| Availability: | |

|---|---|

| Quantity: | |

ZT-PACK

Collaborative Robot Palletizer

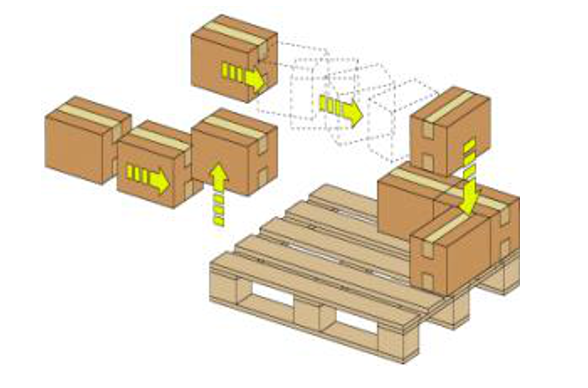

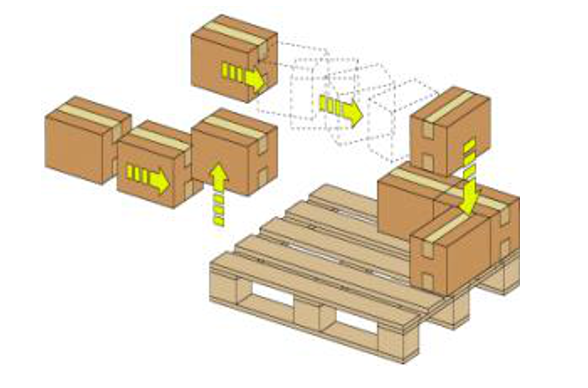

This machine is suitable for oil, beverage, food, beer, plastic, air-conditioning and other production companies. It palletized of finished cartons, bags, cans, boxes, bottles and boxes. A very simple structure, easy maintenance and repair; few main constituent parts, small parts, so maintenance costs low; robotic palletizer can be installed in a narrow space, you can effectively use; Full Control can operate on that screen, the operation is very simple. All-weather operations, the machine can replace of labor working. So it can save hundreds of thousands of human resources costs, reaching shedding workers! Scope: corrugated boxes, plastic boxes, barrel packaging, pouch-like packaging.

Collaborative Robot

1: no need fencing , when hit by anything , machine stop itself

2: compare with industry robot , this no need maintenance ,industry robot need every year

3; speed 8-10 carton boxes / min ( speed influenced by carton boxes weight )

4: easy to add / modify data

Major characteristics:

The robot palletizer can be used in many production line, providing intelligent, mechanization for production site. It is a palletising logistic system which can be used in the industries of beer, water, soft drink, milk, beverage and foodstuff etc. It is widely used for carton, plastic crate, bottle, bag, barrel, shrink wrapped product and can etc.

Main Features:

A. Ttouch-screen operation achieves man-machine communication, displaying the production speed, failure reason and position.

B. The product palletizing patterns, pallet supply and discharging can all be programmed by PLC.

C. Palletizing pattern is easy to adjust on the touchscreen.

D. Carton supply system adopts brake motor control to ensure carton conveying according to pre-set position.

E. Pallet magazine has a high capacity of 12-15 empty pallet ensuring automatically pallet supply.

F. Different palletizing patterns can be finished without replacing the palletizing components.

Advantages:

Safety and stability

(1) Ability to work directly with humans without the need for safety fences for isolation, with high reliability and safety;

(2) Supports 10-level collision detection and sensor safety detection;

(3) Provides 16 safety I/O interfaces, and will not lose safety functions in the event of a single failure;

(4) The terminal will not fall when power is off, and the product is safe and stable;

Flexible deployment

(1) Integrated design, light and flexible, small footprint;

(2) New task settings for workstation deployment are simple and fast, with high efficiency;

Simple programming

(1) You can master the programming method in half an hour and complete simple programming in one hour;

(2) Visual programming is simple and efficient, and you can easily operate the robot without being proficient in programming languages;

Flexible production

Quick switching of multiple functional scenarios, flexible production can be achieved through human-machine collaboration, dual-machine collaboration, multi-machine collaboration, etc.;

Wide application

Widely used in food, medicine, 3C, daily chemicals, e-commerce and other industries.

Parameters | |

Driver | WARSONCO |

Servo motor | WARSONCO |

Controller | KEBA |

Reducer | LAIFUAL |

Switching power supply | MEAN WELL |

Air source | 0.5-0.8Mpa (vacuum generator) |

Air consumption | 350-450nl/min |

Power supply | 220VAC 50Hz ± 10% |

Maximum power consumption | 5KW |

Total weight | ≈350kg |

Carton size | According to user requirements |

Stacking method | According to user requirements |

Collaborative Robot Palletizer

This machine is suitable for oil, beverage, food, beer, plastic, air-conditioning and other production companies. It palletized of finished cartons, bags, cans, boxes, bottles and boxes. A very simple structure, easy maintenance and repair; few main constituent parts, small parts, so maintenance costs low; robotic palletizer can be installed in a narrow space, you can effectively use; Full Control can operate on that screen, the operation is very simple. All-weather operations, the machine can replace of labor working. So it can save hundreds of thousands of human resources costs, reaching shedding workers! Scope: corrugated boxes, plastic boxes, barrel packaging, pouch-like packaging.

Collaborative Robot

1: no need fencing , when hit by anything , machine stop itself

2: compare with industry robot , this no need maintenance ,industry robot need every year

3; speed 8-10 carton boxes / min ( speed influenced by carton boxes weight )

4: easy to add / modify data

Major characteristics:

The robot palletizer can be used in many production line, providing intelligent, mechanization for production site. It is a palletising logistic system which can be used in the industries of beer, water, soft drink, milk, beverage and foodstuff etc. It is widely used for carton, plastic crate, bottle, bag, barrel, shrink wrapped product and can etc.

Main Features:

A. Ttouch-screen operation achieves man-machine communication, displaying the production speed, failure reason and position.

B. The product palletizing patterns, pallet supply and discharging can all be programmed by PLC.

C. Palletizing pattern is easy to adjust on the touchscreen.

D. Carton supply system adopts brake motor control to ensure carton conveying according to pre-set position.

E. Pallet magazine has a high capacity of 12-15 empty pallet ensuring automatically pallet supply.

F. Different palletizing patterns can be finished without replacing the palletizing components.

Advantages:

Safety and stability

(1) Ability to work directly with humans without the need for safety fences for isolation, with high reliability and safety;

(2) Supports 10-level collision detection and sensor safety detection;

(3) Provides 16 safety I/O interfaces, and will not lose safety functions in the event of a single failure;

(4) The terminal will not fall when power is off, and the product is safe and stable;

Flexible deployment

(1) Integrated design, light and flexible, small footprint;

(2) New task settings for workstation deployment are simple and fast, with high efficiency;

Simple programming

(1) You can master the programming method in half an hour and complete simple programming in one hour;

(2) Visual programming is simple and efficient, and you can easily operate the robot without being proficient in programming languages;

Flexible production

Quick switching of multiple functional scenarios, flexible production can be achieved through human-machine collaboration, dual-machine collaboration, multi-machine collaboration, etc.;

Wide application

Widely used in food, medicine, 3C, daily chemicals, e-commerce and other industries.

Parameters | |

Driver | WARSONCO |

Servo motor | WARSONCO |

Controller | KEBA |

Reducer | LAIFUAL |

Switching power supply | MEAN WELL |

Air source | 0.5-0.8Mpa (vacuum generator) |

Air consumption | 350-450nl/min |

Power supply | 220VAC 50Hz ± 10% |

Maximum power consumption | 5KW |

Total weight | ≈350kg |

Carton size | According to user requirements |

Stacking method | According to user requirements |

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com