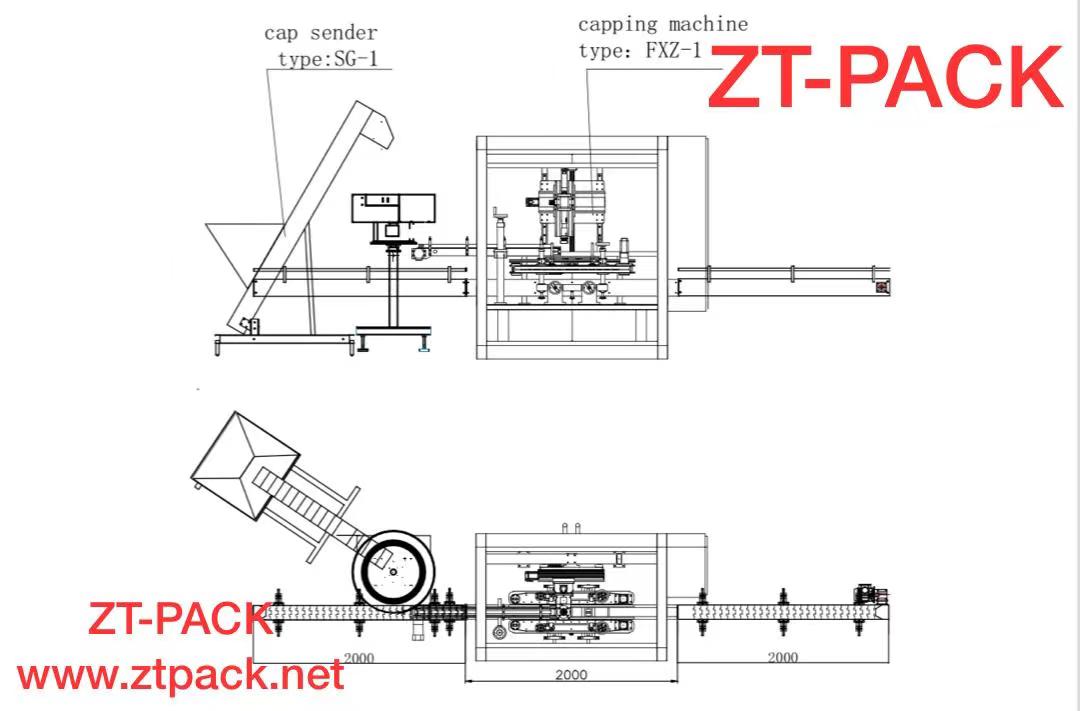

Layout Drawing :

Key Features :

Non-stop working mode – capping during constant flow of packages.

Capping with back-turn which increases production capacity and eliminates rejected packages.

Equipped with a closure correctness verification system.

Capping torque is set in the control panel.

Fast and easy capping head changeover into another cap type.

Machine Name : Full Automatic Tracking Following Type Capping Machine

Type : FGX-1

Machine Description :

FXG-1 full-automatic following lid-pressing machine is made up of lid unscrambler and lid conveyer, grasp and lid-pressing system, movement module,conveying mechanism and control system. The whole structure is succinct and convenient to adjust. It is suitable for the automatic lid-pressing for 500ml -5L bottle. This is a most recently develop machine of our company. The lid-pressing will be finished during the process of products movement.Differs from the nomal machine which need to pause when lid-pressing so that the materials will not shake out from the mouth of the bottleand pollute the bottle’s body.

Major characteristics :

This is our newly developed tracking type capping machine, integrates bottle inlet, cap sort, cap feed, capping, bottle outlet together, bottle inlet by belt clamping and cap screwing by tracking capping head, during capping, the bottle will not stop, bottle moving and capping action at the same time, can avoid liquid spill, adopts servo control torque capping, harmless to bottle and cap, fast speed, safe and stable, high capping rate. Whole machine using PLC and touch screen automation control, widely applicability and convenient adjustment.

Main Technical Parameter:

Details Pictures :

Layout Drawing :

Key Features :

Non-stop working mode – capping during constant flow of packages.

Capping with back-turn which increases production capacity and eliminates rejected packages.

Equipped with a closure correctness verification system.

Capping torque is set in the control panel.

Fast and easy capping head changeover into another cap type.

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com